Aluminum offers a lightweight alternative to steel, making it ideal for applications where reducing weight is crucial without sacrificing corrosion resistance. Steel provides superior strength and durability, making it suitable for heavy-duty structures and environments demanding high impact resistance.

Table of Comparison

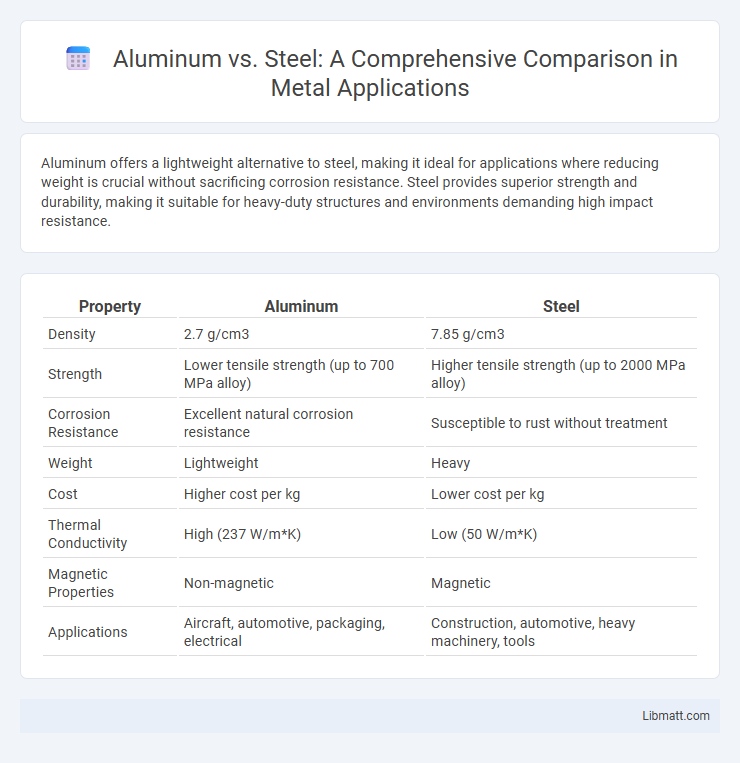

| Property | Aluminum | Steel |

|---|---|---|

| Density | 2.7 g/cm3 | 7.85 g/cm3 |

| Strength | Lower tensile strength (up to 700 MPa alloy) | Higher tensile strength (up to 2000 MPa alloy) |

| Corrosion Resistance | Excellent natural corrosion resistance | Susceptible to rust without treatment |

| Weight | Lightweight | Heavy |

| Cost | Higher cost per kg | Lower cost per kg |

| Thermal Conductivity | High (237 W/m*K) | Low (50 W/m*K) |

| Magnetic Properties | Non-magnetic | Magnetic |

| Applications | Aircraft, automotive, packaging, electrical | Construction, automotive, heavy machinery, tools |

Introduction to Aluminum and Steel

Aluminum, a lightweight metal known for its excellent corrosion resistance and high strength-to-weight ratio, is widely used in aerospace, automotive, and construction industries. Steel, an alloy primarily composed of iron and carbon, offers superior strength, durability, and versatility, making it a staple material in infrastructure, machinery, and transportation. Both metals serve critical roles across various applications, with aluminum favored for reducing weight and steel preferred for structural integrity.

Key Properties Comparison

Aluminum offers a superior strength-to-weight ratio compared to steel, making it ideal for applications requiring lightweight materials without compromising durability. Steel provides higher tensile strength and better impact resistance, which makes it suitable for structural and heavy-duty uses. Corrosion resistance in aluminum exceeds that of most steel types, especially without protective coatings, enhancing its performance in marine and outdoor environments.

Strength and Durability

Aluminum offers a favorable strength-to-weight ratio, making it ideal for applications requiring lightweight materials without compromising durability. Steel, however, surpasses aluminum in tensile strength and impact resistance, providing superior structural integrity in heavy-duty uses. The choice between aluminum and steel depends on the specific strength requirements and environmental conditions of the project.

Weight Differences

Aluminum is significantly lighter than steel, often weighing about one-third as much, which makes it ideal for applications where reducing weight is crucial, such as in automotive or aerospace industries. The lower density of aluminum contributes to improved fuel efficiency and easier handling without compromising structural integrity. Understanding these weight differences helps you make informed decisions when selecting materials for projects requiring strength-to-weight balance.

Corrosion Resistance

Aluminum offers superior corrosion resistance compared to steel due to its natural oxide layer that protects the metal from environmental elements. Steel requires protective coatings like galvanization or paint to prevent rust and deterioration when exposed to moisture and oxygen. In marine and outdoor applications, aluminum's resistance to oxidation contributes to longer lifespan and lower maintenance costs.

Cost and Value Analysis

Aluminum typically costs more upfront than steel due to its lightweight properties and corrosion resistance, offering long-term savings through reduced maintenance and transportation expenses. Steel provides higher strength at a lower initial price, making it a cost-effective option for heavy-duty applications where weight is less critical. When assessing your project, consider the total lifecycle value, including installation, durability, and potential energy savings, to determine the best choice between aluminum and steel.

Applications and Industries

Aluminum is widely used in aerospace, automotive, and packaging industries due to its lightweight and corrosion-resistant properties, making it ideal for fuel-efficient vehicles, aircraft components, and food containers. Steel dominates construction, infrastructure, and heavy machinery sectors because of its superior strength, durability, and cost-effectiveness for buildings, bridges, and industrial equipment. Both metals serve critical roles, with aluminum preferred for applications requiring weight reduction and steel chosen for structural integrity and load-bearing requirements.

Environmental Impact

Aluminum production generally has a higher initial environmental impact due to energy-intensive smelting processes, but its lightweight properties contribute to significant long-term reductions in carbon emissions, especially in transportation applications. Steel production emits more CO2 because of its reliance on coal in blast furnaces, yet it is highly recyclable, with recycled steel requiring substantially less energy than primary production. Your choice between aluminum and steel should consider the full lifecycle impact, including extraction, manufacturing, usage, and recycling to minimize environmental footprint.

Machinability and Workability

Aluminum offers superior machinability compared to steel due to its lower density and softer composition, which allows for faster cutting speeds and reduced tool wear. Its excellent workability enables easy forming, bending, and welding, making it ideal for complex shapes and lightweight applications. Steel, although harder to machine, provides higher strength and durability, but often requires specialized tooling and slower processing to maintain precision.

Choosing Between Aluminum and Steel

Choosing between aluminum and steel depends on the specific application's weight, strength, and corrosion resistance requirements. Aluminum offers superior corrosion resistance and a lighter weight, making it ideal for aerospace, automotive, and marine industries where reducing weight is critical. Steel provides higher tensile strength and durability at a lower cost, making it preferable for construction, heavy machinery, and infrastructure projects requiring robust structural support.

aluminum vs steel Infographic

libmatt.com

libmatt.com