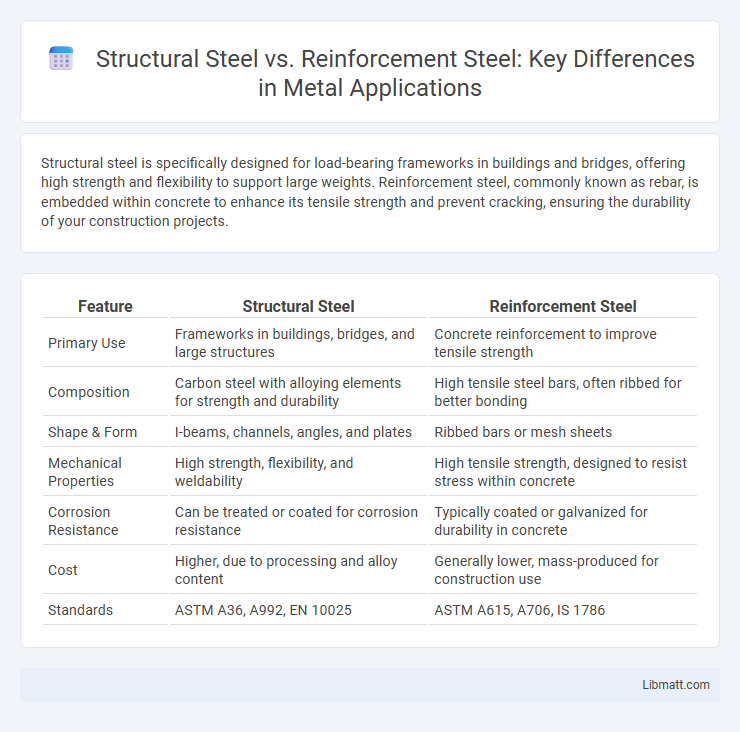

Structural steel is specifically designed for load-bearing frameworks in buildings and bridges, offering high strength and flexibility to support large weights. Reinforcement steel, commonly known as rebar, is embedded within concrete to enhance its tensile strength and prevent cracking, ensuring the durability of your construction projects.

Table of Comparison

| Feature | Structural Steel | Reinforcement Steel |

|---|---|---|

| Primary Use | Frameworks in buildings, bridges, and large structures | Concrete reinforcement to improve tensile strength |

| Composition | Carbon steel with alloying elements for strength and durability | High tensile steel bars, often ribbed for better bonding |

| Shape & Form | I-beams, channels, angles, and plates | Ribbed bars or mesh sheets |

| Mechanical Properties | High strength, flexibility, and weldability | High tensile strength, designed to resist stress within concrete |

| Corrosion Resistance | Can be treated or coated for corrosion resistance | Typically coated or galvanized for durability in concrete |

| Cost | Higher, due to processing and alloy content | Generally lower, mass-produced for construction use |

| Standards | ASTM A36, A992, EN 10025 | ASTM A615, A706, IS 1786 |

Introduction to Structural Steel and Reinforcement Steel

Structural steel is a versatile material widely used in construction for building frameworks due to its high strength, durability, and flexibility, making it ideal for large structures and load-bearing applications. Reinforcement steel, often called rebar, is specifically designed to strengthen concrete by providing tensile strength and preventing cracking, ensuring the structural integrity of concrete elements. Understanding the differences between these materials helps you select the appropriate steel type for specific construction needs, enhancing safety and performance.

Definitions and Core Differences

Structural steel is a category of steel used primarily for building frameworks and infrastructure, valued for its strength, durability, and ability to withstand heavy loads. Reinforcement steel, also known as rebar, serves specifically to enhance the tensile strength of concrete structures by providing internal support and preventing cracking. Understanding the distinct roles of these materials helps you choose appropriate steel types for construction projects, ensuring safety and structural integrity.

Chemical Composition and Properties

Structural steel primarily consists of carbon, manganese, silicon, and traces of sulfur and phosphorus, offering high tensile strength, ductility, and weldability ideal for load-bearing frameworks. Reinforcement steel, commonly known as rebar, contains a higher carbon content and ribbed surface for better bond with concrete, enhancing tensile strength and corrosion resistance in concrete structures. Understanding the chemical composition and mechanical properties of both steels helps you select the best material for construction durability and safety.

Applications in Construction

Structural steel is primarily used in the framework of buildings, bridges, and industrial structures due to its high strength-to-weight ratio and flexibility in design. Reinforcement steel, also known as rebar, is embedded within concrete to enhance tensile strength, making it essential in foundations, slabs, beams, and columns. Both materials are critical in modern construction, with structural steel supporting load-bearing frameworks while reinforcement steel ensures concrete durability and resistance to cracking.

Mechanical Strength and Load-Bearing Capacity

Structural steel exhibits higher tensile strength and superior load-bearing capacity compared to reinforcement steel, making it ideal for primary frameworks in construction. Reinforcement steel, commonly known as rebar, is designed to enhance concrete's tensile strength and prevent cracking under tension. Your choice depends on the specific mechanical requirements and structural demands of the project.

Fabrication and Installation Methods

Structural steel fabrication involves cutting, welding, and assembling large beams and columns in controlled environments before on-site installation using cranes and bolted or welded connections. Reinforcement steel, or rebar, is typically cut and bent on-site or pre-fabricated into cages that are then placed within concrete forms and secured with ties or wire to ensure proper bonding. Your choice between these steels impacts project timelines and labor requirements due to the differing handling and installation techniques.

Corrosion Resistance and Durability

Reinforcement steel typically requires protective coatings or concrete encasement to enhance corrosion resistance, as it is prone to rust in humid or marine environments. Structural steel often undergoes galvanization or weathering treatments, significantly improving its durability against environmental factors. The choice between the two depends on specific application demands, with structural steel favored for exposed frameworks and reinforcement steel essential for concrete reinforcement despite its vulnerability to corrosion.

Cost Comparison: Structural vs Reinforcement Steel

Structural steel generally incurs higher initial costs due to its fabrication and installation complexity, while reinforcement steel is more cost-effective for concrete strengthening applications. Price variations depend on market demand, grade, and quantity, with reinforcement steel often priced lower per ton compared to structural steel beams and shapes. Long-term expenses also differ, as structural steel offers superior durability and load-bearing capacity, potentially reducing maintenance and replacement costs over time.

Standards and Certification Requirements

Structural steel complies with rigorous standards such as ASTM A36 or EN 10025, ensuring high tensile strength and durability for load-bearing frameworks in construction. Reinforcement steel, commonly referred to as rebar, must meet certification requirements like ASTM A615 or BS 4449, focusing on tensile strength and flexibility to reinforce concrete structures effectively. Your project's safety and longevity depend on using certified materials that meet these specific standards to guarantee performance and compliance.

Conclusion: Choosing the Right Steel for Your Project

Choosing the right steel for your project depends on the intended structural purpose and load requirements. Structural steel provides high strength and flexibility for frameworks in buildings or bridges, while reinforcement steel enhances concrete's tensile strength for durability and crack resistance. Understanding these functional differences ensures your construction achieves optimal safety, stability, and longevity.

Structural Steel vs Reinforcement Steel Infographic

libmatt.com

libmatt.com