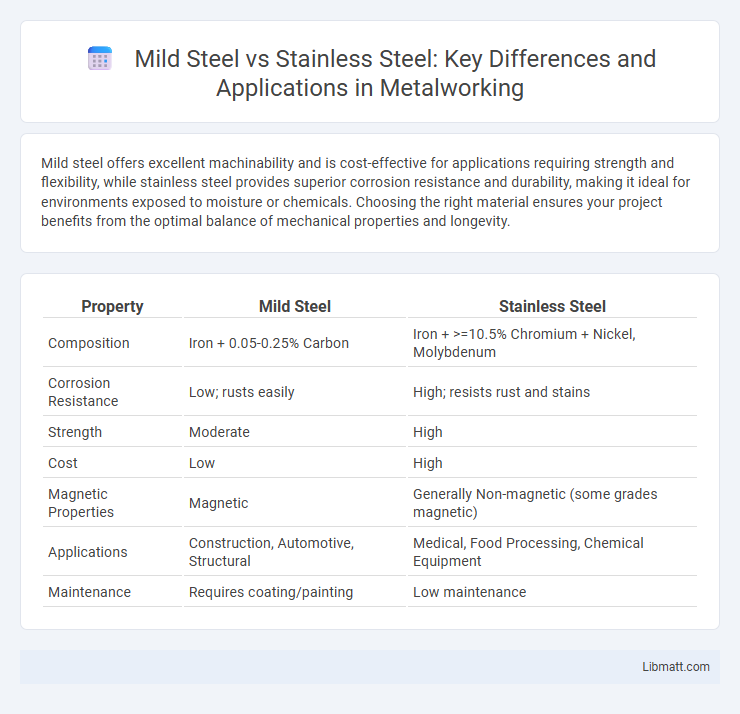

Mild steel offers excellent machinability and is cost-effective for applications requiring strength and flexibility, while stainless steel provides superior corrosion resistance and durability, making it ideal for environments exposed to moisture or chemicals. Choosing the right material ensures your project benefits from the optimal balance of mechanical properties and longevity.

Table of Comparison

| Property | Mild Steel | Stainless Steel |

|---|---|---|

| Composition | Iron + 0.05-0.25% Carbon | Iron + >=10.5% Chromium + Nickel, Molybdenum |

| Corrosion Resistance | Low; rusts easily | High; resists rust and stains |

| Strength | Moderate | High |

| Cost | Low | High |

| Magnetic Properties | Magnetic | Generally Non-magnetic (some grades magnetic) |

| Applications | Construction, Automotive, Structural | Medical, Food Processing, Chemical Equipment |

| Maintenance | Requires coating/painting | Low maintenance |

Introduction to Mild Steel and Stainless Steel

Mild steel, composed primarily of iron with a low carbon content, offers excellent machinability and weldability, making it ideal for construction and automotive applications. Stainless steel, an alloy containing chromium and other elements, provides superior corrosion resistance, strength, and durability, perfect for medical instruments and kitchenware. Understanding the distinct properties of mild steel versus stainless steel helps you select the best material for your project's performance and longevity requirements.

Chemical Composition Differences

Mild steel primarily consists of iron with a carbon content of approximately 0.05% to 0.25%, lacking significant amounts of chromium or nickel. Stainless steel contains a minimum of 10.5% chromium, which imparts corrosion resistance, and often includes nickel, molybdenum, and other alloying elements to enhance strength and durability. The chemical composition differences between mild steel and stainless steel directly influence their corrosion resistance, mechanical properties, and suitability for various industrial applications.

Mechanical Properties Comparison

Mild steel offers higher ductility and machinability compared to stainless steel, making it easier to form and weld in structural applications. Stainless steel exhibits superior tensile strength, hardness, and corrosion resistance, suited for environments requiring durability and exposure to moisture or chemicals. The mechanical performance choice depends on the balance between strength, corrosion resistance, and fabricability required for specific industrial or construction projects.

Corrosion Resistance: Mild Steel vs Stainless Steel

Stainless steel offers superior corrosion resistance compared to mild steel due to its chromium content, which forms a passive oxide layer that protects against rust and oxidation. Mild steel is prone to corrosion when exposed to moisture and harsh environments unless it is coated or painted for protection. Choosing stainless steel for your projects ensures enhanced durability and longevity in corrosive conditions.

Cost and Availability

Mild steel is significantly more cost-effective than stainless steel, making it a preferred choice for large-scale construction and manufacturing projects where budget constraints are critical. It is widely available due to its simple composition primarily of iron and carbon, ensuring easy access and faster delivery times. Stainless steel, containing chromium and other alloys, commands a higher price due to superior corrosion resistance and durability, but its availability can be more limited and dependent on specialized suppliers.

Applications and Common Uses

Mild steel is widely used in construction, automotive parts, and structural applications due to its excellent weldability and cost-effectiveness. Stainless steel is preferred for kitchenware, medical instruments, and chemical processing equipment because of its superior corrosion resistance and durability. Your choice between the two depends on whether strength and affordability or resistance to rust and aesthetics are more critical for your project.

Welding and Fabrication Considerations

Mild steel offers excellent weldability due to its low carbon content, making it ideal for fabrication processes requiring strong, reliable joints with minimal pre-treatment. Stainless steel requires careful welding techniques to prevent corrosion and maintain its strength, often necessitating specific filler materials and post-weld heat treatment to avoid sensitization. Understanding these differences ensures Your fabrication projects achieve optimal durability and performance based on the chosen material.

Maintenance and Longevity

Mild steel requires regular maintenance such as painting or coating to prevent rust and corrosion, which can significantly shorten its lifespan in harsh environments. Stainless steel offers superior corrosion resistance due to its chromium content, reducing the need for frequent upkeep and ensuring longer durability even under extreme conditions. The longevity of stainless steel makes it ideal for applications demanding low maintenance and extended service life.

Environmental Impact and Recyclability

Mild steel has a lower initial environmental impact due to its simpler carbon-based composition and easier smelting process, but stainless steel offers superior recyclability because of its alloyed elements like chromium and nickel, which can be efficiently recovered and reused without significant quality loss. Both materials are widely recyclable, but stainless steel's corrosion resistance extends the lifespan of products, reducing the need for frequent replacements and lowering overall environmental footprint. When selecting between the two, consider your project's sustainability goals and the potential benefits of stainless steel's enhanced recyclability and durability.

Choosing Between Mild Steel and Stainless Steel

Mild steel is preferred for applications requiring good machinability, weldability, and cost-effectiveness, especially in structural and construction projects. Stainless steel offers superior corrosion resistance, making it ideal for environments exposed to moisture or chemicals, such as kitchen equipment or medical instruments. Choosing between mild steel and stainless steel depends on balancing budget constraints with performance needs, particularly corrosion resistance and durability requirements.

mild steel vs stainless steel Infographic

libmatt.com

libmatt.com