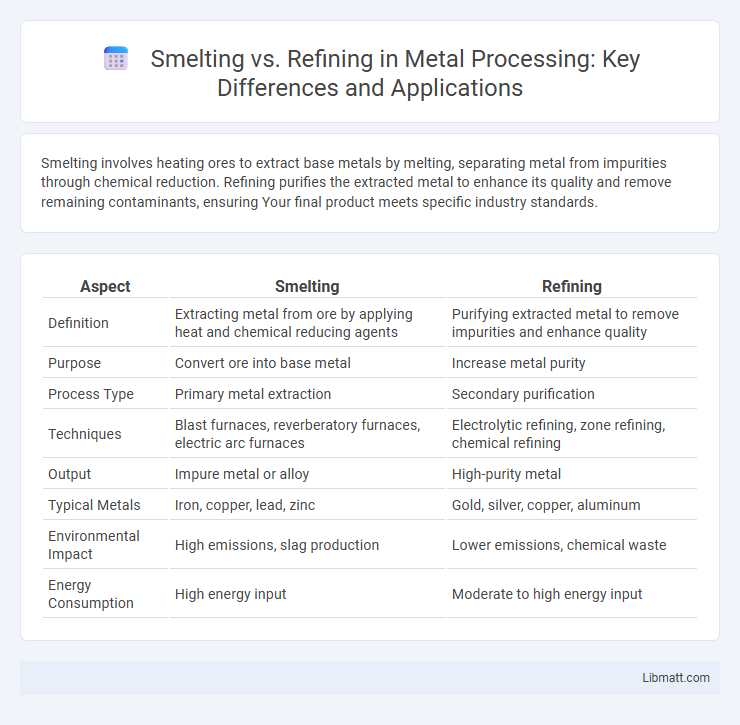

Smelting involves heating ores to extract base metals by melting, separating metal from impurities through chemical reduction. Refining purifies the extracted metal to enhance its quality and remove remaining contaminants, ensuring Your final product meets specific industry standards.

Table of Comparison

| Aspect | Smelting | Refining |

|---|---|---|

| Definition | Extracting metal from ore by applying heat and chemical reducing agents | Purifying extracted metal to remove impurities and enhance quality |

| Purpose | Convert ore into base metal | Increase metal purity |

| Process Type | Primary metal extraction | Secondary purification |

| Techniques | Blast furnaces, reverberatory furnaces, electric arc furnaces | Electrolytic refining, zone refining, chemical refining |

| Output | Impure metal or alloy | High-purity metal |

| Typical Metals | Iron, copper, lead, zinc | Gold, silver, copper, aluminum |

| Environmental Impact | High emissions, slag production | Lower emissions, chemical waste |

| Energy Consumption | High energy input | Moderate to high energy input |

Introduction to Smelting and Refining

Smelting involves heating ore to extract base metals by separating impurities through melting, while refining purifies these extracted metals to achieve desired chemical composition and quality. You can find smelting primarily used in metal extraction industries like iron, copper, and aluminum production, whereas refining is crucial for enhancing purity in sectors such as jewelry and electronics. Both processes optimize metal usability by transforming raw ore into high-grade final products.

Definition of Smelting

Smelting is a metallurgical process that involves heating ore to a high temperature to extract a base metal by separating it from impurities. This process typically uses a furnace and a chemical reducing agent such as coke or charcoal to facilitate the extraction. Understanding smelting is essential for your work in metal production to ensure efficient mineral recovery before refining.

Definition of Refining

Refining is the process of purifying a metal or mineral by removing impurities to achieve the desired chemical composition and quality. Unlike smelting, which involves extracting metal from ore by melting and separating it from waste, refining focuses on enhancing the purity of already extracted metals. Understanding refining helps you ensure that your metals meet industry standards for performance and durability.

Key Differences Between Smelting and Refining

Smelting involves heating ore to extract a base metal by melting and separating impurities, primarily focusing on the initial extraction process. Refining is the subsequent step that purifies the extracted metal to achieve desired purity levels through chemical or electrolytic methods. Understanding these key differences helps you optimize metal production workflows and enhance material quality.

Processes Involved in Smelting

Smelting involves heating ore to high temperatures in a furnace to extract base metals by separating them from impurities through chemical reduction or melting. Key processes include roasting to remove sulfur and other volatile components, followed by reduction where oxygen is removed from metal oxides to yield the pure metal. Understanding these steps in smelting helps optimize your metal extraction for better yield and quality.

Processes Involved in Refining

Refining involves processes such as electrolysis, chemical treatment, and thermal methods to purify metals by removing impurities and unwanted elements. These methods enhance metal quality and ensure consistent chemical composition by separating base metals from other compounds. You can rely on refining to produce metals suitable for industrial applications, jewelry, and electronics with superior purity.

Common Materials Used in Smelting and Refining

Smelting commonly involves ores such as iron ore, copper ore, and aluminum ore, where high temperatures extract metals by melting and separating impurities. Refining further purifies these extracted metals, often using materials like electrolysis solutions for copper or chemical agents in aluminum to achieve higher purity levels. Understanding the common materials in smelting and refining helps you optimize the metal production process for improved quality and efficiency.

Environmental Impact: Smelting vs Refining

Smelting generates significant environmental pollution through the release of sulfur dioxide and heavy metals, contributing to air and water contamination. Refining processes, especially electrolytic refining, offer cleaner alternatives by minimizing harmful emissions and facilitating the recycling of metals. Understanding these differences helps you choose more sustainable methods in metal production and processing.

Industrial Applications of Smelting and Refining

Smelting is widely used in the metallurgical industry to extract base metals like iron, copper, and lead from ores through high-temperature chemical reduction processes. Refining, on the other hand, is crucial in producing high-purity metals, such as aluminum and gold, by removing impurities through electrolysis, chemical treatment, or distillation. Both processes play essential roles in manufacturing sectors including automotive, aerospace, and electronics, where precise material properties and metal purity are critical.

Conclusion: Choosing Between Smelting and Refining

Choosing between smelting and refining depends on the stage of metal processing and the desired purity level. Smelting is ideal for extracting metal from ore through high-temperature chemical reactions, while refining focuses on purifying the extracted metal to achieve specific quality standards. Your choice should align with whether the goal is initial metal extraction or enhancement of metal quality.

Smelting vs Refining Infographic

libmatt.com

libmatt.com