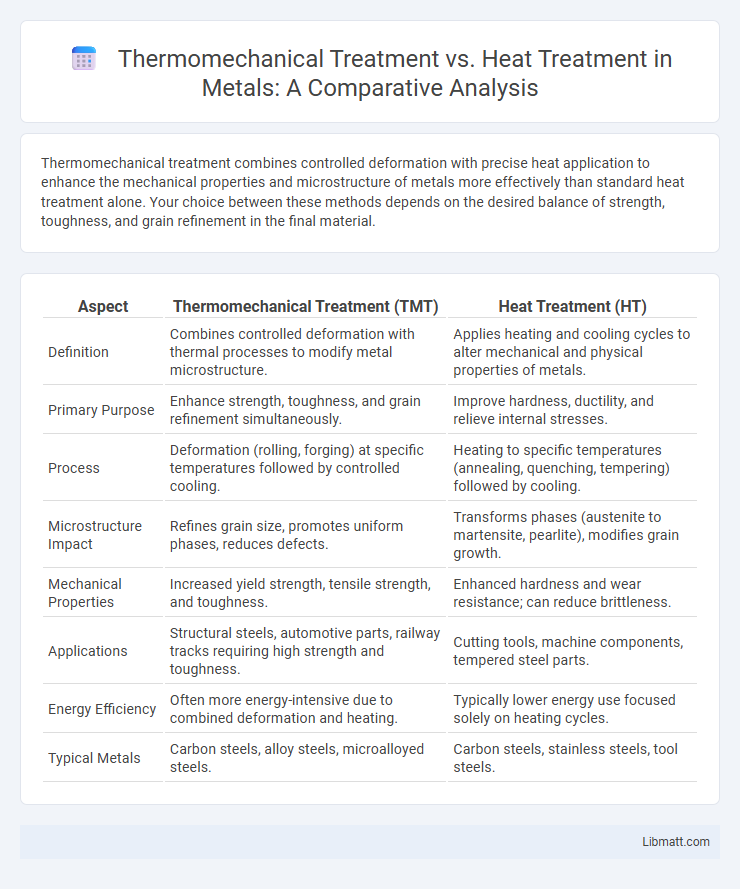

Thermomechanical treatment combines controlled deformation with precise heat application to enhance the mechanical properties and microstructure of metals more effectively than standard heat treatment alone. Your choice between these methods depends on the desired balance of strength, toughness, and grain refinement in the final material.

Table of Comparison

| Aspect | Thermomechanical Treatment (TMT) | Heat Treatment (HT) |

|---|---|---|

| Definition | Combines controlled deformation with thermal processes to modify metal microstructure. | Applies heating and cooling cycles to alter mechanical and physical properties of metals. |

| Primary Purpose | Enhance strength, toughness, and grain refinement simultaneously. | Improve hardness, ductility, and relieve internal stresses. |

| Process | Deformation (rolling, forging) at specific temperatures followed by controlled cooling. | Heating to specific temperatures (annealing, quenching, tempering) followed by cooling. |

| Microstructure Impact | Refines grain size, promotes uniform phases, reduces defects. | Transforms phases (austenite to martensite, pearlite), modifies grain growth. |

| Mechanical Properties | Increased yield strength, tensile strength, and toughness. | Enhanced hardness and wear resistance; can reduce brittleness. |

| Applications | Structural steels, automotive parts, railway tracks requiring high strength and toughness. | Cutting tools, machine components, tempered steel parts. |

| Energy Efficiency | Often more energy-intensive due to combined deformation and heating. | Typically lower energy use focused solely on heating cycles. |

| Typical Metals | Carbon steels, alloy steels, microalloyed steels. | Carbon steels, stainless steels, tool steels. |

Introduction to Material Treatments

Thermomechanical treatment combines controlled mechanical deformation with precise thermal processes to enhance the microstructure and mechanical properties of metals, resulting in improved strength, toughness, and ductility. Heat treatment involves cycles of heating and cooling to alter metal phases, typically optimizing hardness, strength, or machinability without mechanical deformation. Both treatments are critical in metallurgy for tailoring material characteristics to specific engineering applications.

Definition of Heat Treatment

Heat treatment is a controlled process involving the heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. It includes techniques such as annealing, quenching, and tempering to improve hardness, strength, and ductility. Unlike thermomechanical treatment, heat treatment primarily focuses on phase transformations through thermal cycles rather than combined mechanical deformation and thermal exposure.

Overview of Thermomechanical Treatment

Thermomechanical treatment integrates controlled deformation and heat treatment to enhance the mechanical properties and microstructure of metals, particularly steels and aluminum alloys. This process refines grain size, improves strength, toughness, and fatigue resistance by optimizing the combination of thermal and mechanical parameters. Compared to conventional heat treatment, thermomechanical treatment offers superior material performance tailored for aerospace, automotive, and structural applications.

Key Processes in Heat Treatment

Key processes in heat treatment include annealing, quenching, and tempering, which fundamentally alter the microstructure of metals to improve hardness, strength, and ductility. Thermomechanical treatment integrates both thermal cycles and mechanical deformation, such as controlled rolling or forging, to enhance mechanical properties through grain refinement and phase transformation. Heat treatment primarily relies on temperature control and time, whereas thermomechanical treatment combines strain and temperature for superior material performance.

Thermomechanical Treatment Procedures

Thermomechanical treatment procedures integrate controlled deformation and precise temperature regulation to enhance material properties such as strength, toughness, and grain refinement, surpassing traditional heat treatment methods that rely solely on thermal cycles. These processes often involve hot rolling, forging, or controlled cooling to manipulate microstructures at the molecular level, optimizing mechanical performance and durability. By tailoring thermomechanical treatment steps, your components can achieve superior fatigue resistance and improved structural integrity compared to conventional heat-treated materials.

Microstructural Changes: Heat vs. Thermomechanical Treatment

Thermomechanical treatment combines mechanical deformation with controlled heating to refine grain structure, enhance dislocation density, and promote dynamic recrystallization, resulting in improved strength and toughness compared to conventional heat treatment. Heat treatment alone primarily alters microstructure by phase transformations, such as austenitizing and tempering, modifying hardness and ductility without significant grain size refinement. The integration of plastic deformation during thermomechanical processing leads to more uniform and finer microstructures, optimizing mechanical performance in metals and alloys.

Mechanical Properties Comparison

Thermomechanical treatment enhances mechanical properties by combining precise deformation and controlled heat exposure, resulting in finer microstructures and improved strength, toughness, and ductility compared to conventional heat treatment. Heat treatment primarily alters mechanical properties through thermal cycles like quenching and tempering, which may lead to less uniform grain refinement. Your material's performance is optimized with thermomechanical processing, especially for demanding applications requiring superior mechanical resilience.

Applications in Industry

Thermomechanical treatment enhances material properties by combining deformation and controlled heat processes, making it ideal for industries requiring high-strength components such as automotive, aerospace, and heavy machinery manufacturing. Heat treatment primarily alters microstructure through heating and cooling cycles to improve hardness, toughness, and wear resistance, commonly used in steel manufacturing, tool production, and construction equipment. Your selection between these treatments depends on the specific performance requirements and application environments within industrial sectors.

Advantages and Limitations

Thermomechanical treatment enhances material properties by combining deformation with controlled heat application, resulting in improved strength, toughness, and fine microstructure compared to conventional heat treatment, which primarily relies on heating and cooling cycles to alter material phases. Your choice depends on the desired mechanical performance and production constraints, as thermomechanical treatment offers superior strength and durability but involves complex processing and higher costs, while heat treatment is simpler, more cost-effective, yet may provide less optimized mechanical properties. Limitations of thermomechanical treatment include equipment complexity and process control challenges, whereas heat treatment can lead to residual stresses and less uniform microstructures.

Conclusion and Future Trends

Thermomechanical treatment offers enhanced mechanical properties by combining deformation and precise thermal cycles, resulting in refined microstructures compared to conventional heat treatment. Future trends point toward integrating advanced simulation techniques and machine learning to optimize process parameters, improve energy efficiency, and tailor material properties for specific applications. Continued research emphasizes sustainable practices and the development of novel alloys that benefit from combined thermomechanical and heat treatment processes.

thermomechanical treatment vs heat treatment Infographic

libmatt.com

libmatt.com