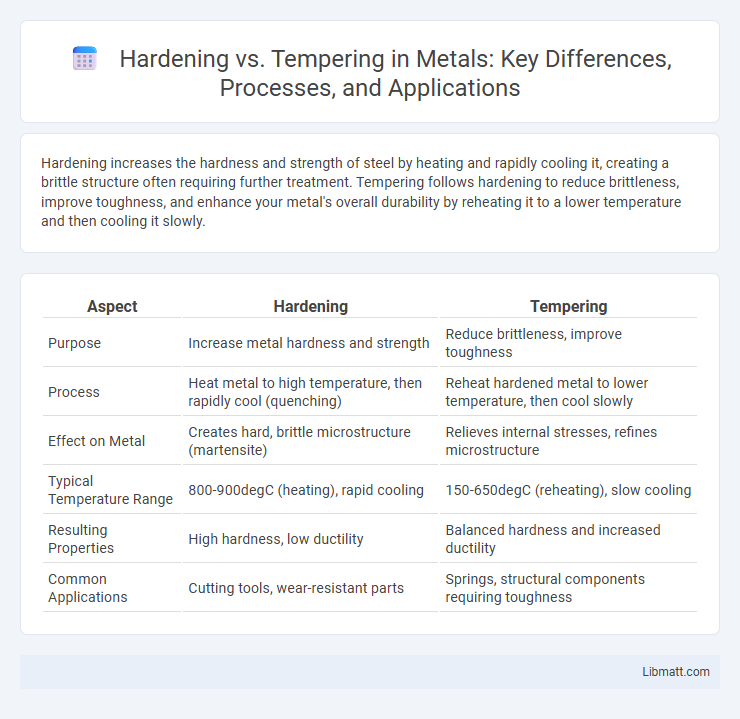

Hardening increases the hardness and strength of steel by heating and rapidly cooling it, creating a brittle structure often requiring further treatment. Tempering follows hardening to reduce brittleness, improve toughness, and enhance your metal's overall durability by reheating it to a lower temperature and then cooling it slowly.

Table of Comparison

| Aspect | Hardening | Tempering |

|---|---|---|

| Purpose | Increase metal hardness and strength | Reduce brittleness, improve toughness |

| Process | Heat metal to high temperature, then rapidly cool (quenching) | Reheat hardened metal to lower temperature, then cool slowly |

| Effect on Metal | Creates hard, brittle microstructure (martensite) | Relieves internal stresses, refines microstructure |

| Typical Temperature Range | 800-900degC (heating), rapid cooling | 150-650degC (reheating), slow cooling |

| Resulting Properties | High hardness, low ductility | Balanced hardness and increased ductility |

| Common Applications | Cutting tools, wear-resistant parts | Springs, structural components requiring toughness |

Introduction to Heat Treatment Processes

Heat treatment processes such as hardening and tempering manipulate the microstructure of metals to enhance mechanical properties. Hardening involves rapid cooling or quenching to increase hardness and strength by forming martensite in steel. Tempering follows hardening, reheating the steel to a lower temperature to reduce brittleness and improve toughness while maintaining hardness.

Defining Hardening and Tempering

Hardening is a heat treatment process that increases the hardness and strength of metal by heating it to a high temperature and then rapidly cooling it, usually through quenching. Tempering follows hardening and involves reheating the quenched metal to a lower temperature to reduce brittleness while maintaining a desired level of hardness. Your choice between hardening and tempering depends on the required balance of hardness, toughness, and durability for the specific application.

Key Differences Between Hardening and Tempering

Hardening involves rapidly cooling steel from a high temperature to increase its hardness and strength, while tempering follows by reheating the hardened steel to a lower temperature to reduce brittleness and improve toughness. The key difference lies in their purpose: hardening aims to create a hard, wear-resistant material, whereas tempering balances hardness with ductility to prevent cracking. Your choice between these processes depends on the desired mechanical properties for the specific application.

Purpose and Applications of Hardening

Hardening increases steel's hardness and strength by rapidly cooling it after heating, creating a more wear-resistant and durable material. This process is essential in manufacturing cutting tools, automotive parts, and machinery components that require high surface hardness to resist abrasion and deformation. Understanding hardening can improve your ability to select materials for applications where toughness and longevity are critical.

Purpose and Applications of Tempering

Tempering is a heat treatment process aimed at reducing the brittleness of hardened steel while maintaining its hardness and strength, enhancing toughness and ductility. It is widely applied in manufacturing components such as automotive parts, cutting tools, and structural elements that require a balance of strength and resistance to impact. The controlled reheating to a specific temperature allows the microstructure to stabilize, preventing fractures during use.

Step-by-Step Hardening Process Overview

The hardening process begins with heating steel to its critical temperature, typically between 800degC and 900degC, to transform its microstructure into austenite. The steel is then rapidly cooled through quenching in water, oil, or air, which transforms the austenite into hard but brittle martensite. Finally, tempering may follow to reduce brittleness by reheating the steel to a lower temperature, usually between 150degC and 650degC, then cooling it slowly to enhance toughness and relieve internal stresses.

Step-by-Step Tempering Process Overview

Tempering involves reheating hardened steel to a temperature between 150degC and 650degC, depending on the desired mechanical properties, followed by controlled cooling to reduce brittleness and increase toughness. The step-by-step process includes heating the steel uniformly, holding it at the target temperature for a specific duration to allow molecular transformation, and then cooling it gradually to room temperature. This controlled thermal cycle optimizes the balance between hardness and ductility, improving the material's overall performance in practical applications.

Effects on Mechanical Properties: Hardness, Toughness, and Ductility

Hardening significantly increases the hardness and strength of steel by transforming its microstructure into martensite, but this process often reduces toughness and ductility, making the material more brittle. Tempering following hardening adjusts the balance by decreasing hardness slightly while substantially improving toughness and ductility through the reduction of internal stresses and refinement of the microstructure. Your choice between hardening and tempering depends on the desired mechanical property balance for specific applications where hardness must be balanced against resistance to fracture and deformation.

Material Suitability for Hardening vs Tempering

Hardening is suitable for high-carbon steels and alloy steels with a carbon content typically above 0.3%, allowing the formation of martensite to increase hardness and wear resistance. Tempering is applied to hardened steels to adjust toughness, reduce brittleness, and improve ductility, making it ideal for materials that require a balance between hardness and impact strength. Materials with low carbon content or those sensitive to cracking are generally less suitable for hardening but can benefit significantly from tempering after mild hardening treatments.

Selecting the Right Technique for Your Application

Selecting the right technique between hardening and tempering depends on the desired balance between strength, hardness, and toughness in your application. Hardening increases material hardness by forming martensite but can create brittleness, while tempering reduces brittleness by relieving stresses and improving ductility. Evaluate factors such as the component's operating environment, load conditions, and required fatigue resistance to determine the optimal heat treatment process.

Hardening vs Tempering Infographic

libmatt.com

libmatt.com