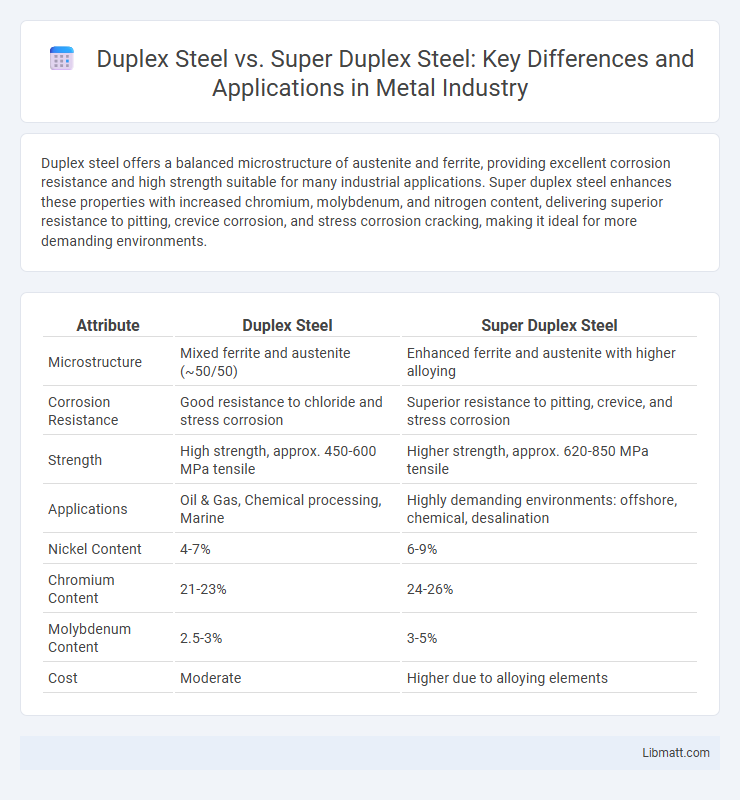

Duplex steel offers a balanced microstructure of austenite and ferrite, providing excellent corrosion resistance and high strength suitable for many industrial applications. Super duplex steel enhances these properties with increased chromium, molybdenum, and nitrogen content, delivering superior resistance to pitting, crevice corrosion, and stress corrosion cracking, making it ideal for more demanding environments.

Table of Comparison

| Attribute | Duplex Steel | Super Duplex Steel |

|---|---|---|

| Microstructure | Mixed ferrite and austenite (~50/50) | Enhanced ferrite and austenite with higher alloying |

| Corrosion Resistance | Good resistance to chloride and stress corrosion | Superior resistance to pitting, crevice, and stress corrosion |

| Strength | High strength, approx. 450-600 MPa tensile | Higher strength, approx. 620-850 MPa tensile |

| Applications | Oil & Gas, Chemical processing, Marine | Highly demanding environments: offshore, chemical, desalination |

| Nickel Content | 4-7% | 6-9% |

| Chromium Content | 21-23% | 24-26% |

| Molybdenum Content | 2.5-3% | 3-5% |

| Cost | Moderate | Higher due to alloying elements |

Introduction to Duplex and Super Duplex Steel

Duplex steel is a corrosion-resistant alloy combining austenitic and ferritic stainless steel phases, offering high strength and excellent resistance to stress corrosion cracking in chloride environments. Super duplex steel enhances these properties with a higher alloy content, particularly chromium, molybdenum, and nitrogen, providing superior resistance to pitting, crevice corrosion, and stress corrosion cracking. Both materials are widely used in the oil and gas, chemical processing, and marine industries where durability and corrosion resistance are critical.

Chemical Composition Differences

Duplex Steel typically contains 18-28% chromium, 1-5% nickel, and about 2.5-4% molybdenum, whereas Super Duplex Steel has higher levels with 24-26% chromium, 5-7% nickel, and 3-5% molybdenum. The increased alloying elements in Super Duplex enhance corrosion resistance and strength, particularly against pitting and crevice corrosion in harsh environments. Nitrogen content is also elevated in Super Duplex Steel, contributing to improved mechanical properties and resistance to stress corrosion cracking.

Mechanical Properties Comparison

Super Duplex Steel offers superior mechanical properties compared to Duplex Steel, including higher tensile strength typically around 830-1000 MPa versus 620-880 MPa for Duplex. You benefit from enhanced yield strength and better resistance to stress corrosion cracking due to its balanced microstructure of austenite and ferrite phases. These mechanical advantages make Super Duplex more suitable for demanding environments in oil and gas, chemical processing, and marine applications.

Corrosion Resistance Capabilities

Duplex Steel offers excellent corrosion resistance in environments containing chlorides, with strong performance against stress corrosion cracking and pitting. Super Duplex Steel significantly enhances these capabilities through higher alloy content, providing superior resistance to localized corrosion in more aggressive conditions, such as seawater and chemical processing environments. The increased chromium, molybdenum, and nitrogen levels in Super Duplex result in greater durability and longer service life compared to standard Duplex Steel.

Common Applications in Industry

Duplex steel is commonly used in chemical processing, oil and gas pipelines, and marine environments due to its excellent corrosion resistance and strength. Super duplex steel, with higher alloy content and improved resistance to pitting and stress corrosion, is preferred for more demanding conditions such as offshore platforms, seawater desalination plants, and heat exchangers. Both materials are essential in industries requiring durability under harsh conditions, but super duplex offers superior performance in highly corrosive environments.

Cost and Economic Considerations

Duplex Steel offers a more cost-effective solution for applications with moderate corrosion resistance needs, delivering a balance between performance and price. Super Duplex Steel incurs higher initial costs due to its superior alloy content and enhanced corrosion resistance, but it can provide significant long-term savings by reducing maintenance and replacement expenses in highly aggressive environments. When selecting materials, your decision should weigh upfront investment against the potential economic benefits of durability and lower lifecycle costs.

Weldability and Fabrication Aspects

Duplex steel exhibits good weldability with standard welding techniques like TIG and MIG, but requires precise control of heat input to avoid phase imbalance and reduced corrosion resistance. Super duplex steel demands more stringent welding parameters and the use of low heat input methods to preserve its high strength and corrosion resistance, often necessitating post-weld heat treatment to restore duplex microstructure. Fabrication of super duplex steel is more challenging due to its higher strength and hardness, requiring specialized equipment and skilled operators to prevent cracking and distortion.

Standards and Grades Overview

Duplex Steel typically meets ASTM A182 and EN 10088 standards, encompassing grades like 2205 and 2304, known for their balanced austenitic-ferritic microstructure. Super Duplex Steel adheres to more stringent standards including ASTM A182 F51, F55, and EN 10283, with grades such as 2507 that offer higher corrosion resistance and strength. Your choice depends on the environmental demands and mechanical requirements specified within these recognized standards.

Advantages and Limitations

Duplex Steel offers excellent corrosion resistance and high strength due to its balanced microstructure of austenite and ferrite, making it suitable for many industrial applications. Super Duplex Steel enhances these properties with even greater resistance to chloride stress corrosion cracking and improved mechanical strength but tends to be more expensive and challenging to weld. Your choice depends on balancing the need for superior performance against cost and fabrication complexity.

Selecting the Right Steel for Your Application

Duplex Steel offers balanced corrosion resistance and strength suitable for moderate environments, while Super Duplex Steel provides enhanced durability and superior resistance to chloride-induced stress corrosion cracking, ideal for more aggressive conditions. When selecting the right steel for your application, consider factors such as operating temperature, chemical exposure, and mechanical demands to ensure optimal performance and longevity. Your choice between Duplex and Super Duplex Steel directly impacts maintenance costs and structural integrity in industries like oil and gas, marine, and chemical processing.

Duplex Steel vs Super Duplex Steel Infographic

libmatt.com

libmatt.com