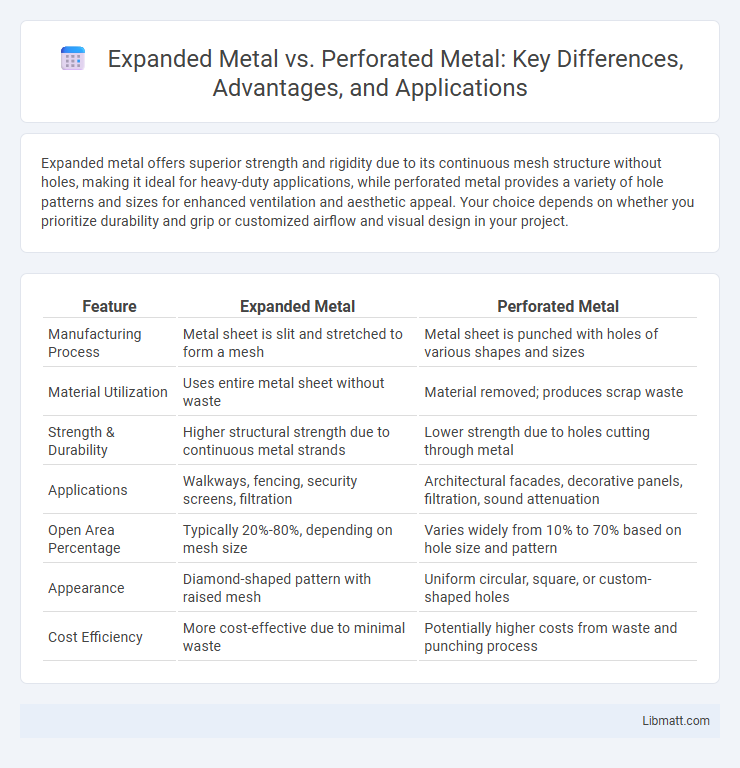

Expanded metal offers superior strength and rigidity due to its continuous mesh structure without holes, making it ideal for heavy-duty applications, while perforated metal provides a variety of hole patterns and sizes for enhanced ventilation and aesthetic appeal. Your choice depends on whether you prioritize durability and grip or customized airflow and visual design in your project.

Table of Comparison

| Feature | Expanded Metal | Perforated Metal |

|---|---|---|

| Manufacturing Process | Metal sheet is slit and stretched to form a mesh | Metal sheet is punched with holes of various shapes and sizes |

| Material Utilization | Uses entire metal sheet without waste | Material removed; produces scrap waste |

| Strength & Durability | Higher structural strength due to continuous metal strands | Lower strength due to holes cutting through metal |

| Applications | Walkways, fencing, security screens, filtration | Architectural facades, decorative panels, filtration, sound attenuation |

| Open Area Percentage | Typically 20%-80%, depending on mesh size | Varies widely from 10% to 70% based on hole size and pattern |

| Appearance | Diamond-shaped pattern with raised mesh | Uniform circular, square, or custom-shaped holes |

| Cost Efficiency | More cost-effective due to minimal waste | Potentially higher costs from waste and punching process |

Introduction to Expanded and Perforated Metal

Expanded metal consists of a single sheet of metal that is simultaneously slit and stretched to create a mesh with diamond-shaped openings, offering high strength and dimensional stability. Perforated metal is produced by punching precise holes in various shapes and patterns into metal sheets, allowing for controlled airflow, filtration, and aesthetic design flexibility. Both materials are widely used in architectural, industrial, and security applications, with expanded metal providing superior load-bearing capabilities and perforated metal offering customizable open-area percentages for specific functional needs.

What is Expanded Metal?

Expanded metal is a type of metal sheet created by simultaneously cutting and stretching the material, resulting in a mesh with diamond-shaped openings. This manufacturing process enhances strength while reducing weight and allows for excellent ventilation and light passage. Expanded metal is widely used in applications such as fencing, grating, and architectural facades due to its durability and versatility.

What is Perforated Metal?

Perforated metal is a sheet material featuring a pattern of holes or slots punched through it for ventilation, filtration, or aesthetic purposes. It offers versatility in applications such as architectural designs, noise control, and machinery guards due to its varied hole shapes and sizes. Your choice between expanded metal and perforated metal depends on factors like strength, weight, and airflow requirements.

Key Differences Between Expanded and Perforated Metal

Expanded metal is created by cutting and stretching a metal sheet to form a mesh-like pattern without removing any material, resulting in increased strength and rigidity. Perforated metal is produced by punching holes of various shapes and sizes into a metal sheet, allowing for precise control over hole patterns and open area. Key differences include manufacturing processes, structural integrity, and applications: expanded metal offers higher strength and better load distribution, while perforated metal provides customizable aesthetics and ventilation options.

Strength and Durability Comparison

Expanded metal offers superior strength-to-weight ratio due to its continuous mesh construction, which distributes loads evenly without weakened points caused by holes or cuts. Perforated metal, while durable, has reduced structural integrity because the punched holes can create stress concentration points that may lead to fatigue under heavy loads. For applications requiring enhanced durability and resistance to impact, expanded metal is often the preferred choice.

Applications of Expanded Metal

Expanded metal is widely used in construction for walkways, stair treads, and security fencing due to its high strength-to-weight ratio and excellent load-bearing capacity. It also serves in architectural facades and sunshades, providing durability and aesthetic appeal while allowing air and light to pass through. Industrial applications include machine guards and ventilation screens, where safety and airflow are critical.

Applications of Perforated Metal

Perforated metal is widely used in architectural facades, acoustic panels, and filtration systems due to its customizable hole patterns and precise hole sizes. It excels in ventilation and noise control applications found in HVAC systems, machinery enclosures, and speaker grills. The material's versatility also makes it ideal for decorative elements, sunshades, and security screens in commercial and industrial settings.

Cost Analysis: Expanded vs Perforated Metal

Expanded metal generally offers a lower cost compared to perforated metal due to its manufacturing process, which involves cutting and stretching a single sheet without waste, resulting in material efficiency and reduced labor costs. Perforated metal requires punching precise holes, leading to higher tooling expenses and increased material waste, thus elevating its overall price. When considering large-scale projects or budgets focused on cost-saving, expanded metal often presents a more economical option without compromising strength or versatility.

Aesthetic and Design Considerations

Expanded metal offers a distinctive, textured pattern that enhances architectural designs with its three-dimensional, mesh-like appearance, providing both visual depth and structural strength. Perforated metal features uniform holes in various shapes and sizes, allowing for sleek, modern aesthetics and customizable light filtration, making it ideal for decorative facades or interior applications. When choosing between the two, your design goals and the desired interplay of light and shadow will guide the optimal selection for aesthetic impact.

Choosing the Right Metal Type for Your Project

Expanded metal offers superior strength and durability due to its continuous mesh structure, making it ideal for heavy-duty applications and enhanced security. Perforated metal provides more versatility with a wide range of hole sizes and patterns, optimizing airflow and aesthetic appeal for decorative and ventilation projects. Your choice depends on balancing strength requirements, design preferences, and functional needs to ensure the metal type perfectly suits your project's demands.

Expanded Metal vs Perforated Metal Infographic

libmatt.com

libmatt.com