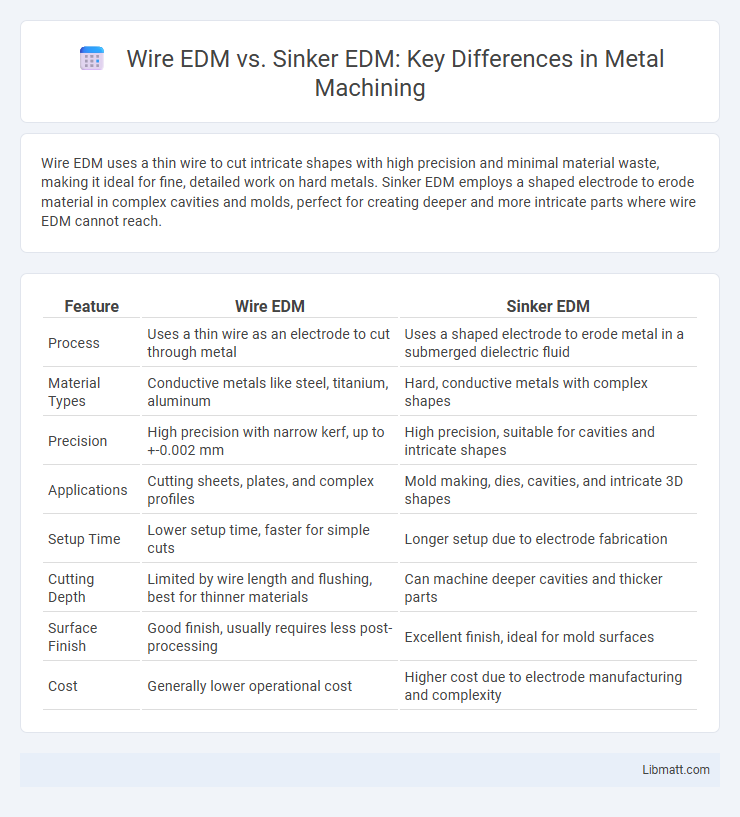

Wire EDM uses a thin wire to cut intricate shapes with high precision and minimal material waste, making it ideal for fine, detailed work on hard metals. Sinker EDM employs a shaped electrode to erode material in complex cavities and molds, perfect for creating deeper and more intricate parts where wire EDM cannot reach.

Table of Comparison

| Feature | Wire EDM | Sinker EDM |

|---|---|---|

| Process | Uses a thin wire as an electrode to cut through metal | Uses a shaped electrode to erode metal in a submerged dielectric fluid |

| Material Types | Conductive metals like steel, titanium, aluminum | Hard, conductive metals with complex shapes |

| Precision | High precision with narrow kerf, up to +-0.002 mm | High precision, suitable for cavities and intricate shapes |

| Applications | Cutting sheets, plates, and complex profiles | Mold making, dies, cavities, and intricate 3D shapes |

| Setup Time | Lower setup time, faster for simple cuts | Longer setup due to electrode fabrication |

| Cutting Depth | Limited by wire length and flushing, best for thinner materials | Can machine deeper cavities and thicker parts |

| Surface Finish | Good finish, usually requires less post-processing | Excellent finish, ideal for mold surfaces |

| Cost | Generally lower operational cost | Higher cost due to electrode manufacturing and complexity |

Introduction to Wire EDM and Sinker EDM

Wire EDM uses a thin, electrically charged wire to cut conductive materials with high precision, ideal for creating intricate shapes and fine details. Sinker EDM employs a specially shaped electrode to erode material in a submerged dielectric fluid, best suited for machining complex cavities and deep profiles. Understanding the differences between wire EDM and sinker EDM helps you select the optimal process for your detailed manufacturing needs.

How Wire EDM Works

Wire EDM works by using a thin, electrically charged wire as an electrode to cut through metal with extreme precision. The wire moves along programmed paths, creating a series of sparks that erode the material, allowing for complex shapes and fine details. High-speed flushing removes debris during the process, maintaining accuracy and surface finish quality.

How Sinker EDM Works

Sinker EDM, also known as ram EDM, works by submerging an electrode and a workpiece in a dielectric fluid and generating controlled electrical discharges that erode the material to create intricate shapes. The electrode, typically made of graphite or copper, is shaped precisely to form the cavity in the workpiece through a series of rapid sparks that vaporize metal particles without physical contact. This process enables the machining of complex geometries and hardened materials with high precision and minimal mechanical stress.

Key Differences Between Wire EDM and Sinker EDM

Wire EDM uses a continuously moving thin wire as the electrode, allowing precise cutting of complex shapes in hard metals with minimal waste, while Sinker EDM employs a shaped electrode to erode material in volumetric cavities. Wire EDM excels in creating intricate 2D contours and fine details with high accuracy, whereas Sinker EDM is ideal for producing 3D cavities and molds with complex geometries. The selection between Wire EDM and Sinker EDM depends on part design, required precision, and machining complexity.

Applications of Wire EDM

Wire EDM excels in precision cutting of complex shapes and hard metals such as titanium and Inconel, commonly used in aerospace, automotive, and medical device manufacturing. This process is ideal for producing intricate components like turbine blades, molds, and dies with tight tolerances and fine surface finishes. Wire EDM's ability to cut through conductive materials with minimal thermal distortion ensures high-quality results in tooling and micro-machining applications.

Applications of Sinker EDM

Sinker EDM excels in producing complex cavities, molds, and intricate internal geometries that are difficult to machine using traditional methods. Its precise control over electrode shape allows for detailed features in dies and aerospace components, making it ideal for manufacturing parts with deep recesses and irregular contours. Your manufacturing process benefits from Sinker EDM when high precision in hard metals and detailed 3D shapes are required.

Advantages of Wire EDM

Wire EDM offers precise cutting of complex shapes with a narrow kerf, resulting in minimal material waste and superior surface finishes. It excels in machining hard metals and intricate parts with tight tolerances, ensuring high accuracy and repeatability. Your manufacturing process benefits from faster production speeds and reduced secondary operations compared to Sinker EDM.

Advantages of Sinker EDM

Sinker EDM offers precise machining for complex, intricate shapes and deep cavities that are challenging to achieve with Wire EDM. Its ability to use custom-shaped electrodes allows for detailed surface finishes and accurate contours on hard materials. Your manufacturing process benefits from Sinker EDM's versatility in creating molds, dies, and intricate parts with high precision and reduced post-processing.

Choosing the Right EDM Process

Choosing the right EDM process depends on your specific machining needs, material type, and desired precision. Wire EDM excels in creating intricate, complex shapes with tight tolerances on hard metals, while Sinker EDM is ideal for detailed cavity work and features in conductive materials. Your decision should consider factors such as part geometry, surface finish requirements, and production volume to optimize efficiency and accuracy.

Conclusion: Wire EDM vs Sinker EDM

Wire EDM offers superior precision and cleaner cuts for intricate parts, making it ideal for complex geometries and thin materials. Sinker EDM excels in producing deep cavities and detailed 3D shapes in hard metals, providing excellent surface finishes for molds and dies. Your choice depends on the specific application requirements, geometry complexity, and material thickness for optimal manufacturing efficiency.

Wire EDM vs Sinker EDM Infographic

libmatt.com

libmatt.com