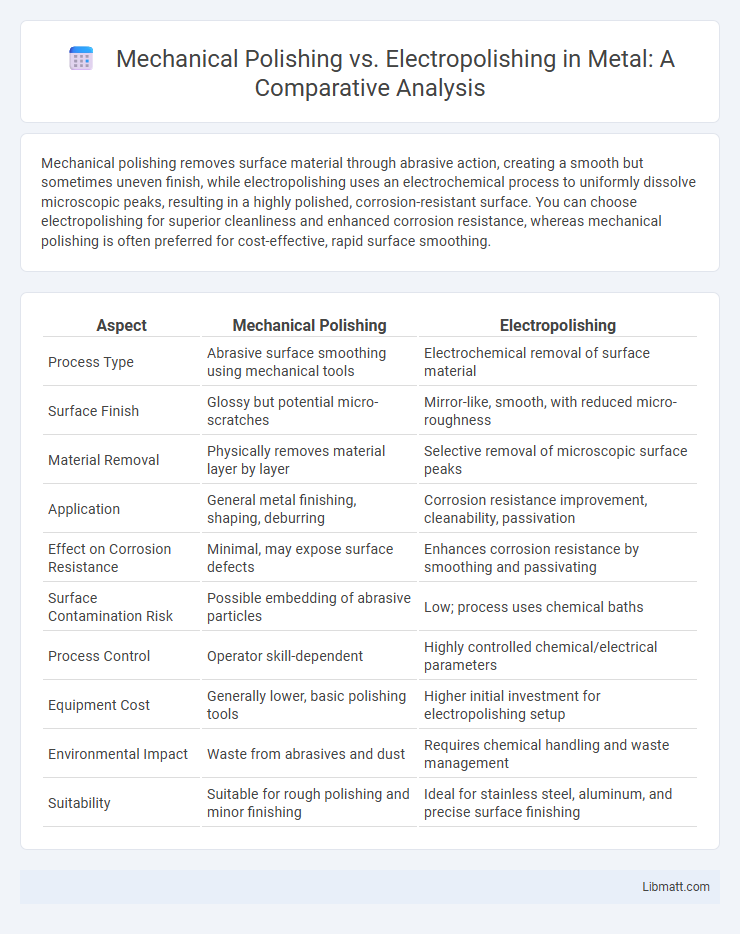

Mechanical polishing removes surface material through abrasive action, creating a smooth but sometimes uneven finish, while electropolishing uses an electrochemical process to uniformly dissolve microscopic peaks, resulting in a highly polished, corrosion-resistant surface. You can choose electropolishing for superior cleanliness and enhanced corrosion resistance, whereas mechanical polishing is often preferred for cost-effective, rapid surface smoothing.

Table of Comparison

| Aspect | Mechanical Polishing | Electropolishing |

|---|---|---|

| Process Type | Abrasive surface smoothing using mechanical tools | Electrochemical removal of surface material |

| Surface Finish | Glossy but potential micro-scratches | Mirror-like, smooth, with reduced micro-roughness |

| Material Removal | Physically removes material layer by layer | Selective removal of microscopic surface peaks |

| Application | General metal finishing, shaping, deburring | Corrosion resistance improvement, cleanability, passivation |

| Effect on Corrosion Resistance | Minimal, may expose surface defects | Enhances corrosion resistance by smoothing and passivating |

| Surface Contamination Risk | Possible embedding of abrasive particles | Low; process uses chemical baths |

| Process Control | Operator skill-dependent | Highly controlled chemical/electrical parameters |

| Equipment Cost | Generally lower, basic polishing tools | Higher initial investment for electropolishing setup |

| Environmental Impact | Waste from abrasives and dust | Requires chemical handling and waste management |

| Suitability | Suitable for rough polishing and minor finishing | Ideal for stainless steel, aluminum, and precise surface finishing |

Introduction to Surface Finishing Techniques

Mechanical polishing and electropolishing are two key surface finishing techniques used to enhance metal surfaces. Mechanical polishing physically removes surface irregularities and contaminants through abrasion, resulting in a smooth and shiny finish, while electropolishing uses electrochemical processes to dissolve a thin layer of metal, improving surface smoothness and corrosion resistance. Your choice between these methods depends on factors such as material type, desired surface quality, and application requirements.

What is Mechanical Polishing?

Mechanical polishing is a surface finishing process that uses abrasive materials and mechanical force to smooth and shine metal surfaces by removing microscopic imperfections. The process enhances surface texture, improves corrosion resistance, and prepares metals for subsequent treatments like coating or welding. Your choice of mechanical polishing depends on factors such as metal type, desired finish, and application requirements.

What is Electropolishing?

Electropolishing is an electrochemical process that smooths and improves the surface finish of metal by selectively removing microscopic peaks through anodic dissolution. This technique enhances corrosion resistance, reduces surface roughness, and provides a bright, reflective finish, making it ideal for stainless steel and other alloys. Unlike mechanical polishing, electropolishing eliminates contaminants and microscopic burrs without mechanical abrasion, preserving material integrity and surface geometry.

Key Differences Between Mechanical and Electropolishing

Mechanical polishing relies on abrasive materials to physically remove surface imperfections and create a smooth finish, while electropolishing uses an electrochemical process to dissolve surface layers for enhanced smoothness and corrosion resistance. Mechanical polishing can introduce micro-scratches and stress on the metal surface, whereas electropolishing produces a uniformly smooth, passive oxide layer that improves cleanliness and durability. Electropolishing is particularly effective for complex geometries and stainless steel alloys, offering superior surface quality and reduced contamination risk compared to mechanical methods.

Surface Finish Quality Comparison

Mechanical polishing achieves surface finish by physically abrading the material, often resulting in micro-scratches and a less uniform texture, while electropolishing uses electrochemical processes to remove a thin, controlled layer, producing a smoother, brighter, and more consistent surface finish. Electropolishing can achieve surface roughness values as low as Ra 0.05 um, significantly improving corrosion resistance and cleanliness compared to mechanical polishing, which typically yields roughness values around Ra 0.2-0.5 um. The superior finish of electropolished surfaces makes it preferable for medical devices, semiconductor components, and high-precision applications where surface integrity is critical.

Impact on Material Integrity

Mechanical polishing removes surface imperfections through abrasive action, potentially introducing micro-scratches and residual stress that may weaken material integrity. Electropolishing, by selectively dissolving surface layers at the microscopic level, enhances corrosion resistance and maintains structural properties without mechanical strain. Your choice directly affects the durability and performance of metal components in critical applications.

Efficiency and Process Time

Mechanical polishing typically requires longer process times due to the manual or machine-driven abrasion steps involved, often taking several minutes to hours depending on surface area and desired finish. Electropolishing offers higher efficiency by rapidly removing microscopic layers of material through electrochemical action, significantly reducing processing time to minutes while achieving a smoother, more consistent surface. Industrial applications favor electropolishing for large-scale, high-precision tasks due to its faster throughput and uniform results compared to mechanical polishing.

Environmental and Safety Considerations

Mechanical polishing generates abrasive waste and dust that require proper disposal and protective measures to prevent respiratory issues and environmental contamination. Electropolishing involves the use of hazardous chemicals such as acids and electrolytes, necessitating careful handling, proper ventilation, and waste neutralization to minimize chemical exposure and environmental risks. Both processes demand adherence to safety protocols and environmental regulations to ensure worker safety and ecological protection.

Cost Implications of Each Method

Mechanical polishing typically incurs lower initial costs due to simpler equipment and less specialized labor, making it cost-effective for routine surface finishing tasks. Electropolishing, while more expensive upfront because of specialized power supplies, chemicals, and safety measures, offers superior surface quality and corrosion resistance that can reduce long-term maintenance costs. Evaluating project scale and required surface finish quality is essential when considering the cost-effectiveness of mechanical polishing versus electropolishing.

Selecting the Right Polishing Method for Your Application

Mechanical polishing involves abrasive techniques to physically smooth surfaces, ideal for applications requiring rapid material removal and shaping. Electropolishing uses electrochemical processes to dissolve microscopic surface peaks, providing superior corrosion resistance and a uniform, mirror-like finish. Your choice depends on factors like desired surface finish, material type, and specific industry requirements such as biomedical, aerospace, or food processing standards.

Mechanical polishing vs electropolishing Infographic

libmatt.com

libmatt.com