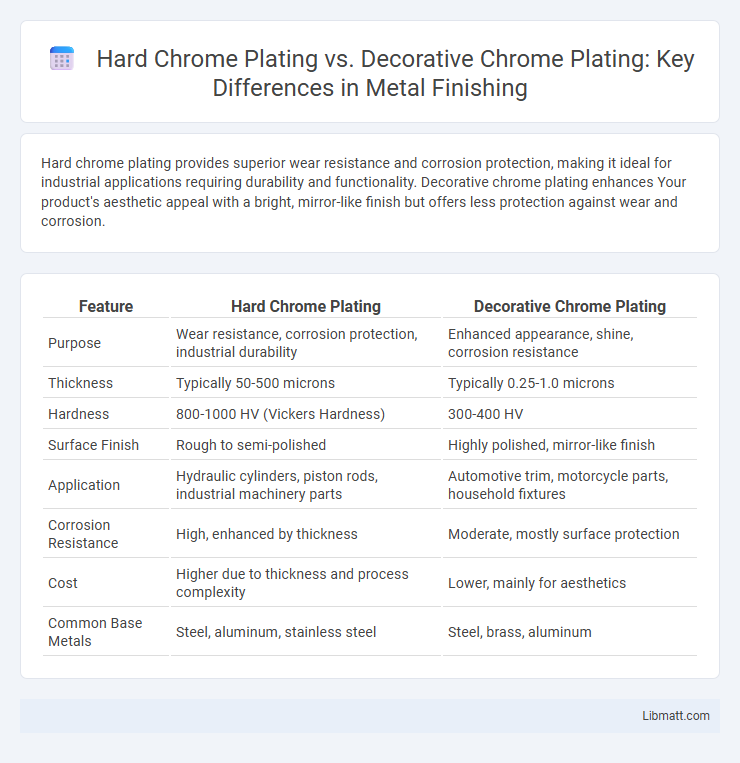

Hard chrome plating provides superior wear resistance and corrosion protection, making it ideal for industrial applications requiring durability and functionality. Decorative chrome plating enhances Your product's aesthetic appeal with a bright, mirror-like finish but offers less protection against wear and corrosion.

Table of Comparison

| Feature | Hard Chrome Plating | Decorative Chrome Plating |

|---|---|---|

| Purpose | Wear resistance, corrosion protection, industrial durability | Enhanced appearance, shine, corrosion resistance |

| Thickness | Typically 50-500 microns | Typically 0.25-1.0 microns |

| Hardness | 800-1000 HV (Vickers Hardness) | 300-400 HV |

| Surface Finish | Rough to semi-polished | Highly polished, mirror-like finish |

| Application | Hydraulic cylinders, piston rods, industrial machinery parts | Automotive trim, motorcycle parts, household fixtures |

| Corrosion Resistance | High, enhanced by thickness | Moderate, mostly surface protection |

| Cost | Higher due to thickness and process complexity | Lower, mainly for aesthetics |

| Common Base Metals | Steel, aluminum, stainless steel | Steel, brass, aluminum |

Introduction to Chrome Plating Processes

Hard chrome plating involves applying a thick layer of chromium to metal surfaces to enhance wear resistance, corrosion protection, and durability, commonly used in industrial and automotive applications. Decorative chrome plating, in contrast, deposits a thinner chromium layer primarily for aesthetic appeal and corrosion resistance on consumer goods like automotive trim and household fixtures. Both processes utilize electroplating techniques but differ significantly in thickness, purpose, and performance characteristics.

What is Hard Chrome Plating?

Hard chrome plating is an electroplating process that deposits a thick layer of chromium onto metal surfaces to enhance wear resistance, reduce friction, and improve corrosion protection. It typically involves a thickness ranging from 25 to 250 microns, making it ideal for industrial applications such as automotive parts, hydraulic cylinders, and molds. Unlike decorative chrome plating, hard chrome plating prioritizes functionality and durability over appearance, providing superior hardness and extending the lifespan of machinery components.

What is Decorative Chrome Plating?

Decorative chrome plating is a metal finishing process primarily used to enhance the appearance of objects by applying a thin layer of chromium onto a substrate, typically steel or plastic. It provides a shiny, reflective, and corrosion-resistant surface, often found on automotive parts, household fixtures, and consumer electronics. Unlike hard chrome plating, decorative chrome plating is thinner and focuses on aesthetics rather than wear resistance or durability.

Composition and Materials Used

Hard chrome plating primarily utilizes a thick layer of chromium deposited over a steel or metal substrate using an electrolytic process, often with a high chromium content around 99%; it is designed for durability and wear resistance. Decorative chrome plating involves a thin layer of chromium applied over a base layer, typically nickel or copper, enhancing corrosion resistance and aesthetic shine with lower chromium thickness. The key materials differ in thickness and layering: hard chrome employs a thick high-purity chromium layer for industrial use, while decorative chrome relies on thin chromium over nickel-copper bases for visual appeal.

Differences in Application and Purpose

Hard chrome plating is primarily used for industrial applications requiring wear resistance, corrosion protection, and enhanced surface hardness on machine parts such as hydraulic cylinders and molds. Decorative chrome plating serves an aesthetic purpose, providing a shiny, mirror-like finish on automotive trim, household fixtures, and consumer goods to enhance visual appeal. Your choice between hard and decorative chrome plating depends on whether functionality or appearance is the primary objective.

Key Performance Characteristics

Hard chrome plating offers superior wear resistance, high hardness up to 70 Rockwell C, and excellent corrosion protection, making it ideal for industrial applications such as hydraulic cylinders and molds. Decorative chrome plating emphasizes aesthetic appeal with a bright, mirror-like finish and moderate corrosion resistance, typically applied on automotive parts and household fixtures. Hard chrome layers are typically thicker (25-250 microns) than decorative chrome (0.05-0.5 microns), influencing their distinct performance in durability and appearance.

Durability and Wear Resistance Compared

Hard chrome plating offers superior durability and wear resistance compared to decorative chrome plating, making it ideal for industrial applications where surface hardness and abrasion resistance are critical. Decorative chrome plating primarily enhances aesthetic appeal and corrosion resistance but lacks the thickness and toughness required for heavy-duty use. Your choice between the two should depend on whether functional performance or visual enhancement is the priority.

Aesthetic Qualities and Finish Options

Hard chrome plating offers a matte to semi-bright finish primarily valued for durability and corrosion resistance, making it ideal for industrial applications where wear protection is critical. Decorative chrome plating provides a highly reflective, mirror-like finish with superior aesthetic appeal, commonly used in automotive and household fixtures to enhance visual attractiveness. Both finishes accommodate various thicknesses, but decorative plating prioritizes smoothness and brightness to achieve a premium look, while hard chrome focuses on functional performance.

Environmental and Safety Considerations

Hard chrome plating involves the use of hexavalent chromium, a hazardous substance with strict regulations due to its carcinogenic properties, requiring advanced ventilation and waste treatment systems to ensure worker safety and environmental protection. Decorative chrome plating typically uses trivalent chromium, which is less toxic and poses fewer environmental risks, making it a safer choice for applications focused on aesthetics. Your decision between these plating options should weigh the environmental impact and compliance with safety standards relevant to your industry and project requirements.

Choosing the Right Chrome Plating for Your Needs

Hard chrome plating offers superior wear resistance, corrosion protection, and thickness, making it ideal for industrial applications such as hydraulic cylinders and machinery parts requiring durability. Decorative chrome plating provides a smooth, shiny finish mainly used for aesthetic purposes on automotive parts, household fixtures, and furniture. Understanding your requirements for functionality versus appearance helps ensure your choice of chrome plating aligns with your project's performance and visual goals.

Hard Chrome Plating vs Decorative Chrome Plating Infographic

libmatt.com

libmatt.com