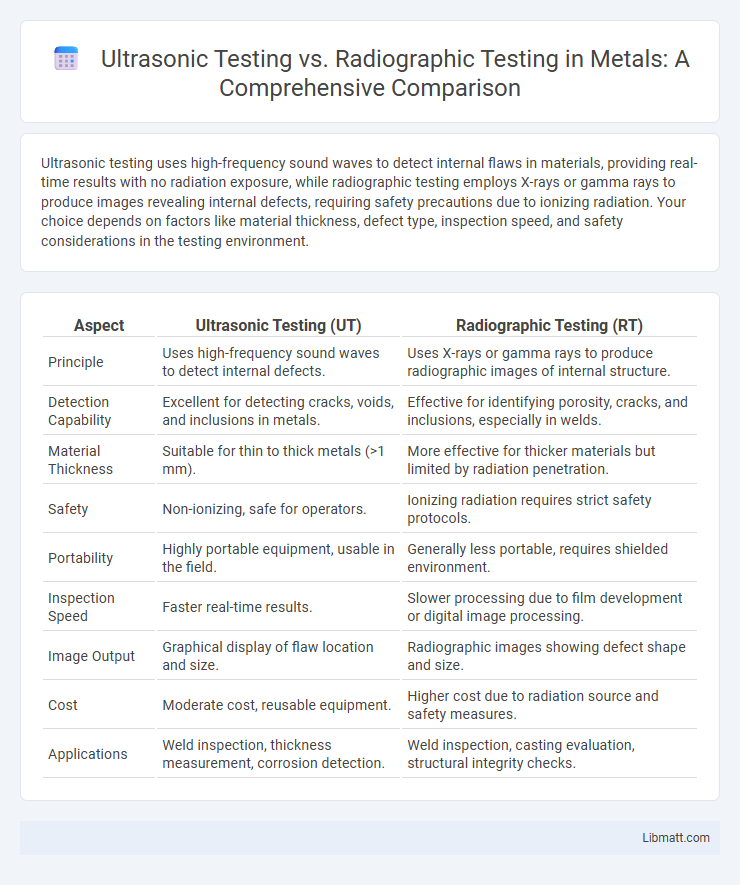

Ultrasonic testing uses high-frequency sound waves to detect internal flaws in materials, providing real-time results with no radiation exposure, while radiographic testing employs X-rays or gamma rays to produce images revealing internal defects, requiring safety precautions due to ionizing radiation. Your choice depends on factors like material thickness, defect type, inspection speed, and safety considerations in the testing environment.

Table of Comparison

| Aspect | Ultrasonic Testing (UT) | Radiographic Testing (RT) |

|---|---|---|

| Principle | Uses high-frequency sound waves to detect internal defects. | Uses X-rays or gamma rays to produce radiographic images of internal structure. |

| Detection Capability | Excellent for detecting cracks, voids, and inclusions in metals. | Effective for identifying porosity, cracks, and inclusions, especially in welds. |

| Material Thickness | Suitable for thin to thick metals (>1 mm). | More effective for thicker materials but limited by radiation penetration. |

| Safety | Non-ionizing, safe for operators. | Ionizing radiation requires strict safety protocols. |

| Portability | Highly portable equipment, usable in the field. | Generally less portable, requires shielded environment. |

| Inspection Speed | Faster real-time results. | Slower processing due to film development or digital image processing. |

| Image Output | Graphical display of flaw location and size. | Radiographic images showing defect shape and size. |

| Cost | Moderate cost, reusable equipment. | Higher cost due to radiation source and safety measures. |

| Applications | Weld inspection, thickness measurement, corrosion detection. | Weld inspection, casting evaluation, structural integrity checks. |

Introduction to Ultrasonic and Radiographic Testing

Ultrasonic Testing (UT) uses high-frequency sound waves to detect internal flaws and measure material thickness, providing immediate and precise results without harmful radiation. Radiographic Testing (RT) employs X-rays or gamma rays to produce detailed images of internal structures, revealing defects such as cracks, voids, or inclusions within metals and welds. Your choice between UT and RT depends on factors like inspection speed, material type, safety considerations, and the level of detail required for accurate defect characterization.

Principles of Ultrasonic Testing

Ultrasonic testing operates by emitting high-frequency sound waves into materials and analyzing the reflected signals to detect internal flaws or discontinuities. The velocity and attenuation of these sound waves vary depending on material density and the presence of defects, allowing precise flaw characterization. This non-destructive testing method offers advantages such as high sensitivity, depth penetration, and immediate results compared to radiographic testing.

Principles of Radiographic Testing

Radiographic testing (RT) utilizes X-rays or gamma rays to penetrate materials and produce images on photographic film or digital detectors, revealing internal flaws like cracks or voids. The intensity of radiation passing through the material varies according to density and thickness, enabling defect visualization based on differential absorption. RT is highly effective for inspecting welds, castings, and composite materials where precise internal structural analysis is critical.

Key Differences Between Ultrasonic and Radiographic Testing

Ultrasonic testing uses high-frequency sound waves to detect internal flaws and measure material thickness, providing immediate results with high sensitivity for detecting small cracks. Radiographic testing employs X-rays or gamma rays to create images of internal structures, offering detailed visualization of volumetric defects but requires more safety precautions due to radiation exposure. Ultrasonic testing is more portable and faster, while radiographic testing delivers permanent records and better detection of porosity and inclusions in thicker materials.

Advantages of Ultrasonic Testing

Ultrasonic testing offers superior sensitivity in detecting internal flaws and thickness measurements without exposing operators to ionizing radiation, making it safer compared to radiographic testing. It provides immediate results and can inspect complex geometries and layered materials with high precision. The portability and cost-effectiveness of ultrasonic equipment further enhance its suitability for on-site and frequent inspections.

Advantages of Radiographic Testing

Radiographic testing offers the significant advantage of providing a permanent visual record of the internal structure, making it easier to review and compare over time. It reveals detailed images of defects such as cracks, voids, and inclusions within welds and castings, which helps ensure the integrity and safety of critical components. Your inspection process benefits from its ability to test complex geometries and thick materials without requiring direct surface access.

Limitations of Ultrasonic Testing

Ultrasonic testing faces limitations such as difficulty detecting flaws near the surface or complex geometries where sound waves may scatter. Its effectiveness can be reduced by material properties like grain size and thickness, which affect wave propagation. You may need to complement it with radiographic testing when detailed internal imaging or flaw characterization is required.

Limitations of Radiographic Testing

Radiographic testing (RT) has limitations including lower sensitivity to planar defects compared to ultrasonic testing (UT), and safety concerns due to the use of ionizing radiation requiring strict regulatory controls. RT struggles with detecting defects in thick or dense materials because of radiation attenuation, and interpretation of radiographs can be subjective and time-consuming. Access limitations also arise since RT requires opposite sides for radiation penetration, whereas UT can be conducted from a single surface.

Applications: When to Use Ultrasonic vs Radiographic Testing

Ultrasonic testing is ideal for detecting internal flaws and measuring thickness in metals, composites, and welds, especially in aerospace, automotive, and manufacturing industries where precise flaw characterization is critical. Radiographic testing excels in inspecting weld integrity, casting defects, and structural components by producing detailed images of internal features, widely used in oil and gas, power plants, and construction sectors. Ultrasonic testing offers real-time results and portability for field inspections, while radiographic testing is preferred for complex geometries and when visual records of defects are required for regulatory compliance.

Selecting the Right Non-Destructive Testing Method

Ultrasonic testing (UT) excels in detecting internal flaws with high precision using high-frequency sound waves, making it ideal for thick materials and complex geometries. Radiographic testing (RT) provides detailed imaging through X-rays or gamma rays, useful for identifying volumetric defects in welds and castings but requires strict safety measures and longer processing times. Your choice between UT and RT depends on factors like material type, defect sensitivity, inspection speed, and accessibility, ensuring optimal non-destructive testing outcomes.

ultrasonic testing vs radiographic testing Infographic

libmatt.com

libmatt.com