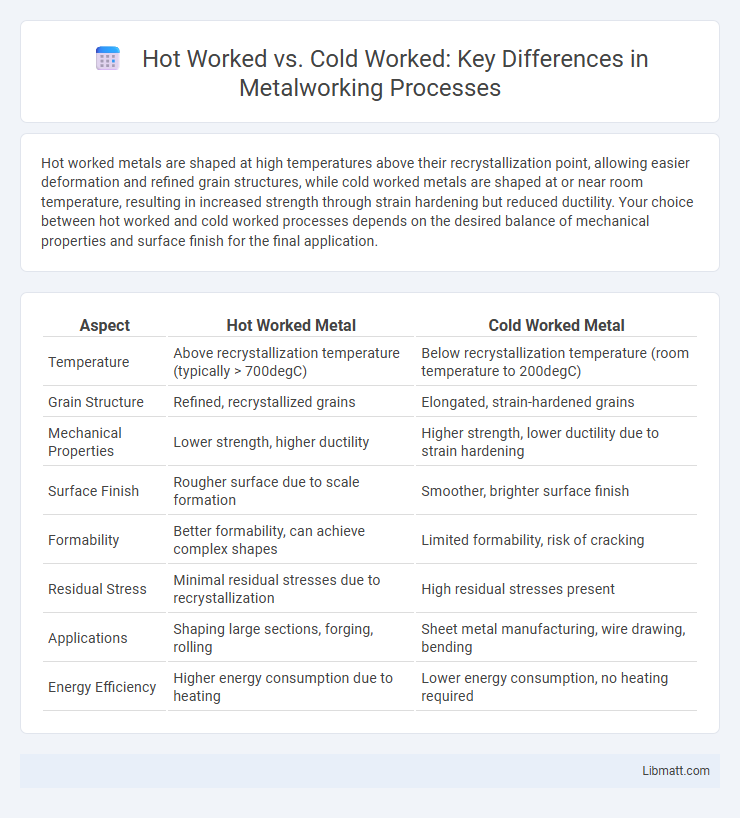

Hot worked metals are shaped at high temperatures above their recrystallization point, allowing easier deformation and refined grain structures, while cold worked metals are shaped at or near room temperature, resulting in increased strength through strain hardening but reduced ductility. Your choice between hot worked and cold worked processes depends on the desired balance of mechanical properties and surface finish for the final application.

Table of Comparison

| Aspect | Hot Worked Metal | Cold Worked Metal |

|---|---|---|

| Temperature | Above recrystallization temperature (typically > 700degC) | Below recrystallization temperature (room temperature to 200degC) |

| Grain Structure | Refined, recrystallized grains | Elongated, strain-hardened grains |

| Mechanical Properties | Lower strength, higher ductility | Higher strength, lower ductility due to strain hardening |

| Surface Finish | Rougher surface due to scale formation | Smoother, brighter surface finish |

| Formability | Better formability, can achieve complex shapes | Limited formability, risk of cracking |

| Residual Stress | Minimal residual stresses due to recrystallization | High residual stresses present |

| Applications | Shaping large sections, forging, rolling | Sheet metal manufacturing, wire drawing, bending |

| Energy Efficiency | Higher energy consumption due to heating | Lower energy consumption, no heating required |

Introduction to Hot Worked and Cold Worked Processes

Hot worked processes involve deforming metals above their recrystallization temperature, allowing for easier shaping and improved ductility, commonly used in forging, rolling, and extrusion. Cold worked processes occur below the recrystallization temperature, increasing strength and hardness through strain hardening while maintaining tighter dimensional tolerances, typical in processes such as cold rolling and drawing. Understanding the temperature-dependent behavior and mechanical property changes is essential for selecting appropriate manufacturing methods in metal forming.

Defining Hot Working: Key Characteristics

Hot working refers to the process of shaping metals at temperatures above their recrystallization point, typically exceeding 70% of the metal's melting temperature. This method allows for significant deformation without strain hardening, enabling improved ductility and refined grain structure. Key characteristics include enhanced plasticity, reduced internal stresses, and the elimination of defects like porosity or segregation.

Defining Cold Working: Essential Features

Cold working involves deforming metal below its recrystallization temperature, enhancing strength through strain hardening without altering the metal's inherent crystal structure. This process results in increased hardness, improved surface finish, and tighter dimensional tolerances compared to hot working. Common cold working techniques include rolling, drawing, and pressing, which optimize mechanical properties while preserving material integrity.

Temperature Differences in Metalworking Processes

Hot worked metals are processed at temperatures above their recrystallization point, typically ranging from 600degC to 1200degC, allowing for easier deformation and eliminating work hardening. Cold worked metals are shaped below their recrystallization temperature, usually at ambient temperatures, which increases strength and hardness due to strain hardening but requires more force and can introduce residual stresses. Temperature differences critically affect the microstructure, mechanical properties, and energy consumption in metalworking processes.

Mechanical Properties: Hot Worked vs Cold Worked Metals

Hot worked metals typically exhibit improved ductility and reduced strength due to recrystallization at elevated temperatures, allowing easier shaping with less residual stress. Cold worked metals display higher tensile strength and hardness because of strain hardening but may suffer from reduced ductility and increased brittleness. Understanding these mechanical property differences helps you select the appropriate process for your metal forming and performance requirements.

Advantages of Hot Working

Hot working offers significant advantages such as improved material ductility and reduced risk of work hardening, enabling easier deformation of metals. It enhances grain refinement, leading to better mechanical properties and structural uniformity. This process allows for shaping large components with complex geometries while minimizing residual stresses and defects.

Advantages of Cold Working

Cold working enhances the strength and hardness of metals through strain hardening, improving their mechanical properties without altering the material's grain structure. This process offers better surface finish and dimensional accuracy compared to hot working, making it ideal for precision components. You benefit from increased material strength and improved fatigue resistance, which are critical for high-performance applications.

Applications: When to Use Hot Worked or Cold Worked Metals

Hot worked metals are ideal for large-scale structural components, such as beams and rails, where improved ductility and reduced residual stresses are essential for applications in construction and heavy machinery. Cold worked metals offer superior surface finish and increased strength, making them suitable for precision parts like gears, springs, and fasteners used in automotive and aerospace industries. Your choice between hot worked and cold worked metals should depend on whether dimensional accuracy or mechanical strength is the priority in your specific application.

Surface Finish and Dimensional Accuracy Comparison

Hot worked metals typically have a rougher surface finish due to scale formation and slower cooling rates, whereas cold worked metals offer a smoother, more refined surface resulting from deformation below recrystallization temperature. In terms of dimensional accuracy, cold working provides tighter tolerances and enhanced precision, while hot working may lead to dimensional variations caused by thermal expansion and contraction. Your choice between hot worked and cold worked materials should consider these differences to meet specific surface quality and dimensional requirements.

Choosing Between Hot Worked and Cold Worked Methods

Choosing between hot worked and cold worked methods depends on the material properties and desired final product. Hot worked metals offer improved ductility and reduced residual stresses due to processing above recrystallization temperature, while cold worked metals provide superior surface finish and increased strength through strain hardening. Your selection should consider factors such as dimensional accuracy, mechanical performance, and cost-efficiency for optimal manufacturing outcomes.

Hot Worked vs Cold Worked Infographic

libmatt.com

libmatt.com