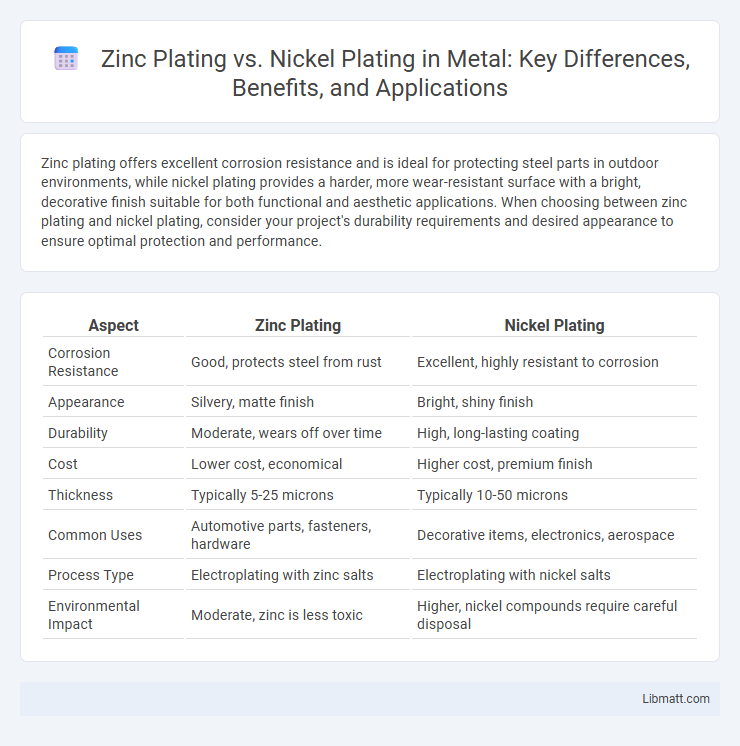

Zinc plating offers excellent corrosion resistance and is ideal for protecting steel parts in outdoor environments, while nickel plating provides a harder, more wear-resistant surface with a bright, decorative finish suitable for both functional and aesthetic applications. When choosing between zinc plating and nickel plating, consider your project's durability requirements and desired appearance to ensure optimal protection and performance.

Table of Comparison

| Aspect | Zinc Plating | Nickel Plating |

|---|---|---|

| Corrosion Resistance | Good, protects steel from rust | Excellent, highly resistant to corrosion |

| Appearance | Silvery, matte finish | Bright, shiny finish |

| Durability | Moderate, wears off over time | High, long-lasting coating |

| Cost | Lower cost, economical | Higher cost, premium finish |

| Thickness | Typically 5-25 microns | Typically 10-50 microns |

| Common Uses | Automotive parts, fasteners, hardware | Decorative items, electronics, aerospace |

| Process Type | Electroplating with zinc salts | Electroplating with nickel salts |

| Environmental Impact | Moderate, zinc is less toxic | Higher, nickel compounds require careful disposal |

Introduction to Metal Plating: Zinc vs Nickel

Zinc plating offers excellent corrosion resistance by forming a protective barrier and sacrificial layer on steel surfaces, making it ideal for automotive and construction applications. Nickel plating provides superior wear resistance, enhanced hardness, and an attractive finish, commonly used in electronics, aerospace, and decorative industries. Both metals enhance durability and aesthetics but differ significantly in protective qualities, cost, and suitable environments.

Overview of Zinc Plating

Zinc plating involves applying a thin layer of zinc onto the surface of metal parts to provide corrosion resistance and improve durability. This electrochemical process creates a sacrificial barrier that prevents rust by corroding before the underlying steel. Zinc plating is commonly used in automotive, construction, and hardware industries due to its cost-effectiveness and strong protective properties.

Overview of Nickel Plating

Nickel plating provides a durable, corrosion-resistant coating commonly used in automotive, aerospace, and electronics industries to enhance metal surfaces. Its excellent hardness and wear resistance properties make it ideal for components requiring extended lifespan and aesthetic appeal. Compared to zinc plating, nickel plating offers superior resistance to oxidation and maintains a bright, polished finish under harsh environmental conditions.

Key Differences Between Zinc and Nickel Plating

Zinc plating offers excellent corrosion resistance through sacrificial protection, making it ideal for outdoor and automotive parts, while nickel plating provides superior hardness and wear resistance for decorative and industrial applications. Zinc typically forms a dull silvery finish and is more cost-effective, whereas nickel produces a bright, shiny, and more durable surface. Your choice depends on whether corrosion resistance or aesthetic appeal and surface hardness are the primary requirements.

Corrosion Resistance Comparison

Zinc plating offers excellent corrosion resistance by providing a sacrificial layer that protects steel from rust, making it ideal for outdoor and industrial applications. Nickel plating provides superior corrosion resistance in harsher environments due to its dense, hard, and chemically stable surface, often used in automotive and marine industries. Zinc plating tends to be more cost-effective with good protection, while nickel plating delivers longer-lasting durability against oxidation and chemical exposure.

Surface Appearance and Finish Quality

Zinc plating offers a bright, matte to semi-gloss finish that provides excellent corrosion resistance, making it ideal for industrial applications where durability is key. Nickel plating delivers a smooth, shiny, and highly reflective surface, enhancing both aesthetic appeal and wear resistance, often preferred in decorative and high-performance settings. Your choice between zinc and nickel plating depends on whether you prioritize protective functionality with a subtle finish or a polished, high-gloss appearance.

Durability and Wear Protection

Zinc plating offers excellent corrosion resistance by forming a protective barrier against rust, making it ideal for outdoor and automotive applications, but it is generally softer and less wear-resistant than nickel plating. Nickel plating provides superior hardness and wear protection, enhancing the longevity of components exposed to friction and mechanical stress, commonly used in industrial machinery and tools. Both coatings improve durability, yet nickel plating excels in abrasion resistance while zinc plating is favored for cost-effective corrosion protection.

Cost Analysis: Zinc vs Nickel Plating

Zinc plating generally offers a more cost-effective solution compared to nickel plating, with lower material and processing expenses suitable for large-scale applications. Nickel plating, while more expensive due to higher material costs and complex processes, provides superior corrosion resistance and aesthetic appeal, justifying its use in high-end or precision industries. Evaluating total cost includes considering longevity and performance benefits where nickel plating can reduce maintenance and replacement expenses over time.

Common Applications in Industry

Zinc plating is widely used in automotive, construction, and manufacturing industries for corrosion resistance on steel parts, fasteners, and machinery components. Nickel plating is favored in aerospace, electronics, and decorative applications for its superior hardness, wear resistance, and aesthetic appeal on tools, connectors, and jewelry. Both coatings enhance metal durability but serve distinct industry needs based on environmental exposure and mechanical requirements.

Choosing the Right Plating for Your Needs

Zinc plating provides excellent corrosion resistance and is cost-effective for protecting steel parts in automotive and construction industries, while nickel plating offers superior hardness, wear resistance, and a decorative finish ideal for electronics and aerospace components. Your choice depends on the desired balance between protection, appearance, and durability, with zinc suited for economical rust prevention and nickel favored for longer-lasting, high-performance applications. Consider factors like environmental exposure, mechanical stress, and aesthetic requirements to select the plating that best meets your specific needs.

Zinc Plating vs Nickel Plating Infographic

libmatt.com

libmatt.com