Copper clad steel offers enhanced strength and durability compared to pure copper while maintaining good electrical conductivity, making it ideal for applications requiring both mechanical toughness and efficient conductivity. Your choice depends on whether you prioritize cost-effectiveness and tensile strength (copper clad steel) or superior conductivity and corrosion resistance (pure copper).

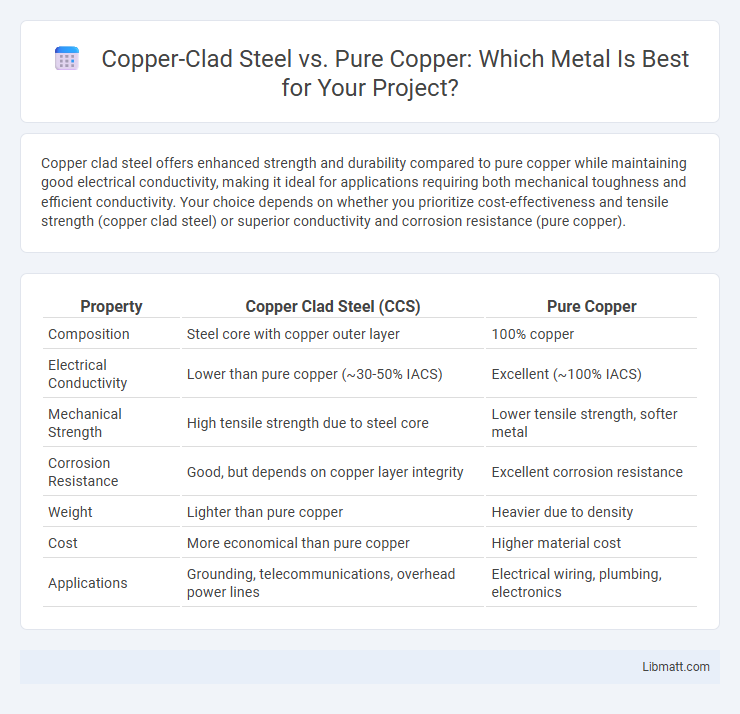

Table of Comparison

| Property | Copper Clad Steel (CCS) | Pure Copper |

|---|---|---|

| Composition | Steel core with copper outer layer | 100% copper |

| Electrical Conductivity | Lower than pure copper (~30-50% IACS) | Excellent (~100% IACS) |

| Mechanical Strength | High tensile strength due to steel core | Lower tensile strength, softer metal |

| Corrosion Resistance | Good, but depends on copper layer integrity | Excellent corrosion resistance |

| Weight | Lighter than pure copper | Heavier due to density |

| Cost | More economical than pure copper | Higher material cost |

| Applications | Grounding, telecommunications, overhead power lines | Electrical wiring, plumbing, electronics |

Introduction to Copper Clad Steel and Pure Copper

Copper Clad Steel (CCS) combines a steel core with a copper outer layer, offering enhanced strength and corrosion resistance while maintaining excellent electrical conductivity. Pure copper, known for its superior electrical and thermal conductivity, provides optimal performance in electrical wiring and electronic components but lacks the mechanical strength of CCS. The choice between Copper Clad Steel and Pure Copper depends on the application's need for durability, conductivity, and cost-effectiveness.

Composition and Manufacturing Process

Copper clad steel consists of a steel core coated with a thin layer of pure copper, combining the strength of steel with the conductivity and corrosion resistance of copper. Pure copper is manufactured by refining and casting copper cathodes, resulting in a homogeneous metal with excellent electrical and thermal conductivity. Your choice depends on whether you prioritize mechanical strength or pure copper's optimal conductivity for applications such as electrical wiring and grounding.

Electrical Conductivity Comparison

Copper clad steel offers lower electrical conductivity compared to pure copper due to the steel core, which is less conductive. Pure copper exhibits approximately 100% conductivity on the International Annealed Copper Standard (IACS) scale, while copper clad steel typically ranges between 30-50%, depending on the copper thickness. When optimizing your electrical applications, choosing pure copper ensures maximum efficiency and minimal energy loss.

Mechanical Strength and Durability

Copper Clad Steel (CCS) offers superior mechanical strength and durability compared to pure copper due to its steel core, making it more resistant to stretching, bending, and breakage under stress. This enhanced robustness is ideal for applications requiring long-lasting performance in harsh environments, as CCS maintains conductivity while significantly improving tensile strength. Your choice between CCS and pure copper should consider the balance between electrical conductivity and mechanical resilience needed for your specific use case.

Corrosion Resistance and Longevity

Copper clad steel offers enhanced corrosion resistance due to its steel core's strength combined with a protective copper outer layer, making it more durable in harsh environments. Pure copper, while highly resistant to corrosion, tends to be softer and more prone to mechanical wear over time. Your choice depends on whether you prioritize longevity and mechanical strength (copper clad steel) or optimal electrical conductivity and natural corrosion resistance (pure copper).

Weight and Flexibility Differences

Copper clad steel is significantly lighter than pure copper due to its steel core, making it an ideal choice when reducing weight is essential. While pure copper offers superior flexibility and excellent conductivity, the steel core in copper clad steel provides added strength but reduces pliability. Your choice between the two depends on whether you prioritize lightweight durability or maximum flexibility for your application.

Cost-Effectiveness and Economic Considerations

Copper clad steel offers a more cost-effective alternative to pure copper due to its lower raw material costs while maintaining adequate conductivity for many applications. The economic advantage of copper clad steel is particularly notable in large-scale projects where budget constraints prioritize durability and performance over maximum conductivity. Pure copper, despite its higher cost, provides superior electrical conductivity and corrosion resistance, justifying its expense in critical high-performance environments.

Common Applications and Use Cases

Copper clad steel offers high tensile strength and corrosion resistance, making it ideal for electrical grounding, telecommunications grounding wires, and overhead transmission lines where durability is critical. Pure copper exhibits superior electrical conductivity and flexibility, commonly used in electrical wiring, circuit boards, and electromagnetic shielding applications requiring optimal conductivity. Both materials find use in power distribution systems, but the choice depends on balancing conductivity needs with mechanical strength and cost considerations.

Environmental Impact and Sustainability

Copper clad steel offers a sustainable advantage by reducing the demand for pure copper, a resource-intensive metal with significant environmental mining impacts. The steel core in copper clad steel decreases the overall copper usage, conserving natural resources and lowering energy consumption associated with copper extraction and refining. Pure copper, while highly recyclable, involves higher carbon emissions during mining and processing, making copper clad steel a more eco-friendly alternative in many electrical and structural applications.

Choosing the Right Material: Copper Clad Steel vs Pure Copper

Choosing between copper clad steel and pure copper depends on your project's requirements for conductivity, strength, and cost. Copper clad steel offers enhanced tensile strength and corrosion resistance while maintaining reasonable electrical conductivity, making it ideal for grounding and transmission applications. Pure copper delivers superior conductivity and flexibility, which benefits high-performance electrical and electronic systems where minimal signal loss is critical.

Copper Clad Steel vs Pure Copper Infographic

libmatt.com

libmatt.com