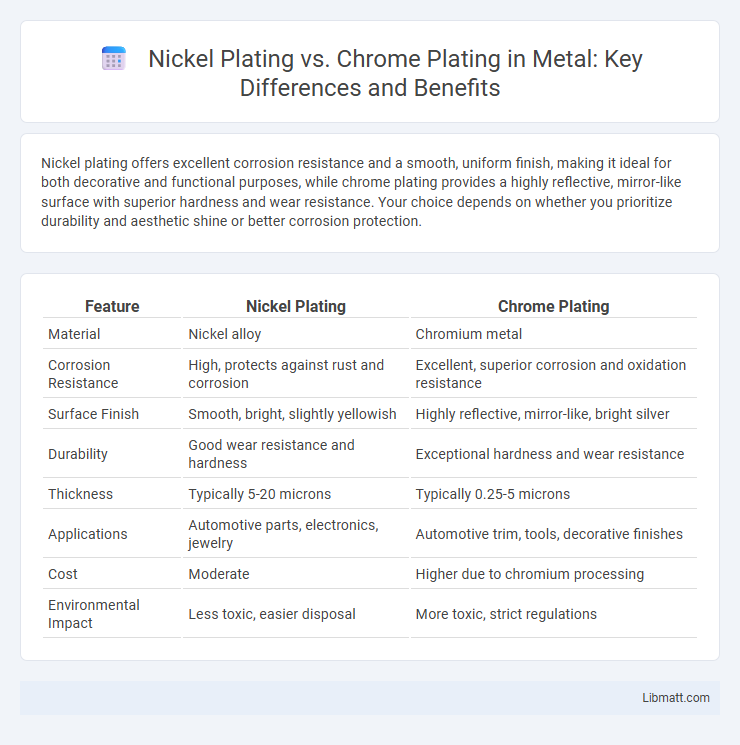

Nickel plating offers excellent corrosion resistance and a smooth, uniform finish, making it ideal for both decorative and functional purposes, while chrome plating provides a highly reflective, mirror-like surface with superior hardness and wear resistance. Your choice depends on whether you prioritize durability and aesthetic shine or better corrosion protection.

Table of Comparison

| Feature | Nickel Plating | Chrome Plating |

|---|---|---|

| Material | Nickel alloy | Chromium metal |

| Corrosion Resistance | High, protects against rust and corrosion | Excellent, superior corrosion and oxidation resistance |

| Surface Finish | Smooth, bright, slightly yellowish | Highly reflective, mirror-like, bright silver |

| Durability | Good wear resistance and hardness | Exceptional hardness and wear resistance |

| Thickness | Typically 5-20 microns | Typically 0.25-5 microns |

| Applications | Automotive parts, electronics, jewelry | Automotive trim, tools, decorative finishes |

| Cost | Moderate | Higher due to chromium processing |

| Environmental Impact | Less toxic, easier disposal | More toxic, strict regulations |

Introduction to Nickel and Chrome Plating

Nickel plating provides a durable, corrosion-resistant coating with excellent wear resistance, making it ideal for industrial applications where protection and longevity are crucial. Chrome plating offers a bright, reflective finish along with enhanced hardness and oxidation resistance, commonly used for aesthetic appeal and surface protection on automotive and decorative parts. Your choice between nickel and chrome plating depends on whether you prioritize durability and corrosion resistance or a shiny, polished appearance.

Overview of the Plating Processes

Nickel plating involves depositing a layer of nickel onto a metal substrate through electrochemical or electroless methods, providing corrosion resistance and enhanced surface hardness. Chrome plating applies a thin layer of chromium, typically via electroplating, known for its high gloss finish and superior wear resistance. Both processes enhance durability, but nickel plating offers better corrosion protection while chrome plating excels in aesthetic appeal and hardness.

Key Differences Between Nickel and Chrome Plating

Nickel plating offers excellent corrosion resistance and a smoother, more durable finish, making it ideal for applications requiring wear protection and enhanced adhesion for subsequent coatings. Chrome plating provides a highly reflective, mirror-like surface with superior hardness and scratch resistance, often used for decorative purposes and automotive trims. Your choice between nickel and chrome plating depends on whether durability and corrosion resistance or aesthetic shine and hardness are the primary requirements.

Performance and Durability Comparison

Nickel plating offers excellent corrosion resistance and provides a smoother, more uniform surface, making it highly durable for industrial applications requiring wear resistance. Chrome plating delivers superior hardness and a striking reflective finish, enhancing aesthetic appeal while protecting against scratches and environmental damage. Your choice between nickel and chrome plating should consider the need for durability, surface finish, and environmental exposure to optimize performance.

Aesthetic Appeal: Nickel vs Chrome Finish

Nickel plating offers a warm, glossy finish with a slightly yellowish tint, enhancing vintage or classic designs, while chrome plating provides a bright, mirror-like, and highly reflective surface that suits modern and high-gloss aesthetics. Nickel's durability resists corrosion and tarnish, maintaining its luster over time, whereas chrome excels in scratch resistance and sharp, clean edges. Both finishes contribute distinct visual appeal, with nickel favoring subtle elegance and chrome delivering striking brilliance.

Applications and Common Uses

Nickel plating offers excellent corrosion resistance and wear protection, making it ideal for automotive parts, aerospace components, and electronic connectors. Chrome plating is commonly used for decorative purposes and high-gloss finishes on faucets, motorcycle parts, and bathroom fixtures due to its reflective surface and hardness. Your choice between nickel and chrome plating should consider whether durability or aesthetic appeal is the priority for your specific application.

Cost Analysis of Nickel and Chrome Plating

Nickel plating generally costs less than chrome plating due to lower material and processing expenses, making it a budget-friendly choice for corrosion resistance and decorative finishes. Chrome plating involves higher costs because of the complex electroplating process and use of hazardous chemicals, which require stringent handling and disposal measures. Your decision between nickel and chrome plating should weigh the balance of cost versus desired durability and aesthetic appeal.

Environmental and Safety Considerations

Nickel plating generates hazardous waste containing toxic heavy metals and often requires strict disposal methods to prevent soil and water contamination. Chrome plating, especially hexavalent chromium processes, poses significant health risks including respiratory issues and carcinogenic exposure, necessitating rigorous ventilation and protective equipment. Both industries are increasingly adopting trivalent chromium and advanced filtration systems to mitigate environmental impact and enhance worker safety.

Maintenance and Longevity

Nickel plating offers excellent corrosion resistance and durability, making maintenance relatively simple with occasional cleaning to prevent oxidation. Chrome plating provides a harder surface with superior abrasion resistance but may chip or peel over time, requiring more careful upkeep. Your choice depends on whether you prioritize easier maintenance and corrosion protection (nickel) or a highly polished, wear-resistant finish (chrome) for long-term use.

Choosing the Right Plating for Your Needs

Nickel plating offers excellent corrosion resistance and provides a smooth, uniform finish ideal for enhancing durability and wear resistance in industrial applications. Chrome plating delivers superior hardness and a highly reflective, decorative appearance, making it ideal for automotive parts and aesthetic enhancements. Selecting the right plating depends on balancing functional requirements like corrosion protection, hardness, and visual appeal to meet specific project goals.

nickel plating vs chrome plating Infographic

libmatt.com

libmatt.com