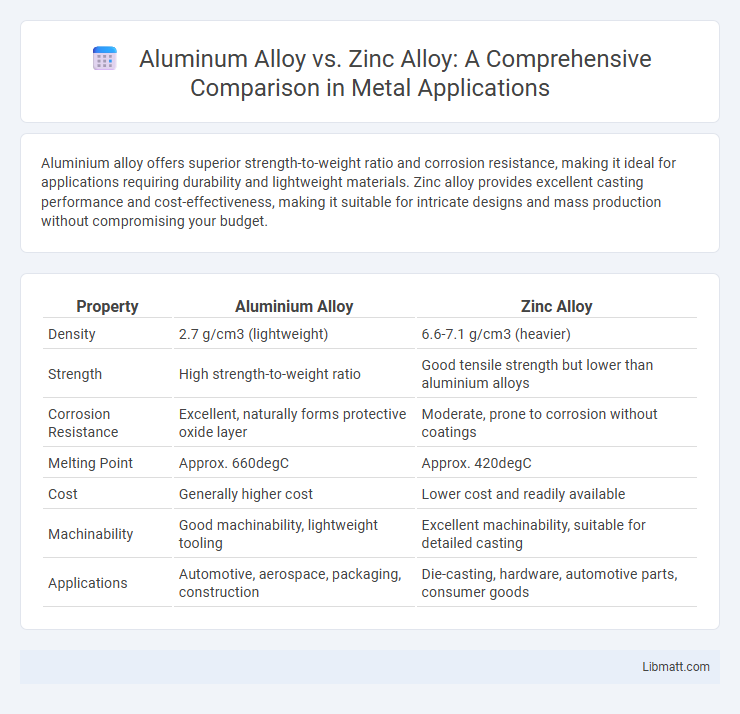

Aluminium alloy offers superior strength-to-weight ratio and corrosion resistance, making it ideal for applications requiring durability and lightweight materials. Zinc alloy provides excellent casting performance and cost-effectiveness, making it suitable for intricate designs and mass production without compromising your budget.

Table of Comparison

| Property | Aluminium Alloy | Zinc Alloy |

|---|---|---|

| Density | 2.7 g/cm3 (lightweight) | 6.6-7.1 g/cm3 (heavier) |

| Strength | High strength-to-weight ratio | Good tensile strength but lower than aluminium alloys |

| Corrosion Resistance | Excellent, naturally forms protective oxide layer | Moderate, prone to corrosion without coatings |

| Melting Point | Approx. 660degC | Approx. 420degC |

| Cost | Generally higher cost | Lower cost and readily available |

| Machinability | Good machinability, lightweight tooling | Excellent machinability, suitable for detailed casting |

| Applications | Automotive, aerospace, packaging, construction | Die-casting, hardware, automotive parts, consumer goods |

Introduction to Aluminium Alloy and Zinc Alloy

Aluminium alloy consists of aluminium combined with elements like copper, magnesium, or silicon to enhance strength, corrosion resistance, and lightweight properties, making it ideal for automotive, aerospace, and construction uses. Zinc alloy, primarily composed of zinc with small amounts of aluminum, copper, or magnesium, offers excellent casting performance, high strength, and corrosion resistance, commonly utilized in die casting and hardware components. Understanding the distinct properties of these alloys helps you choose the right material for durability and functionality in your engineering projects.

Chemical Composition Differences

Aluminium alloys primarily consist of aluminium combined with elements like silicon, copper, magnesium, and zinc to enhance strength and corrosion resistance, typically containing around 90-98% aluminium. Zinc alloys predominantly feature zinc as the base metal, usually around 85-95%, with small amounts of aluminium, copper, and magnesium to improve mechanical properties and casting performance. The key chemical difference lies in aluminium alloys' higher aluminium content for lightweight strength, while zinc alloys use zinc's superior castability and surface finish capabilities.

Mechanical Properties Comparison

Aluminium alloy exhibits higher strength-to-weight ratio and superior corrosion resistance compared to zinc alloy, making it ideal for lightweight structural applications. Zinc alloy offers excellent ductility and impact resistance, providing better performance in applications requiring intricate casting and flexibility. The tensile strength of aluminium alloys typically ranges from 200 to 600 MPa, while zinc alloys generally reach 250 to 400 MPa, influencing their suitability for different mechanical load demands.

Corrosion Resistance and Durability

Aluminium alloy demonstrates superior corrosion resistance due to its natural oxide layer that protects against rust and weathering, making it ideal for outdoor and marine applications. Zinc alloy offers good durability with high impact strength but is more susceptible to corrosion over time, especially in humid or salty environments without protective coatings. Choosing aluminium alloy enhances longevity in harsh conditions, while zinc alloy suits applications where mechanical strength is prioritized over extended corrosion resistance.

Weight and Density Considerations

Aluminium alloy offers a significant advantage over zinc alloy in weight and density, featuring a density of approximately 2.7 g/cm3 compared to zinc alloy's higher density of around 6.6 to 7.1 g/cm3. This difference makes aluminium alloys ideal for applications requiring lightweight materials without compromising strength. Choosing aluminium alloy can reduce the overall weight of your product, enhancing portability and fuel efficiency.

Machinability and Workability

Aluminium alloys exhibit superior machinability due to their lower density and excellent thermal conductivity, allowing for faster cutting speeds and reduced tool wear compared to zinc alloys. Zinc alloys offer excellent workability, especially in casting processes, thanks to their low melting point and high fluidity, making them ideal for intricate shapes and fine details. While aluminium alloys provide better performance in CNC machining and structural applications, zinc alloys excel in precise die casting with minimal post-processing.

Cost and Availability

Aluminium alloy generally offers a cost-effective solution due to its abundance and widespread availability in global markets, making it ideal for large-scale manufacturing. Zinc alloy tends to be more expensive because of its higher material density and limited supply but provides excellent casting properties for intricate components. Your choice between aluminium and zinc alloy will depend on balancing budget constraints with the need for precision in your product design.

Common Applications and Industries

Aluminium alloy is widely used in aerospace, automotive, and construction industries due to its lightweight strength and corrosion resistance, making it ideal for aircraft frames, car parts, and building facades. Zinc alloy finds common applications in die-casting for intricate components in electronics, automotive fittings, and household hardware, valued for its excellent dimensional stability and cost-effectiveness. Both alloys serve critical roles in manufacturing but differ in properties that influence their suitability for specific industrial applications.

Environmental Impact and Recyclability

Aluminium alloy offers significant environmental benefits due to its high recyclability rate, consuming only about 5% of the energy required for primary production, which reduces greenhouse gas emissions. Zinc alloy, while also recyclable, typically demands more energy during recycling and has a slightly lower recycling efficiency compared to aluminium. The sustainability of aluminium alloys is further enhanced by their widespread recycling infrastructure and minimal impact on natural resources.

Choosing Between Aluminium Alloy and Zinc Alloy

Aluminium alloy offers lightweight strength, excellent corrosion resistance, and superior thermal conductivity, making it ideal for aerospace, automotive, and marine applications. Zinc alloy provides high load-bearing capacity, superior castability, and cost-effectiveness, commonly used in die-casting for intricate components and consumer hardware. Selecting between aluminium and zinc alloys depends on the required mechanical properties, environmental exposure, and budget constraints for the intended industrial application.

Aluminium Alloy vs Zinc Alloy Infographic

libmatt.com

libmatt.com