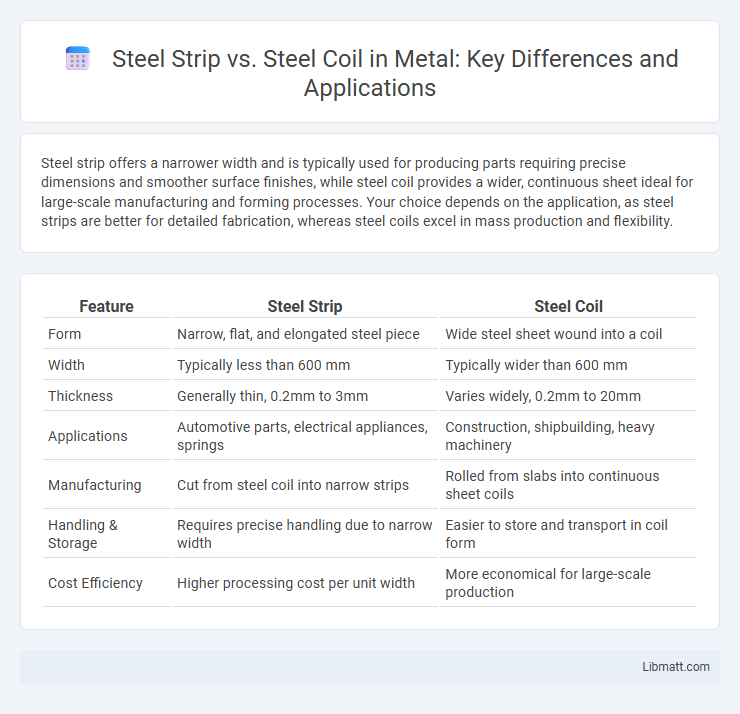

Steel strip offers a narrower width and is typically used for producing parts requiring precise dimensions and smoother surface finishes, while steel coil provides a wider, continuous sheet ideal for large-scale manufacturing and forming processes. Your choice depends on the application, as steel strips are better for detailed fabrication, whereas steel coils excel in mass production and flexibility.

Table of Comparison

| Feature | Steel Strip | Steel Coil |

|---|---|---|

| Form | Narrow, flat, and elongated steel piece | Wide steel sheet wound into a coil |

| Width | Typically less than 600 mm | Typically wider than 600 mm |

| Thickness | Generally thin, 0.2mm to 3mm | Varies widely, 0.2mm to 20mm |

| Applications | Automotive parts, electrical appliances, springs | Construction, shipbuilding, heavy machinery |

| Manufacturing | Cut from steel coil into narrow strips | Rolled from slabs into continuous sheet coils |

| Handling & Storage | Requires precise handling due to narrow width | Easier to store and transport in coil form |

| Cost Efficiency | Higher processing cost per unit width | More economical for large-scale production |

Introduction to Steel Strip and Steel Coil

Steel strip is a flat, narrow piece of metal typically cut from steel coils, with precise width and thickness ideal for manufacturing and construction applications. Steel coils are large rolls of steel sheet produced by continuous rolling processes, offering versatility for various industrial uses. Your choice between steel strip and steel coil depends on specific project requirements such as size, processing needs, and application.

Definitions: What is Steel Strip?

Steel strip is a flat, narrow steel product that is typically produced by slitting a steel coil into thinner sections with consistent thickness and width. Unlike steel coils, which are coiled for storage and transportation, steel strips are often used in applications requiring precise dimensions, such as automotive parts, appliances, and construction materials. Your choice between steel strip and coil depends on the specific manufacturing process and end-use requirements.

Definitions: What is Steel Coil?

Steel coil is a flat steel product formed by rolling hot or cold steel sheets into a coiled shape for efficient storage and transportation. It offers versatility in manufacturing processes such as stamping, cutting, and forming, making it essential in automotive, construction, and appliance industries. Understanding steel coil properties helps you select the right material for precise structural or functional applications.

Manufacturing Processes of Steel Strip vs Steel Coil

Steel strip is manufactured by cold rolling steel coils into thinner, flat sheets with precise thickness, ideal for applications requiring tight dimensional tolerances. Steel coil production involves hot rolling steel slabs into large, coiled rolls, which maintain flexibility for easier transport and storage. The main difference lies in the cold rolling process of steel strips that enhances surface finish and mechanical properties, whereas steel coils often undergo initial hot rolling and may be further processed into strips.

Key Differences Between Steel Strip and Steel Coil

Steel strip and steel coil differ primarily in shape and thickness; steel strip is a flat, narrow sheet with uniform thickness, while steel coil is wider and coiled for easy transport and storage. Steel strips are typically used in precision manufacturing requiring tight dimensional tolerances, whereas steel coils serve as raw material for various industrial processes, including cutting, stamping, and rolling. The manufacturing processes also vary, with steel strips often undergoing cold rolling for smoothness, while steel coils may be hot or cold rolled depending on intended use.

Common Applications of Steel Strip

Steel strips are widely used in automotive manufacturing for components such as body panels and chassis parts due to their uniform thickness and easy formability. They are essential in electrical appliances, providing durable, conductive material for motor laminations and transformers. In construction, steel strips serve as reinforcement in framing and as precision-cut elements in HVAC systems, benefiting from their high tensile strength and corrosion resistance.

Common Applications of Steel Coil

Steel coil is widely used in manufacturing automotive parts, construction materials, and household appliances due to its flexibility and ease of processing. The flat, continuous form of steel coil allows for efficient cutting, stamping, and shaping, making it ideal for producing roofing sheets, pipelines, and metal furniture. Your choice of steel coil ensures durability and precision in applications requiring consistent thickness and surface quality.

Advantages and Disadvantages of Steel Strip

Steel strip offers precise dimensional accuracy and smoother surface finishes compared to steel coil, making it ideal for applications requiring tight tolerances such as automotive parts and electronics. Its flat, narrow shape allows easier handling and processing in stamping, cutting, and forming operations, but it may be less versatile than steel coil, which can be uncoiled and cut into various sizes. You benefit from steel strip's enhanced quality and consistency, though it might come at a higher cost and with limited size adaptability compared to steel coil.

Advantages and Disadvantages of Steel Coil

Steel coil offers advantages such as ease of transport and storage due to its compact rolled form, and greater flexibility for use in continuous processing industries like automotive and construction. However, disadvantages include potential deformation during uncoiling, requiring specialized equipment, and susceptibility to surface damage or corrosion if not properly protected. Your choice between steel strip and steel coil depends on the specific application requirements, production processes, and handling capabilities.

How to Choose Between Steel Strip and Steel Coil

Selecting between steel strip and steel coil depends on the specific application requirements, such as the desired thickness, width, and end-use process. Steel strips offer precision and uniformity ideal for manufacturing components like springs and automotive parts, while steel coils provide bulk material suitable for large-scale fabrication and continuous processing in industries like construction and shipbuilding. Consider factors such as dimensional specifications, production volume, handling logistics, and cost-effectiveness to determine the most efficient form for your project.

Steel strip vs steel coil Infographic

libmatt.com

libmatt.com