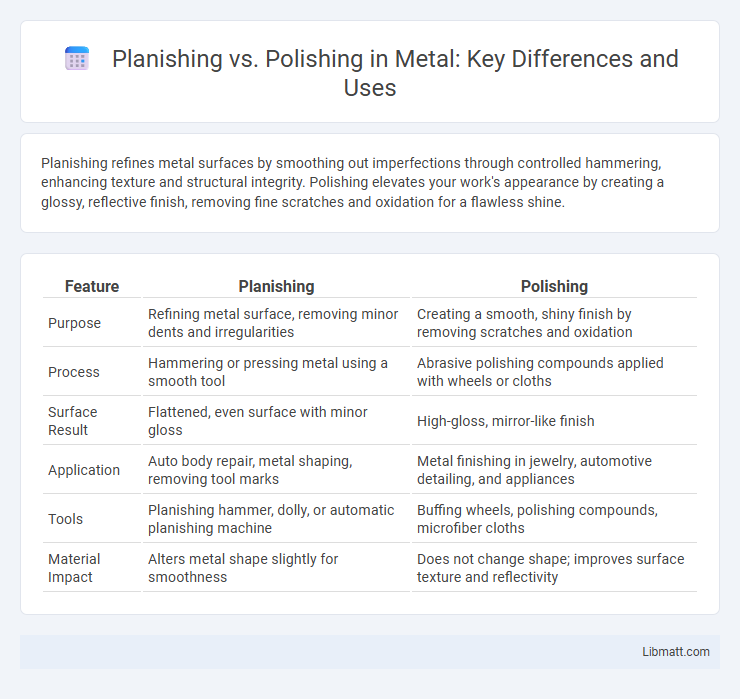

Planishing refines metal surfaces by smoothing out imperfections through controlled hammering, enhancing texture and structural integrity. Polishing elevates your work's appearance by creating a glossy, reflective finish, removing fine scratches and oxidation for a flawless shine.

Table of Comparison

| Feature | Planishing | Polishing |

|---|---|---|

| Purpose | Refining metal surface, removing minor dents and irregularities | Creating a smooth, shiny finish by removing scratches and oxidation |

| Process | Hammering or pressing metal using a smooth tool | Abrasive polishing compounds applied with wheels or cloths |

| Surface Result | Flattened, even surface with minor gloss | High-gloss, mirror-like finish |

| Application | Auto body repair, metal shaping, removing tool marks | Metal finishing in jewelry, automotive detailing, and appliances |

| Tools | Planishing hammer, dolly, or automatic planishing machine | Buffing wheels, polishing compounds, microfiber cloths |

| Material Impact | Alters metal shape slightly for smoothness | Does not change shape; improves surface texture and reflectivity |

Understanding Planishing and Polishing

Planishing involves gently smoothing and shaping metal surfaces through repetitive hammering to refine contour and remove imperfections, commonly used in metalworking and automotive restoration. Polishing is the process of creating a smooth and shiny surface on metal by abrasion with fine materials to enhance aesthetic appeal and prevent corrosion. Both techniques improve metal surfaces but serve distinct purposes: planishing adjusts form and texture, while polishing focuses on surface finish and luster.

Key Differences Between Planishing and Polishing

Planishing involves repeatedly hammering metal to smooth out surface imperfections and refine shape, primarily used in metalworking and automotive restoration. Polishing focuses on creating a high-gloss finish by removing scratches and oxidation through abrasive compounds and buffing. The key difference lies in planishing shaping and strengthening the metal, while polishing enhances surface appearance and shine.

The Planishing Process Explained

Planishing is a metalworking technique that involves repeatedly striking the surface of a metal sheet with a polished hammer or planishing tool to smooth out irregularities and refine its shape. This process strengthens the metal by compressing its surface, improving its durability and aesthetic finish without removing material, unlike polishing which primarily enhances shine. Skilled artisans use planishing to create seamless curves and subtle textures, making it essential in custom automotive bodywork and fine metal sculpture.

Polishing Techniques and Methods

Polishing techniques include mechanical, chemical, and electrochemical methods, each designed to enhance surface smoothness and shine at microscopic levels. Mechanical polishing uses abrasives like sandpaper, polishing compounds, or buffing wheels to remove surface imperfections and achieve a reflective finish. Chemical and electrochemical polishing involve controlled material removal through reactions, producing highly uniform, corrosion-resistant surfaces ideal for metals and precision components.

Tools Required for Planishing

Planishing requires specialized tools such as a planishing hammer and a smooth, polished anvil or dollies to shape and smooth metal surfaces. These tools are designed to gently stretch and refine metal by controlled, light hammering to remove imperfections without stretching the material excessively. Unlike polishing, which uses abrasives or buffing wheels, planishing emphasizes precise hammering techniques with these specific hand tools for metal finishing.

Essential Equipment for Polishing

Essential equipment for polishing includes polishing pads, buffing wheels, and various types of polishing compounds designed to achieve different levels of shine and smoothness. Electric or pneumatic polishers are commonly used to provide consistent speed and pressure, ensuring an even finish on metal or automotive surfaces. Proper safety gear such as gloves, masks, and eye protection is crucial to protect against dust and chemical exposure during the polishing process.

Common Applications of Planishing

Planishing is commonly applied in automotive and metalworking industries to smooth out minor surface imperfections and restore the shape of sheet metal panels. It is essential for repairing dents on car bodies, aircraft skins, and metal sculptures, where precise surface finishing and fine detailing are required. This technique enhances structural integrity while preparing surfaces for final finishing processes such as painting or plating.

Typical Uses for Polishing in Metalwork

Polishing in metalwork is typically used to enhance surface smoothness and achieve a reflective, mirror-like finish on metals such as stainless steel, aluminum, and brass. It prepares metal surfaces for aesthetic enhancement, corrosion resistance, and improved wear properties in applications including automotive parts, jewelry, and kitchenware. Your project benefits from polishing when a clean, smooth, and visually appealing metal surface is required for both functional and decorative purposes.

Pros and Cons: Planishing vs Polishing

Planishing enhances metal surface smoothness by gently hammering, which strengthens the material and corrects imperfections, but it is time-consuming and requires skill to avoid distorting the metal. Polishing improves shine and removes surface scratches quickly, offering a high-gloss finish ideal for aesthetic purposes, though it can thin the metal surface and may not fix structural flaws. Choosing between planishing and polishing depends on whether strength and shape correction or surface smoothness and appearance are the primary goals.

Choosing the Right Technique for Your Project

Planishing involves gently hammering metal to smooth out imperfections and refine shape, ideal for projects needing precise surface contouring with subtle texture. Polishing uses abrasives and buffing tools to create a shiny, reflective finish, best suited for enhancing aesthetics and surface smoothness on metals, plastics, or wood. Selecting the right technique depends on whether the project requires structural shaping and textural refinement (planishing) or surface luster and gloss (polishing).

Planishing vs Polishing Infographic

libmatt.com

libmatt.com