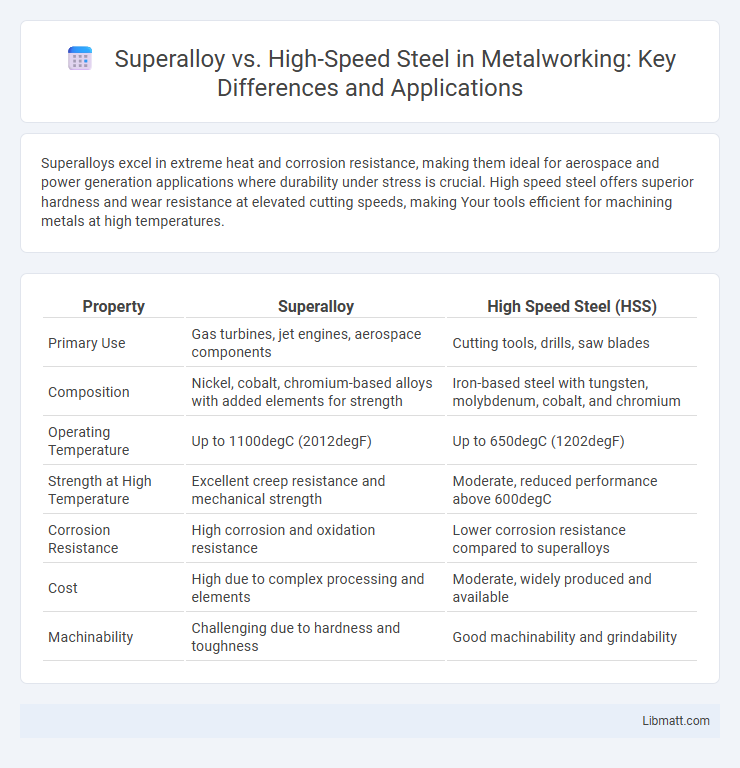

Superalloys excel in extreme heat and corrosion resistance, making them ideal for aerospace and power generation applications where durability under stress is crucial. High speed steel offers superior hardness and wear resistance at elevated cutting speeds, making Your tools efficient for machining metals at high temperatures.

Table of Comparison

| Property | Superalloy | High Speed Steel (HSS) |

|---|---|---|

| Primary Use | Gas turbines, jet engines, aerospace components | Cutting tools, drills, saw blades |

| Composition | Nickel, cobalt, chromium-based alloys with added elements for strength | Iron-based steel with tungsten, molybdenum, cobalt, and chromium |

| Operating Temperature | Up to 1100degC (2012degF) | Up to 650degC (1202degF) |

| Strength at High Temperature | Excellent creep resistance and mechanical strength | Moderate, reduced performance above 600degC |

| Corrosion Resistance | High corrosion and oxidation resistance | Lower corrosion resistance compared to superalloys |

| Cost | High due to complex processing and elements | Moderate, widely produced and available |

| Machinability | Challenging due to hardness and toughness | Good machinability and grindability |

Introduction to Superalloy and High Speed Steel

Superalloys are advanced metal alloys primarily composed of nickel, cobalt, or iron, designed to maintain exceptional mechanical strength and corrosion resistance at elevated temperatures above 700degC. High speed steel (HSS), predominantly composed of iron with significant alloying elements like tungsten, molybdenum, and vanadium, is engineered for retaining hardness and wear resistance during high-speed cutting operations up to 600degC. Both materials serve critical roles in aerospace, power generation, and cutting tool industries, with superalloys excelling in extreme thermal environments and HSS optimized for high-speed machining performance.

Chemical Composition Comparison

Superalloys primarily consist of nickel, cobalt, or iron with additions of chromium, aluminum, titanium, and other elements to enhance high-temperature strength and corrosion resistance, whereas high speed steel (HSS) contains a higher percentage of carbon, tungsten, molybdenum, and vanadium to improve hardness and wear resistance. The complex alloying elements in superalloys provide superior oxidation resistance and mechanical properties at extreme temperatures compared to HSS, which is optimized for cutting tool performance at high speeds. Your choice between these materials depends on the required balance of heat resistance and hardness for specific industrial applications.

Mechanical Properties Overview

Superalloys exhibit exceptional mechanical properties including high tensile strength, creep resistance, and thermal stability at extreme temperatures, making them ideal for aerospace and power generation applications. High-speed steels (HSS) provide excellent hardness, wear resistance, and toughness at elevated temperatures, suitable for cutting tools and machinery components. While superalloys maintain mechanical integrity under prolonged thermal stress, HSS excels in maintaining sharp edges and resistance to deformation during high-speed machining operations.

Heat Resistance and Thermal Stability

Superalloys exhibit superior heat resistance and thermal stability compared to high speed steel, maintaining mechanical properties at temperatures exceeding 700degC, whereas high speed steel typically operates effectively up to around 600degC. The advanced cobalt, nickel, and chromium-based composition of superalloys enhances their oxidation resistance and prevents structural degradation under prolonged high-temperature exposure. High speed steel's carbon and tungsten-rich matrix provides good hardness retention under heat but cannot match the long-term thermal stability or corrosion resistance of superalloys in extreme environments.

Wear and Corrosion Resistance

Superalloys exhibit superior wear and corrosion resistance compared to high speed steel, making them ideal for extreme environments involving high temperatures and oxidative conditions. High speed steel offers good wear resistance under moderate conditions but tends to degrade faster when exposed to corrosive elements. Your choice depends on the operational demands, with superalloys preferred for durability and longevity in harsh applications.

Applications in Industry

Superalloys are extensively used in aerospace, power generation, and chemical processing industries due to their exceptional high-temperature strength and corrosion resistance. High speed steels dominate cutting tool manufacturing, including drills, taps, and milling cutters, thanks to their hardness and wear resistance at elevated temperatures. Both materials are critical in environments requiring durability, but superalloys excel in extreme thermal and oxidative conditions, while high speed steel remains preferred for precision machining applications.

Machinability and Fabrication

Superalloys exhibit lower machinability compared to high speed steel due to their high strength and thermal resistance, often requiring specialized cutting tools and slower machining speeds. Fabrication of superalloys involves advanced techniques like precision casting or powder metallurgy to maintain structural integrity under extreme conditions. Your choice between these materials should consider the trade-off between high speed steel's ease of machining and superalloy's superior performance in demanding environments.

Cost and Economic Considerations

Superalloys typically exhibit higher costs due to expensive raw materials like nickel and complex manufacturing processes, which can significantly impact your project budget. High speed steel offers a more economical choice for tooling and cutting applications, balancing price with adequate performance in less extreme conditions. Evaluating cost-effectiveness requires considering the application's thermal and mechanical demands to justify the investment in superalloys versus the affordability of high speed steel.

Lifespan and Performance Efficiency

Superalloys demonstrate superior lifespan and performance efficiency compared to high-speed steel due to their exceptional resistance to thermal degradation and mechanical wear at elevated temperatures. High-speed steel, while offering good hardness and wear resistance at moderate temperatures, tends to lose hardness and durability under extreme heat, limiting its application longevity. The advanced microstructure and alloy composition of superalloys enable sustained performance in high-stress environments, making them ideal for aerospace and turbine blade applications where durability and efficiency are critical.

Choosing the Right Material for Your Needs

Superalloys offer exceptional heat resistance and strength at high temperatures, making them ideal for aerospace and turbine applications, while high speed steel excels in wear resistance and toughness for cutting tools and machining operations. Choosing the right material depends on your specific requirements for temperature endurance, mechanical stress, and durability in the working environment. Evaluate the operational conditions and desired lifespan to determine whether the thermal stability of superalloys or the hardness and toughness of high speed steel better suits your needs.

Superalloy vs high speed steel Infographic

libmatt.com

libmatt.com