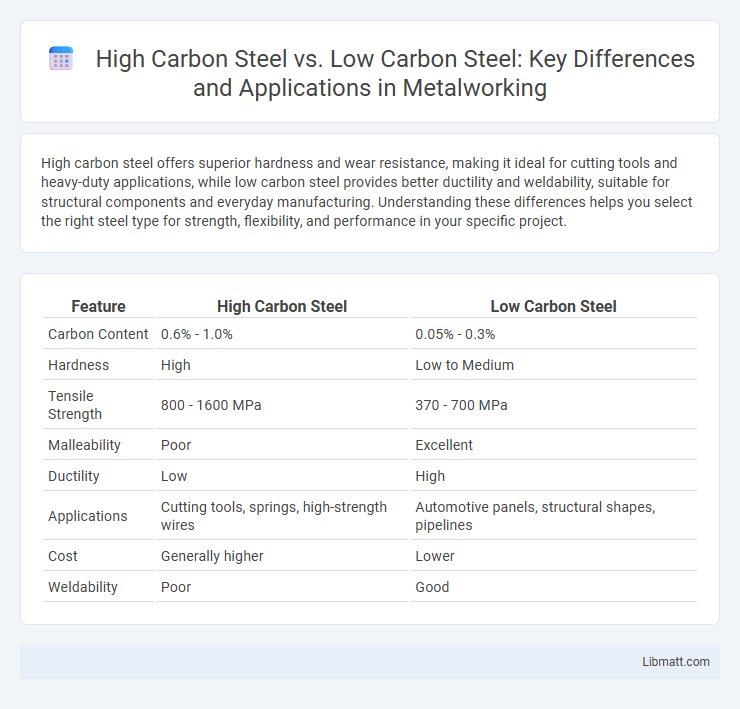

High carbon steel offers superior hardness and wear resistance, making it ideal for cutting tools and heavy-duty applications, while low carbon steel provides better ductility and weldability, suitable for structural components and everyday manufacturing. Understanding these differences helps you select the right steel type for strength, flexibility, and performance in your specific project.

Table of Comparison

| Feature | High Carbon Steel | Low Carbon Steel |

|---|---|---|

| Carbon Content | 0.6% - 1.0% | 0.05% - 0.3% |

| Hardness | High | Low to Medium |

| Tensile Strength | 800 - 1600 MPa | 370 - 700 MPa |

| Malleability | Poor | Excellent |

| Ductility | Low | High |

| Applications | Cutting tools, springs, high-strength wires | Automotive panels, structural shapes, pipelines |

| Cost | Generally higher | Lower |

| Weldability | Poor | Good |

Introduction to Carbon Steel Grading

Carbon steel grading is primarily determined by its carbon content, which significantly influences its hardness, strength, and ductility. High carbon steel contains approximately 0.6% to 1.0% carbon, making it ideal for applications requiring high strength and wear resistance, such as cutting tools and springs. Low carbon steel, with less than 0.3% carbon, offers greater flexibility and weldability, making it suitable for automotive panels and structural components where formability is crucial.

Chemical Composition: High vs Low Carbon Steel

High carbon steel typically contains 0.6% to 1.0% carbon, providing increased hardness and strength due to its higher carbon content, while low carbon steel contains less than 0.3% carbon, resulting in greater ductility and machinability. The chemical composition of high carbon steel often includes higher levels of manganese and smaller amounts of other alloying elements to enhance wear resistance, whereas low carbon steel's composition emphasizes iron with minimal carbon and trace elements for improved formability. Understanding your application helps determine which carbon steel type optimizes performance based on the precise chemical composition differences.

Mechanical Properties Comparison

High carbon steel exhibits significantly higher tensile strength and hardness due to its increased carbon content, typically ranging from 0.6% to 1.0%, making it ideal for applications requiring wear resistance and durability. In contrast, low carbon steel, with carbon content below 0.3%, offers greater ductility and malleability, allowing for easier machining and forming processes but lower strength. The mechanical properties of high carbon steel favor structural uses where hardness is critical, whereas low carbon steel suits projects demanding flexibility and impact resistance.

Strength and Hardness Differences

High carbon steel contains approximately 0.6% to 1.0% carbon, resulting in greater strength and hardness compared to low carbon steel, which typically has less than 0.3% carbon. The increased carbon content in high carbon steel enhances its ability to withstand wear and deformation, making it ideal for cutting tools and high-strength applications. Understanding these differences helps you choose the appropriate steel type based on performance requirements for strength and hardness.

Weldability and Workability Factors

High carbon steel offers superior strength and wear resistance but has lower weldability and workability due to its higher carbon content, making it prone to cracking during welding and difficult to shape. Low carbon steel features excellent weldability and workability because its lower carbon content reduces the risk of weld defects and allows easier forming and machining processes. When choosing between these steels, consider your project's requirements for strength versus ease of fabrication and welding.

Common Applications of High Carbon Steel

High carbon steel is commonly used in applications requiring high strength and hardness, such as cutting tools, springs, and high-wear components like knives and blades. Its enhanced carbon content provides superior wear resistance, making it ideal for industrial machinery parts and automotive components subjected to heavy stress. Choosing high carbon steel for Your tools ensures durability and prolonged sharpness in demanding work environments.

Typical Uses for Low Carbon Steel

Low carbon steel is commonly used in construction materials, automotive body panels, and consumer goods due to its excellent ductility and weldability. Its lower carbon content makes it softer and easier to shape, ideal for manufacturing pipes, sheets, and structural beams. You can rely on low carbon steel for applications requiring flexibility and corrosion resistance without compromising strength.

Cost and Availability Considerations

High carbon steel typically costs more than low carbon steel due to its higher carbon content and manufacturing process, which enhances hardness and wear resistance but reduces ductility. Low carbon steel is widely available and more affordable, making it suitable for mass production and applications requiring malleability and ease of fabrication. The price difference and supply chain factors influence the choice between these steels depending on project budgets and material performance needs.

Corrosion Resistance and Maintenance

High carbon steel contains approximately 0.6% to 1.0% carbon, resulting in higher hardness but lower corrosion resistance compared to low carbon steel, which has roughly 0.05% to 0.25% carbon content. The increased carbon in high carbon steel accelerates oxidation, requiring more frequent maintenance such as rust removal and protective coatings to prevent degradation. Low carbon steel offers better corrosion resistance and generally demands less maintenance, making it suitable for applications exposed to moisture or corrosive environments.

Choosing the Right Steel for Your Project

High carbon steel offers superior hardness and wear resistance, making it ideal for cutting tools, blades, and heavy-duty machinery parts. Low carbon steel provides greater ductility and weldability, suitable for automotive panels, structural components, and manufacturing requiring flexibility. Selecting the right steel depends on balancing strength requirements with machining and forming capabilities specific to your project's demands.

High Carbon Steel vs Low Carbon Steel Infographic

libmatt.com

libmatt.com