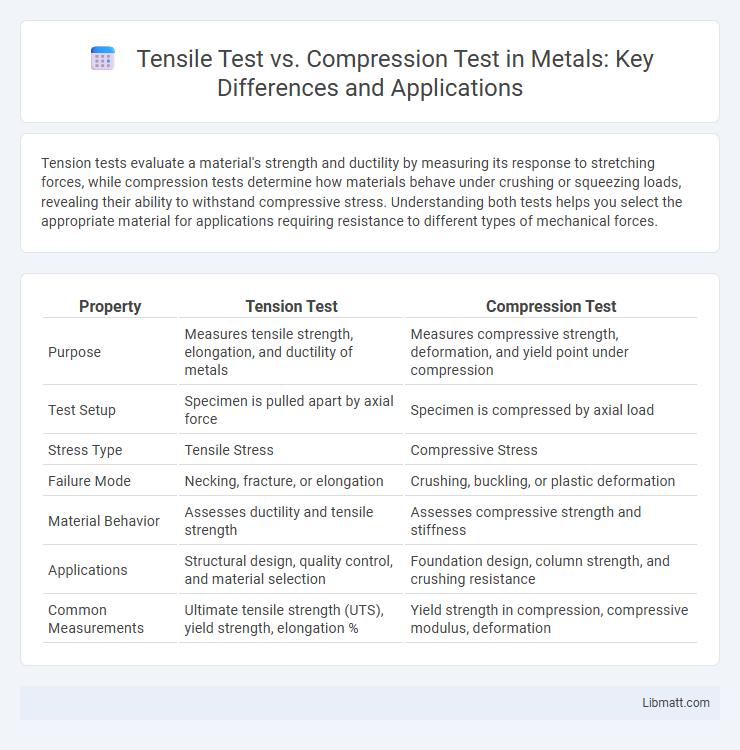

Tension tests evaluate a material's strength and ductility by measuring its response to stretching forces, while compression tests determine how materials behave under crushing or squeezing loads, revealing their ability to withstand compressive stress. Understanding both tests helps you select the appropriate material for applications requiring resistance to different types of mechanical forces.

Table of Comparison

| Property | Tension Test | Compression Test |

|---|---|---|

| Purpose | Measures tensile strength, elongation, and ductility of metals | Measures compressive strength, deformation, and yield point under compression |

| Test Setup | Specimen is pulled apart by axial force | Specimen is compressed by axial load |

| Stress Type | Tensile Stress | Compressive Stress |

| Failure Mode | Necking, fracture, or elongation | Crushing, buckling, or plastic deformation |

| Material Behavior | Assesses ductility and tensile strength | Assesses compressive strength and stiffness |

| Applications | Structural design, quality control, and material selection | Foundation design, column strength, and crushing resistance |

| Common Measurements | Ultimate tensile strength (UTS), yield strength, elongation % | Yield strength in compression, compressive modulus, deformation |

Introduction to Mechanical Testing

Tension test and compression test are fundamental mechanical testing methods used to determine material properties such as strength, ductility, and elasticity. The tension test measures the response of a material under uniaxial tensile load, providing data on tensile strength, yield strength, and elongation. Compression test evaluates material behavior under compressive loads, crucial for materials used in structural applications subjected to crushing or buckling forces.

What is a Tension Test?

A tension test measures the material's response to an applied pulling force, determining properties such as tensile strength, elongation, and Young's modulus. This test helps identify how your material behaves under tension, revealing its ability to withstand stretching or breaking forces. Unlike compression tests that apply a squeezing force, tension tests are essential for understanding the durability and flexibility of materials used in construction and manufacturing.

What is a Compression Test?

A compression test measures a material's behavior under a load that reduces its size by pressing or squeezing it. This test evaluates properties such as compressive strength, yield strength, and modulus of elasticity by applying axial force until the specimen deforms or fails. Compression testing is essential for materials like concrete, metals, and polymers used in structural and mechanical applications.

Key Principles of Tension and Compression Testing

Tension tests evaluate a material's ability to withstand pulling forces by measuring elongation, tensile strength, and ultimate fracture point, revealing ductility and tensile properties essential for structural applications. Compression tests assess how materials respond to crushing forces, determining compressive strength, yield strength, and deformation characteristics critical for materials used in load-bearing components. Understanding these key principles enables you to select the appropriate test to predict material behavior under different stress conditions accurately.

Equipment Used in Tension vs Compression Tests

Tension tests utilize a universal testing machine equipped with grips or fixtures to securely hold the specimen while applying a uniaxial tensile force, measuring parameters like tensile strength and elongation. Compression tests employ a similar universal testing machine but use compression platens or anvils to apply a controlled compressive load, assessing material behavior under crushing or buckling conditions. Your choice between tension and compression testing equipment depends on the specific mechanical properties you need to evaluate for materials or components.

Types of Materials Tested

Tension tests evaluate mechanical properties such as tensile strength and elongation of ductile materials like metals, polymers, and composites by pulling them apart. Compression tests are primarily used to determine compressive strength and deformation behavior of brittle materials such as concrete, ceramics, and certain polymers under crushing loads. Each test method is selected based on material behavior under specific load conditions critical for engineering applications.

Stress-Strain Relationships in Both Tests

Stress-strain relationships in tension and compression tests reveal distinct material behaviors under different loading conditions. In a tension test, the stress-strain curve typically shows elastic deformation followed by yielding and strain hardening until fracture, highlighting tensile strength and ductility. Compression tests often exhibit initial linear elasticity, followed by plastic deformation and potential buckling or crushing, emphasizing compressive strength and material stability under load.

Common Applications in Industry

Tension tests are widely used in industries such as aerospace and automotive to evaluate material strength and ductility under pulling forces, ensuring components withstand operational stresses. Compression tests find common applications in construction and manufacturing sectors, assessing materials like concrete and metals for their ability to resist crushing loads. Both tests provide critical data for quality control and material selection in engineering design and safety assessments.

Advantages and Limitations of Each Test

Tension tests provide accurate measurements of tensile strength, yield strength, and ductility, making them ideal for materials subjected to stretching forces, but they are limited by their inability to simulate compressive stresses and potential specimen deformation. Compression tests excel at evaluating materials under crushing or squashing forces, revealing compressive strength and deformation behavior, though they may suffer from buckling issues in slender specimens and less precise strain measurement. Your choice between tension and compression testing should depend on the specific loading conditions and mechanical properties relevant to your material's application.

Summary: Choosing the Right Test for Your Application

Tension tests measure a material's ability to withstand pulling forces, providing critical data on tensile strength, elongation, and ductility for applications involving stretching or loading. Compression tests evaluate how materials respond to compressive loads, highlighting properties like compressive strength, deformation behavior, and failure modes essential for components subjected to crushing or squashing. Selecting the appropriate test depends on the primary load conditions of the application, ensuring accurate material characterization for structural integrity and performance.

Tension Test vs Compression Test Infographic

libmatt.com

libmatt.com