Dynamic balancing ensures that rotating components maintain equilibrium across multiple axes during motion to prevent vibrations, while static balancing focuses on distributing mass evenly around a single axis at rest. Your machinery's performance and longevity improve significantly when dynamic balancing addresses both mass and inertia, unlike static balancing which only corrects for mass distribution.

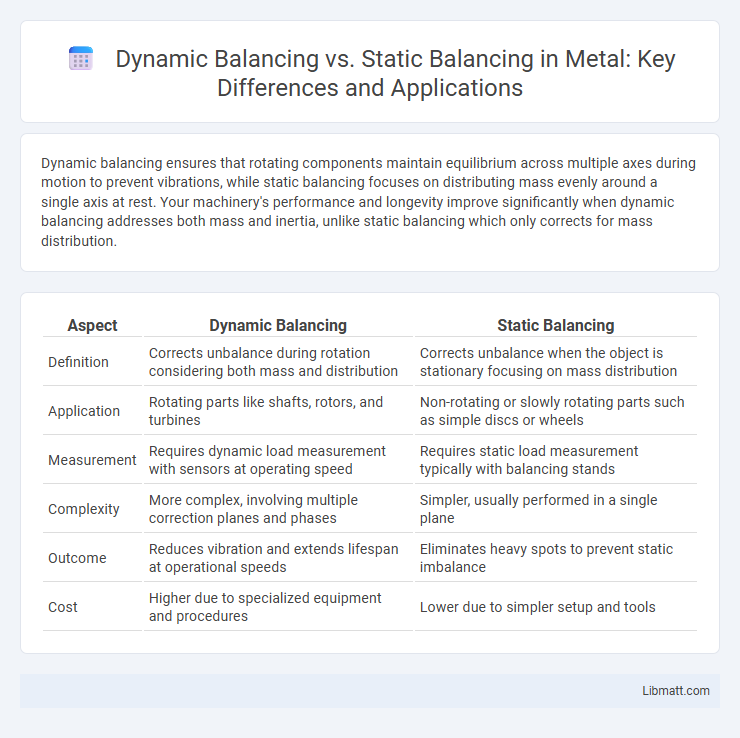

Table of Comparison

| Aspect | Dynamic Balancing | Static Balancing |

|---|---|---|

| Definition | Corrects unbalance during rotation considering both mass and distribution | Corrects unbalance when the object is stationary focusing on mass distribution |

| Application | Rotating parts like shafts, rotors, and turbines | Non-rotating or slowly rotating parts such as simple discs or wheels |

| Measurement | Requires dynamic load measurement with sensors at operating speed | Requires static load measurement typically with balancing stands |

| Complexity | More complex, involving multiple correction planes and phases | Simpler, usually performed in a single plane |

| Outcome | Reduces vibration and extends lifespan at operational speeds | Eliminates heavy spots to prevent static imbalance |

| Cost | Higher due to specialized equipment and procedures | Lower due to simpler setup and tools |

Introduction to Dynamic and Static Balancing

Dynamic balancing addresses imbalances caused by uneven mass distribution and rotational forces in moving parts, ensuring smoother operation and reduced vibration. Static balancing corrects imbalances when the object is stationary, focusing on weight distribution around the axis of rotation to prevent wobbling. Understanding these techniques helps you maintain machinery efficiency and prolong component lifespan.

What is Static Balancing?

Static balancing is the process of ensuring that an object's mass is evenly distributed around its axis of rotation so it remains stable when stationary. This technique identifies and corrects imbalance by placing weights or removing material to prevent the object from tilting or wobbling when at rest. Your equipment benefits from static balancing by reducing vibrations and enhancing performance during operation.

What is Dynamic Balancing?

Dynamic balancing is the process of correcting mass distribution in rotating machinery to reduce vibrations caused by imbalances during motion. Unlike static balancing, which addresses imbalances only when the object is stationary, dynamic balancing accounts for forces generated at operational speeds by measuring and compensating for uneven mass placement along multiple planes. This ensures smoother operation, extended equipment life, and improved performance in applications such as turbines, compressors, and automotive wheels.

Key Differences Between Dynamic and Static Balancing

Dynamic balancing corrects imbalance in rotating components by addressing forces in multiple planes during motion, while static balancing targets imbalance in a single plane when the object is at rest. Static balancing primarily eliminates centrifugal forces caused by mass distribution, whereas dynamic balancing compensates for both centrifugal and couple forces to ensure smooth operation. The accuracy of dynamic balancing is crucial for high-speed machinery to prevent vibration, whereas static balancing suffices for lower-speed or simpler rotating parts.

Importance of Balancing in Rotating Machinery

Balancing is crucial in rotating machinery to prevent vibrations that cause wear, reduce performance, and increase maintenance costs. Static balancing ensures the mass distribution is even around the axis of rotation when the object is stationary, while dynamic balancing corrects imbalances that occur during actual rotation at operational speeds. Your machinery's longevity and operational efficiency depend on precise dynamic balancing to handle forces generated during real-time motion, unlike static balancing which only addresses balance at rest.

Applications of Static Balancing

Static balancing is commonly applied in scenarios where rotating components must maintain equilibrium at rest to prevent vibrations and premature wear, such as in fans, turbines, and automotive wheels. This method ensures that the center of mass aligns with the axis of rotation, reducing the risk of uneven stress and extending the lifespan of machinery. Your equipment benefits from static balancing by achieving smoother operation and minimizing maintenance costs in low to moderate speed applications.

Applications of Dynamic Balancing

Dynamic balancing is crucial in rotating machinery such as turbines, engines, and automotive wheels, where it reduces vibrations and prevents premature wear by correcting imbalances occurring at multiple planes. It is widely applied in high-speed equipment like turbochargers, crankshafts, and rotors to ensure smooth operation and extend component lifespan. Unlike static balancing, dynamic balancing addresses both mass distribution and the resulting gyroscopic forces during rotation, making it essential for complex, multi-plane rotating systems.

Advantages and Disadvantages: Static vs Dynamic Balancing

Static balancing ensures even weight distribution around a single axis, reducing vibrations in rotating parts but cannot compensate for dynamic forces caused by shaft bending or misalignment. Dynamic balancing addresses both static and dynamic imbalances by correcting weight distribution across multiple planes, enhancing smoother operation and reducing wear in high-speed machinery, though it requires more complex equipment and higher costs. Choosing between static and dynamic balancing depends on the application's speed, precision requirements, and budget constraints, with dynamic balancing preferred for high-performance rotors and static balancing suitable for simpler, low-speed components.

Common Issues Caused by Poor Balancing

Poor dynamic balancing can cause vibrations, uneven wear, and noise in rotating machinery, leading to decreased equipment lifespan and increased maintenance costs. Static imbalance often results in excessive radial forces, shaft bending, and bearing damage, which affect machine stability and operational efficiency. Ensuring proper balancing enhances your machinery's performance, reduces downtime, and prevents costly repairs.

Selecting the Right Balancing Method for Your Needs

Choosing between dynamic balancing and static balancing depends on the specific rotor configuration and operational conditions. Dynamic balancing is essential for rotating machinery with complex geometries or high-speed applications to counteract unbalanced forces in multiple planes, ensuring smoother performance and reduced vibration. Static balancing suits simpler, single-plane rotors where the primary concern is weight distribution, providing cost-effective solutions for low-speed or less demanding environments.

dynamic balancing vs static balancing Infographic

libmatt.com

libmatt.com