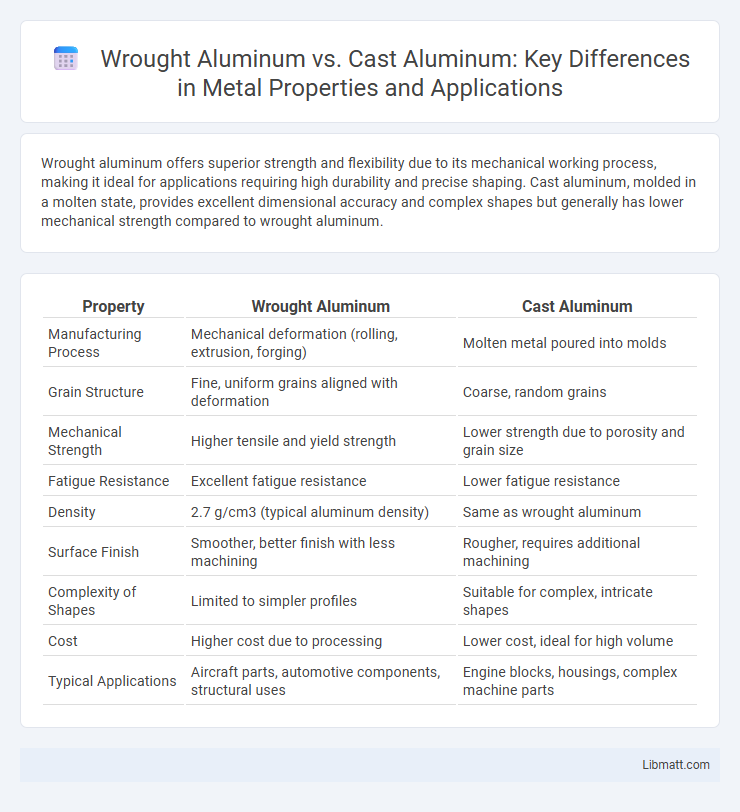

Wrought aluminum offers superior strength and flexibility due to its mechanical working process, making it ideal for applications requiring high durability and precise shaping. Cast aluminum, molded in a molten state, provides excellent dimensional accuracy and complex shapes but generally has lower mechanical strength compared to wrought aluminum.

Table of Comparison

| Property | Wrought Aluminum | Cast Aluminum |

|---|---|---|

| Manufacturing Process | Mechanical deformation (rolling, extrusion, forging) | Molten metal poured into molds |

| Grain Structure | Fine, uniform grains aligned with deformation | Coarse, random grains |

| Mechanical Strength | Higher tensile and yield strength | Lower strength due to porosity and grain size |

| Fatigue Resistance | Excellent fatigue resistance | Lower fatigue resistance |

| Density | 2.7 g/cm3 (typical aluminum density) | Same as wrought aluminum |

| Surface Finish | Smoother, better finish with less machining | Rougher, requires additional machining |

| Complexity of Shapes | Limited to simpler profiles | Suitable for complex, intricate shapes |

| Cost | Higher cost due to processing | Lower cost, ideal for high volume |

| Typical Applications | Aircraft parts, automotive components, structural uses | Engine blocks, housings, complex machine parts |

Introduction to Wrought and Cast Aluminum

Wrought aluminum is created by mechanically working aluminum alloys through processes like rolling, extruding, or forging, resulting in a denser and stronger material with improved mechanical properties. Cast aluminum is produced by pouring molten aluminum into molds, allowing complex shapes and designs but often with lower strength and higher porosity compared to wrought aluminum. Your choice between wrought and cast aluminum depends on the specific strength requirements and design complexity of your project.

Defining Wrought Aluminum

Wrought aluminum is aluminum that has been mechanically worked through processes like rolling, forging, or extrusion, enhancing its strength and ductility compared to its cast counterpart. This method aligns the metal's grain structure, resulting in improved toughness and fatigue resistance, making it ideal for structural and high-stress applications. Understanding the properties of wrought aluminum can help you select the right material for projects requiring superior mechanical performance.

Understanding Cast Aluminum

Cast aluminum features a molten aluminum alloy poured into molds to create complex shapes with excellent dimensional accuracy and smooth surfaces. It offers high corrosion resistance and good thermal conductivity, making it ideal for automotive and machinery parts that require intricate designs. While cast aluminum provides good strength, its mechanical properties typically fall below those of wrought aluminum, which undergoes deformation processes to enhance material strength and grain structure.

Key Differences in Manufacturing Processes

Wrought aluminum is produced through mechanical deformation processes such as rolling, extruding, or forging, which align the metal's grain structure for enhanced strength and ductility. Cast aluminum is created by pouring molten aluminum into molds, allowing complex shapes to be formed but resulting in a coarser grain structure and potentially lower mechanical properties. The manufacturing process of wrought aluminum typically yields improved fatigue resistance and uniformity compared to the more porous and less dense cast aluminum.

Mechanical Properties Comparison

Wrought aluminum exhibits higher tensile strength and improved fatigue resistance compared to cast aluminum due to its refined grain structure achieved through mechanical working processes. Cast aluminum, while offering excellent castability and complex shapes, generally displays lower ductility and reduced impact strength because of microscopic porosity inherent in casting. These mechanical properties make wrought aluminum more suitable for high-stress applications like aerospace and automotive components, whereas cast aluminum is often preferred for lightweight, intricate designs with moderate load requirements.

Typical Applications of Wrought Aluminum

Wrought aluminum is commonly used in aerospace components, automotive parts, and structural frameworks due to its superior strength, ductility, and fatigue resistance compared to cast aluminum. Its ability to be easily formed and machined makes it ideal for manufacturing aircraft skins, automotive panels, and industrial equipment. Wrought aluminum alloys are preferred for applications requiring precise mechanical properties and enhanced durability under dynamic loads.

Common Uses for Cast Aluminum

Cast aluminum is commonly used in manufacturing automotive engine blocks, cookware, and industrial machinery due to its excellent castability and ability to form complex shapes. Its superior vibration damping and corrosion resistance make it ideal for aerospace components and marine equipment. You will find cast aluminum essential in applications where lightweight, durability, and intricate design are critical.

Strengths and Weaknesses of Each Type

Wrought aluminum exhibits superior strength and ductility due to its refined grain structure from mechanical working, making it ideal for load-bearing applications requiring high toughness and fatigue resistance. Cast aluminum offers excellent design flexibility and corrosion resistance but tends to have lower tensile strength and is more prone to porosity and brittleness due to solidification defects. Selecting between wrought and cast aluminum depends on the specific mechanical performance needs and complexity of the component design.

Cost and Availability Considerations

Wrought aluminum typically features higher production costs due to extensive mechanical working processes but offers consistent quality and strength, making it widely available in standard sizes and forms for various applications. Cast aluminum is generally more cost-effective to produce because it involves pouring molten metal into molds, allowing complex shapes to be made with less machining, though availability can be limited by mold design and production volume. Manufacturers often choose cast aluminum for cost-sensitive projects requiring intricate geometries, while wrought aluminum suits applications demanding superior mechanical properties and standardized supply.

Choosing the Right Aluminum for Your Project

Wrought aluminum offers superior strength, ductility, and corrosion resistance, making it ideal for applications requiring durability and extreme shaping, such as aerospace or structural components. Cast aluminum provides excellent fluidity and design flexibility, suitable for complex shapes and lightweight parts like automotive engine blocks or housings. Understanding your project's load, form, and corrosion needs will help you decide whether wrought or cast aluminum best aligns with your performance and manufacturing requirements.

wrought aluminum vs cast aluminum Infographic

libmatt.com

libmatt.com