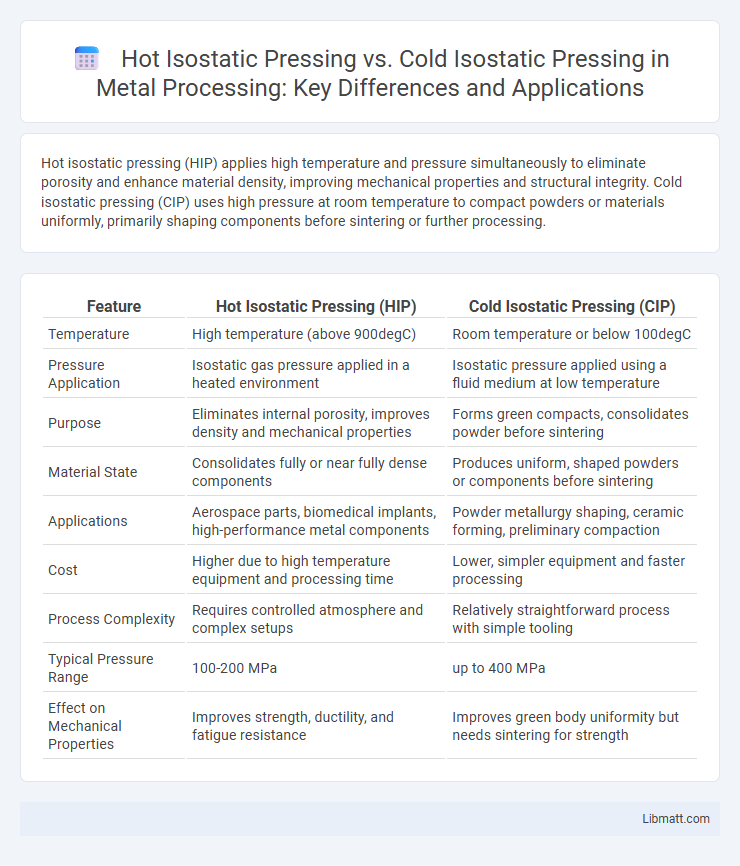

Hot isostatic pressing (HIP) applies high temperature and pressure simultaneously to eliminate porosity and enhance material density, improving mechanical properties and structural integrity. Cold isostatic pressing (CIP) uses high pressure at room temperature to compact powders or materials uniformly, primarily shaping components before sintering or further processing.

Table of Comparison

| Feature | Hot Isostatic Pressing (HIP) | Cold Isostatic Pressing (CIP) |

|---|---|---|

| Temperature | High temperature (above 900degC) | Room temperature or below 100degC |

| Pressure Application | Isostatic gas pressure applied in a heated environment | Isostatic pressure applied using a fluid medium at low temperature |

| Purpose | Eliminates internal porosity, improves density and mechanical properties | Forms green compacts, consolidates powder before sintering |

| Material State | Consolidates fully or near fully dense components | Produces uniform, shaped powders or components before sintering |

| Applications | Aerospace parts, biomedical implants, high-performance metal components | Powder metallurgy shaping, ceramic forming, preliminary compaction |

| Cost | Higher due to high temperature equipment and processing time | Lower, simpler equipment and faster processing |

| Process Complexity | Requires controlled atmosphere and complex setups | Relatively straightforward process with simple tooling |

| Typical Pressure Range | 100-200 MPa | up to 400 MPa |

| Effect on Mechanical Properties | Improves strength, ductility, and fatigue resistance | Improves green body uniformity but needs sintering for strength |

Introduction to Isostatic Pressing

Isostatic pressing applies uniform pressure to materials using fluid or gas, enhancing density and reducing porosity in manufacturing processes. Hot isostatic pressing (HIP) involves high temperature and pressure, promoting material diffusion and eliminating internal defects, while cold isostatic pressing (CIP) operates at room temperature, primarily used for shaping and consolidating powders before sintering. Your choice between HIP and CIP impacts final product strength, microstructure, and overall performance in industrial applications.

Overview of Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is an advanced manufacturing process that applies high temperature and isostatic gas pressure to eliminate internal porosity and improve material density and mechanical properties. Commonly used for metals, ceramics, and composites, HIP enhances fatigue resistance, strength, and structural integrity by promoting diffusion bonding and microstructural refinement. This process is crucial in aerospace, automotive, and medical industries for producing high-performance components with complex geometries and superior quality.

Overview of Cold Isostatic Pressing (CIP)

Cold Isostatic Pressing (CIP) involves applying high pressure uniformly to powder materials at room temperature using a fluid medium, resulting in improved density and uniformity without heat-induced phase changes. This process is essential in producing complex shapes and enhancing mechanical properties in ceramics, metals, and composites. CIP offers advantages like reduced residual stresses and minimized deformation compared to Hot Isostatic Pressing (HIP), making it suitable for delicate or temperature-sensitive materials.

Key Differences Between HIP and CIP

Hot isostatic pressing (HIP) utilizes high temperature and high pressure to densify materials, leading to improved mechanical properties and reduced porosity, whereas cold isostatic pressing (CIP) applies pressure at room temperature mainly for shaping powder compacts. HIP is essential for achieving full density and eliminating internal defects, making it ideal for aerospace and medical implants, while CIP is typically used for preparing green bodies before sintering. The temperature differential in HIP accelerates diffusion and bonding, contrasting with CIP's focus on uniform compaction without phase changes or thermal effects.

Materials Suitable for HIP vs. CIP

Hot Isostatic Pressing (HIP) is ideal for metals, ceramics, and composites that require high-temperature treatment for densification and eliminating internal defects, such as titanium alloys, superalloys, and advanced ceramics like silicon carbide. Cold Isostatic Pressing (CIP) suits powder materials including ceramics, metal powders, and composite powders at ambient or moderate temperatures, primarily used for shaping prior to sintering. HIP achieves full density and improved mechanical properties in high-performance materials, whereas CIP primarily forms green bodies for subsequent thermal processing.

Process Parameters: Pressure, Temperature, and Atmosphere

Hot isostatic pressing (HIP) typically operates at pressures ranging from 100 to 300 MPa and temperatures between 900degC and 2200degC, within an inert or vacuum atmosphere to enhance diffusion and densification. Cold isostatic pressing (CIP) applies pressures up to 400 MPa at room temperature, using a liquid medium like water or oil, without heat or controlled atmosphere, primarily for shaping and initial compaction. Your choice between HIP and CIP depends on the required microstructural properties and material consolidation needs dictated by these distinct process parameters.

Applications of Hot Isostatic Pressing

Hot isostatic pressing (HIP) is widely used in aerospace, automotive, and medical industries for producing high-density, defect-free components such as turbine blades, engine parts, and biomedical implants. Its ability to eliminate internal porosity and improve mechanical properties makes it essential for advanced materials like superalloys, ceramics, and metal matrix composites. HIP is crucial in additive manufacturing post-processing to enhance microstructure and mechanical performance of 3D-printed metal parts.

Applications of Cold Isostatic Pressing

Cold Isostatic Pressing (CIP) is widely used in producing complex-shaped ceramic and metal parts with uniform density, commonly applied in aerospace, automotive, and biomedical industries. CIP optimizes powder compaction for components like advanced ceramics, fuel cells, and cutting tools, enabling enhanced mechanical properties and reduced machining costs. Its ability to form intricate geometries without high temperatures makes CIP ideal for prototyping and small to medium batch manufacturing.

Advantages and Limitations of Each Process

Hot isostatic pressing (HIP) offers advantages such as improved material density, elimination of internal voids, and enhanced mechanical properties due to simultaneous application of heat and pressure, but it involves higher energy consumption and longer cycle times. Cold isostatic pressing (CIP) provides benefits including lower processing costs, preservation of powder particle shape, and suitability for complex geometries, yet it results in lower green density and requires subsequent sintering or HIP for achieving full density. HIP is ideal for critical aerospace and medical components demanding superior performance, while CIP is favored for cost-effective compaction of ceramics and metals with complex shapes.

Conclusion: Choosing Between HIP and CIP

Hot Isostatic Pressing (HIP) and Cold Isostatic Pressing (CIP) serve distinct purposes in material processing, with HIP providing superior densification and mechanical properties by applying high temperature and pressure, while CIP shapes powder without heat, preserving particle purity. Your choice depends on whether enhanced strength and reduced porosity are critical, favoring HIP, or if maintaining material characteristics without thermal influence is a priority, favoring CIP. Assess the component's performance requirements and production costs to determine the optimal isostatic pressing method for your application.

Hot isostatic pressing vs cold isostatic pressing Infographic

libmatt.com

libmatt.com