Open-die forging involves shaping metal between flat or simple contoured dies, allowing more flexibility in forming large and custom parts with minimal die cost, while closed-die forging uses precision-machined dies that enclose the metal completely, producing complex shapes with tighter tolerances and superior surface finish. Your choice depends on factors like production volume, part complexity, and mechanical property requirements.

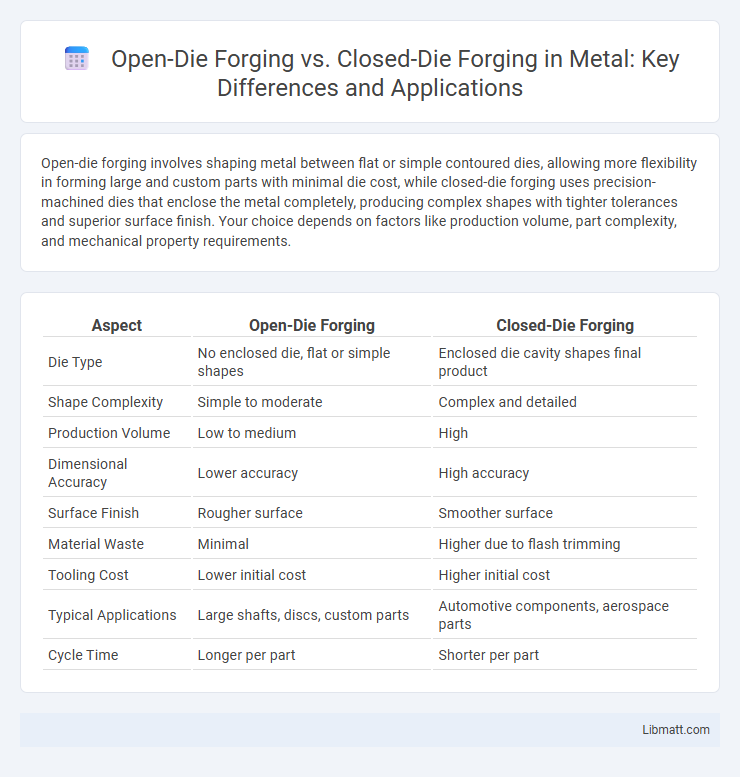

Table of Comparison

| Aspect | Open-Die Forging | Closed-Die Forging |

|---|---|---|

| Die Type | No enclosed die, flat or simple shapes | Enclosed die cavity shapes final product |

| Shape Complexity | Simple to moderate | Complex and detailed |

| Production Volume | Low to medium | High |

| Dimensional Accuracy | Lower accuracy | High accuracy |

| Surface Finish | Rougher surface | Smoother surface |

| Material Waste | Minimal | Higher due to flash trimming |

| Tooling Cost | Lower initial cost | Higher initial cost |

| Typical Applications | Large shafts, discs, custom parts | Automotive components, aerospace parts |

| Cycle Time | Longer per part | Shorter per part |

Introduction to Forging Processes

Open-die forging involves deforming a workpiece between flat or simple-shaped dies, allowing metal to flow freely and creating large parts with lower precision. Closed-die forging uses shaped dies that enclose the workpiece, producing complex geometries with higher dimensional accuracy and minimal machining. Both processes enhance metal grain structure, improving mechanical properties such as strength and fatigue resistance.

What is Open-Die Forging?

Open-die forging is a metal forming process where the workpiece is compressed between two flat or simply shaped dies, allowing free flow of material except where it contacts the dies. This technique is commonly used for large, simple shapes requiring precise grain structure and improved mechanical properties, often seen in aerospace and heavy machinery components. Unlike closed-die forging, it does not enclose the metal, enabling more flexible shaping but less intricate detail.

What is Closed-Die Forging?

Closed-die forging, also known as impression-die forging, involves shaping metal between two precisely machined dies that contain a pre-designed cavity matching the desired final shape. This process produces highly accurate and complex components with excellent mechanical properties and minimal material waste due to the confined metal flow. It is widely used in industries such as automotive, aerospace, and heavy machinery where strength, durability, and precision are critical.

Key Differences Between Open-Die and Closed-Die Forging

Open-die forging involves deforming a heated metal workpiece between flat or simple-shaped dies without fully enclosing it, allowing for greater flexibility and suitability for large, custom, or simple-shaped components. Closed-die forging, also known as impression-die forging, uses precisely shaped dies that encase the workpiece, producing complex, near-net-shape parts with excellent dimensional accuracy and surface finish. The key differences include the extent of die contact, precision of final shape, production speed, and application scope, with open-die ideal for low-volume, large parts and closed-die preferred for high-volume, intricately detailed components.

Material Suitability and Applications

Open-die forging is ideal for producing large, simple shapes from materials like aluminum, copper, and carbon steel, suited for heavy industry components such as shafts and discs. Closed-die forging excels with high-strength alloys and complex geometries, making it perfect for aerospace parts, automotive components, and precision tools. Your choice depends on material properties and application requirements, with open-die offering flexibility for larger pieces and closed-die providing detailed accuracy for smaller, intricate parts.

Strength and Mechanical Properties Comparison

Open-die forging typically produces components with superior strength and mechanical properties due to its ability to reduce internal porosity and refine grain structure through extensive deformation. Closed-die forging offers precise dimensional control but may induce higher internal stresses, potentially affecting toughness compared to open-die counterparts. Your choice should consider the required mechanical performance and strength criteria, as open-die forging is often preferred for critical structural components requiring enhanced durability.

Cost Considerations: Open-Die vs Closed-Die

Open-die forging typically incurs lower initial tooling costs compared to closed-die forging, making it more cost-effective for small production runs or large, simple parts. Closed-die forging involves higher upfront expenses due to complex die manufacturing but offers greater cost efficiency in high-volume production through reduced material waste and faster cycle times. Your choice depends on balancing these cost factors against production scale and part complexity.

Precision and Tolerance Capabilities

Closed-die forging offers superior precision and tighter tolerance capabilities compared to open-die forging, making it ideal for producing complex shapes with exact dimensions. Open-die forging provides greater flexibility but typically results in broader tolerances and less intricate detailing. For applications requiring high accuracy and repeatability, your choice should lean toward closed-die forging to meet stringent dimensional specifications.

Common Industries and Use Cases

Open-die forging is widely used in industries requiring large, simple shapes such as aerospace, shipbuilding, and heavy equipment manufacturing, where components like shafts, cylinders, and rings are produced. Closed-die forging finds applications in automotive, defense, and tool manufacturing industries, ideal for complex, high-strength parts such as gears, crankshafts, and connecting rods. Both processes optimize mechanical properties, with open-die forging suited for custom, low-volume orders and closed-die forging for high-volume, precision components.

Choosing the Right Forging Method

Choosing the right forging method depends on part complexity, production volume, and material properties; open-die forging is ideal for large, simple shapes requiring excellent mechanical properties, while closed-die forging suits high-volume production of intricate, precise components. Open-die forging offers greater flexibility and lower tooling costs but less geometric precision compared to closed-die forging, which provides repeatability and superior surface finish. Evaluating design tolerances, cost constraints, and mechanical performance requirements ensures optimal forging process selection.

Open-die forging vs closed-die forging Infographic

libmatt.com

libmatt.com