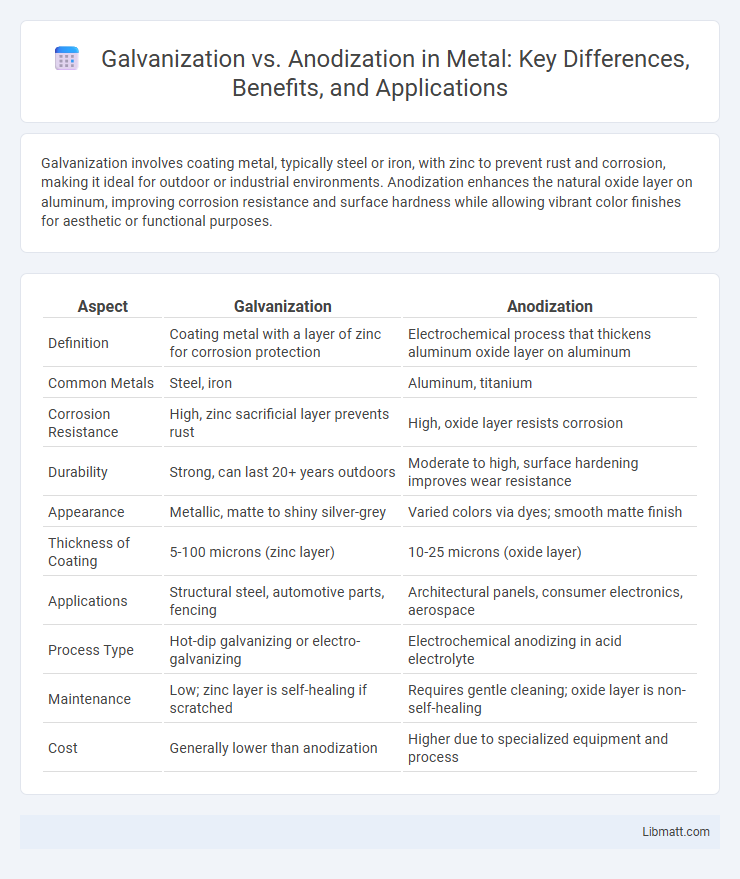

Galvanization involves coating metal, typically steel or iron, with zinc to prevent rust and corrosion, making it ideal for outdoor or industrial environments. Anodization enhances the natural oxide layer on aluminum, improving corrosion resistance and surface hardness while allowing vibrant color finishes for aesthetic or functional purposes.

Table of Comparison

| Aspect | Galvanization | Anodization |

|---|---|---|

| Definition | Coating metal with a layer of zinc for corrosion protection | Electrochemical process that thickens aluminum oxide layer on aluminum |

| Common Metals | Steel, iron | Aluminum, titanium |

| Corrosion Resistance | High, zinc sacrificial layer prevents rust | High, oxide layer resists corrosion |

| Durability | Strong, can last 20+ years outdoors | Moderate to high, surface hardening improves wear resistance |

| Appearance | Metallic, matte to shiny silver-grey | Varied colors via dyes; smooth matte finish |

| Thickness of Coating | 5-100 microns (zinc layer) | 10-25 microns (oxide layer) |

| Applications | Structural steel, automotive parts, fencing | Architectural panels, consumer electronics, aerospace |

| Process Type | Hot-dip galvanizing or electro-galvanizing | Electrochemical anodizing in acid electrolyte |

| Maintenance | Low; zinc layer is self-healing if scratched | Requires gentle cleaning; oxide layer is non-self-healing |

| Cost | Generally lower than anodization | Higher due to specialized equipment and process |

Introduction to Surface Treatments

Surface treatments like galvanization and anodization enhance metal durability by improving corrosion resistance and wear properties. Galvanization involves coating steel or iron with a layer of zinc to protect against rust, commonly used in construction and automotive industries. Anodization, primarily applied to aluminum, creates a durable oxide layer by electrochemical oxidation, improving surface hardness and aesthetic qualities.

What is Galvanization?

Galvanization is a metal coating process that involves applying a protective layer of zinc to steel or iron to prevent rust and corrosion. The most common method is hot-dip galvanizing, where the metal is submerged in molten zinc, creating a durable, corrosion-resistant barrier. This process significantly extends the lifespan of metal structures by providing sacrificial protection against environmental damage.

What is Anodization?

Anodization is an electrochemical process that enhances the natural oxide layer on metal surfaces, primarily aluminum, to improve corrosion resistance, durability, and aesthetic appeal. This treatment creates a thick, porous oxide layer that can also be dyed in various colors, providing both functional and decorative benefits. Unlike galvanization, which involves coating steel or iron with zinc, anodization chemically modifies the metal itself without adding an external layer.

Key Differences Between Galvanization and Anodization

Galvanization involves coating steel or iron with a layer of zinc to prevent corrosion, while anodization enhances the natural oxide layer on aluminum to increase durability and corrosion resistance. Galvanization provides sacrificial protection by corroding the zinc layer first, whereas anodization creates a harder surface directly on the metal. Key differences include the metals treated, protective mechanisms, and typical applications, with galvanization common in structural steel and anodization used in aerospace and consumer electronics for aluminum parts.

Materials Suitable for Galvanization vs Anodization

Galvanization is primarily suitable for ferrous metals such as steel and iron due to its zinc coating that provides corrosion resistance. Anodization is ideal for non-ferrous metals like aluminum, titanium, and magnesium, enhancing their oxide layer for durability and aesthetic appeal. Selecting between galvanization and anodization depends on the base metal's composition and the desired protective properties.

Process Overview: Galvanization

Galvanization involves coating metal, typically steel or iron, with a protective layer of zinc to prevent corrosion and rust. The most common method is hot-dip galvanizing, where the metal is submerged in molten zinc, forming a durable, corrosion-resistant alloy on the surface. This process extends the lifespan of metal structures by providing a sacrificial barrier that protects the underlying metal from environmental damage.

Process Overview: Anodization

Anodization is an electrochemical process that enhances the natural oxide layer on metals such as aluminum, increasing corrosion resistance, surface hardness, and aesthetic appeal. This process involves submerging the metal in an acid electrolyte bath while applying an electric current, which thickens the oxide layer through controlled oxidation. Anodized coatings are porous and can be dyed for color customization, offering both functional and decorative benefits unmatched by galvanization.

Advantages and Disadvantages

Galvanization provides superior corrosion resistance by coating metals like steel with a layer of zinc, making it highly effective for outdoor and industrial applications, but it can add weight and may peel over time. Anodization enhances aluminum's natural oxide layer, increasing durability and resistance to wear and corrosion while allowing for vibrant color finishes, though it only works on aluminum and can be more costly. Your material choice should consider these trade-offs based on environment, budget, and desired aesthetics.

Typical Applications and Industries

Galvanization is widely used in construction, automotive, and utility industries for corrosion protection of steel structures, fences, and electrical towers. Anodization is common in aerospace, electronics, and consumer goods, enhancing aluminum parts with improved durability and aesthetic appeal. Your choice depends on whether you need corrosion resistance for steel or surface finishing and color options for aluminum components.

Choosing the Right Method for Your Needs

Galvanization involves coating metal with a protective layer of zinc to prevent rust, making it ideal for outdoor or industrial applications requiring corrosion resistance. Anodization enhances aluminum surfaces by forming a durable oxide layer that improves wear resistance and aesthetic appeal, suitable for decorative or lightweight components. Evaluating factors such as environmental exposure, material type, and desired finish will help you choose the right method for your specific needs.

Galvanization vs anodization Infographic

libmatt.com

libmatt.com