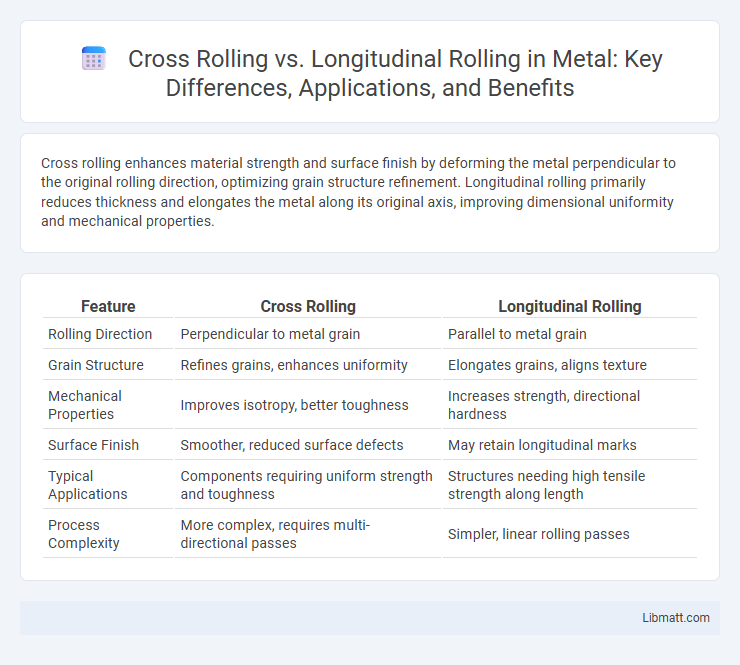

Cross rolling enhances material strength and surface finish by deforming the metal perpendicular to the original rolling direction, optimizing grain structure refinement. Longitudinal rolling primarily reduces thickness and elongates the metal along its original axis, improving dimensional uniformity and mechanical properties.

Table of Comparison

| Feature | Cross Rolling | Longitudinal Rolling |

|---|---|---|

| Rolling Direction | Perpendicular to metal grain | Parallel to metal grain |

| Grain Structure | Refines grains, enhances uniformity | Elongates grains, aligns texture |

| Mechanical Properties | Improves isotropy, better toughness | Increases strength, directional hardness |

| Surface Finish | Smoother, reduced surface defects | May retain longitudinal marks |

| Typical Applications | Components requiring uniform strength and toughness | Structures needing high tensile strength along length |

| Process Complexity | More complex, requires multi-directional passes | Simpler, linear rolling passes |

Introduction to Cross Rolling and Longitudinal Rolling

Cross rolling and longitudinal rolling are two fundamental metalworking processes that shape materials by passing them through rollers. Cross rolling involves rolling the material in multiple directions, producing uniform grain structure and enhanced mechanical properties, while longitudinal rolling primarily deforms the material along its length, offering efficient thickness reduction. Understanding these processes helps optimize your metal forming techniques for specific applications and performance requirements.

Fundamental Principles of Cross Rolling

Cross rolling involves deforming metal by applying forces in multiple directions, enhancing material properties like grain refinement and isotropy. Unlike longitudinal rolling, where deformation occurs primarily along the rolling direction, cross rolling redirects the flow of metal, promoting better mechanical strength. This technique optimizes the microstructure for applications requiring increased toughness and uniformity.

Core Concepts of Longitudinal Rolling

Longitudinal rolling involves compressing and elongating metal along its length using rollers that rotate parallel to the direction of metal flow, optimizing grain structure for enhanced strength and durability. This process is essential in producing uniform thickness and improving surface finish, making it ideal for manufacturing sheets, strips, and plates. Your understanding of this technique will help in selecting appropriate methods for metal forming based on precision and mechanical property requirements.

Key Differences Between Cross Rolling and Longitudinal Rolling

Cross rolling involves deforming metal perpendicular to its original grain direction, enhancing strength and surface finish by altering grain structure, while longitudinal rolling compresses metal parallel to the grain, promoting elongation and uniform mechanical properties. Cross rolling typically produces finer grain refinement and improved isotropy, whereas longitudinal rolling favors lengthwise dimension control and faster processing speeds. Understanding your desired metal characteristics helps determine the optimal rolling technique for manufacturing precision components.

Material Microstructure Effects in Cross Rolling

Cross rolling significantly refines the grain structure by altering the rolling direction between passes, leading to a more isotropic material microstructure. This process enhances mechanical properties such as tensile strength and toughness compared to longitudinal rolling, which tends to elongate grains and induce anisotropy. Your choice of cross rolling can improve material uniformity and resistance to cracking in critical applications.

Mechanical Property Variations in Longitudinal Rolling

Longitudinal rolling significantly enhances tensile strength and ductility along the rolling direction due to grain elongation and texture development. This process improves mechanical anisotropy, making the material stronger and more resistant to deformation in the rolling direction but potentially weaker transversely. Your components benefit from tailored mechanical properties where load-bearing requirements align with the rolling direction to maximize performance.

Applications and Industry Use Cases

Cross rolling is primarily used in manufacturing processes that require enhanced mechanical properties and dimensional accuracy in components such as shafts, gears, and automotive parts, benefiting industries like aerospace, automotive, and heavy machinery. Longitudinal rolling finds extensive applications in producing long products like rails, bars, and beams used in construction, shipbuilding, and infrastructure projects where uniform grain structure and strength along the length are critical. Both techniques optimize material flow and structural integrity but cater to distinct industrial needs based on the final product geometry and performance requirements.

Advantages and Limitations of Each Technique

Cross rolling enhances uniformity and refines grain structure by applying deformation in multiple directions, improving mechanical properties and reducing anisotropy, but it demands complex equipment and precise control, which can increase production costs. Longitudinal rolling offers a simpler setup and higher throughput by deforming metal along a single axis, suitable for producing long, consistent shapes, but it may result in directional weaknesses and less homogenous microstructures. Your choice between these techniques depends on balancing the need for mechanical performance and processing efficiency.

Selection Criteria: When to Choose Cross or Longitudinal Rolling

Selection criteria for choosing between cross rolling and longitudinal rolling primarily depend on the desired material properties and grain orientation. Cross rolling is preferred when enhanced isotropy, refined microstructure, and improved mechanical properties in multiple directions are required, especially for complex-shaped components. Longitudinal rolling is ideal for applications needing directional strength and uniform grain flow along the rolling direction, such as in structural beams or sheets where lengthwise tensile strength is critical.

Future Trends in Rolling Technologies

Future trends in rolling technologies emphasize the integration of cross rolling and longitudinal rolling to enhance material properties and manufacturing efficiency. Advanced automation and AI-driven monitoring systems optimize these processes for precision and reduced waste, providing Your production with greater consistency and lower costs. Innovations such as hybrid rolling techniques and adaptive control systems are poised to revolutionize metal forming by combining the strengths of both rolling methods.

Cross Rolling vs Longitudinal Rolling Infographic

libmatt.com

libmatt.com