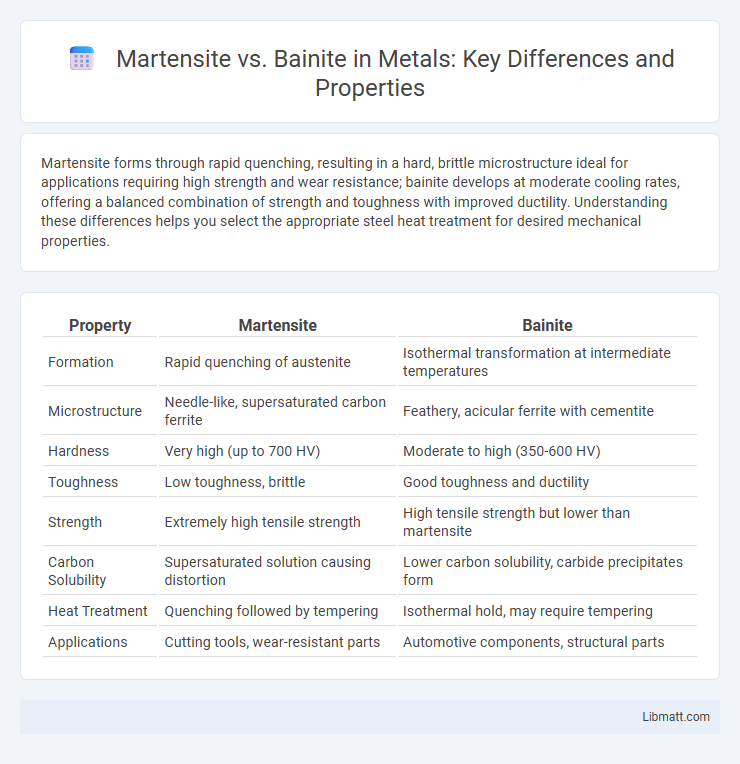

Martensite forms through rapid quenching, resulting in a hard, brittle microstructure ideal for applications requiring high strength and wear resistance; bainite develops at moderate cooling rates, offering a balanced combination of strength and toughness with improved ductility. Understanding these differences helps you select the appropriate steel heat treatment for desired mechanical properties.

Table of Comparison

| Property | Martensite | Bainite |

|---|---|---|

| Formation | Rapid quenching of austenite | Isothermal transformation at intermediate temperatures |

| Microstructure | Needle-like, supersaturated carbon ferrite | Feathery, acicular ferrite with cementite |

| Hardness | Very high (up to 700 HV) | Moderate to high (350-600 HV) |

| Toughness | Low toughness, brittle | Good toughness and ductility |

| Strength | Extremely high tensile strength | High tensile strength but lower than martensite |

| Carbon Solubility | Supersaturated solution causing distortion | Lower carbon solubility, carbide precipitates form |

| Heat Treatment | Quenching followed by tempering | Isothermal hold, may require tempering |

| Applications | Cutting tools, wear-resistant parts | Automotive components, structural parts |

Introduction to Martensite and Bainite

Martensite is a hard, brittle microstructure formed in steel by rapid quenching from the austenite phase, characterized by a body-centered tetragonal (BCT) crystal structure. Bainite develops at moderate cooling rates, producing a fine microstructure composed of ferrite and cementite that balances strength and toughness. Understanding these distinct phases helps optimize Your steel's mechanical properties for various industrial applications.

Microstructural Differences

Martensite exhibits a highly strained, body-centered tetragonal microstructure formed by rapid quenching, characterized by needle-like or lath-shaped features that increase hardness but reduce ductility. Bainite, in contrast, develops through controlled cooling at intermediate temperatures and consists of a fine mixture of ferrite and cementite, providing a balance between strength and toughness. Your choice between these phases influences mechanical properties significantly due to their distinct microstructural characteristics.

Formation Mechanisms

Martensite forms through a diffusionless, shear-dominant transformation where austenite rapidly cools, causing a lattice distortion that traps carbon atoms in a body-centered tetragonal structure. Bainite develops via a diffusion-controlled process at intermediate cooling rates, where carbon atoms diffuse out of the transforming phase to form a fine microstructure of ferrite and cementite or carbides. The distinct transformation kinetics and atomic movements define their unique hardness, toughness, and mechanical properties in steel metallurgy.

Temperature Ranges of Transformation

Martensite forms rapidly at temperatures typically below 250degC through a diffusionless transformation, resulting in a hard and brittle microstructure. Bainite develops at intermediate temperatures between approximately 250degC and 550degC, where carbon diffusion allows for a combination of strength and toughness. Understanding these temperature ranges guides your heat treatment process to achieve the desired balance of mechanical properties in steel.

Mechanical Properties Comparison

Martensite exhibits exceptional hardness and high tensile strength, making it ideal for wear-resistant applications, but it tends to be brittle with limited toughness. Bainite provides a balanced combination of strength and ductility, offering improved toughness and fatigue resistance compared to martensite. Your choice between martensite and bainite should consider the required mechanical properties, as bainite enhances impact resistance while martensite maximizes hardness.

Hardness and Toughness

Martensite exhibits high hardness due to its supersaturated carbon structure, making it ideal for applications requiring wear resistance. Bainite offers a balanced combination of moderate hardness and superior toughness, enhancing impact resistance without brittleness. You can select bainite when toughness is critical, whereas martensite suits uses demanding maximum hardness.

Applications in Industry

Martensite's high hardness and strength make it ideal for cutting tools, wear-resistant parts, and structural components in automotive and aerospace industries. Bainite offers a balanced combination of toughness and strength, commonly used in railway tracks, gears, and heavy machinery requiring durability and resistance to impact. Both microstructures are vital in tailoring mechanical properties for specific industrial applications through heat treatment processes.

Advantages and Disadvantages

Martensite offers exceptional hardness and strength due to its highly strained crystal structure but tends to be brittle and less ductile, making it prone to cracking under impact. Bainite provides a balanced combination of strength and toughness with improved ductility, resulting from its fine microstructure formed at intermediate cooling rates, though it generally has lower hardness compared to martensite. Your choice between martensite and bainite should consider the specific application requirements for wear resistance versus toughness and the potential need for post-treatment to optimize mechanical properties.

Factors Influencing Formation

The formation of martensite and bainite in steel is primarily influenced by cooling rate and temperature. Rapid quenching promotes martensite formation by suppressing diffusion, while slower cooling within the bainitic temperature range enables bainite to form through diffusion-controlled transformations. Alloy composition, such as carbon and alloying elements like manganese and chromium, also affects transformation kinetics and stability, determining the resulting microstructure.

Summary and Conclusion

Martensite offers maximum hardness and strength due to its distorted lattice structure formed by rapid quenching, while bainite provides a better balance of strength and toughness with its finer microstructure developed at intermediate cooling rates. Your choice between martensite and bainite depends on the required mechanical properties and application conditions, such as wear resistance or impact toughness. Understanding the differences in phase transformation kinetics and resulting microstructures ensures optimized material performance for specific engineering needs.

Martensite vs Bainite Infographic

libmatt.com

libmatt.com