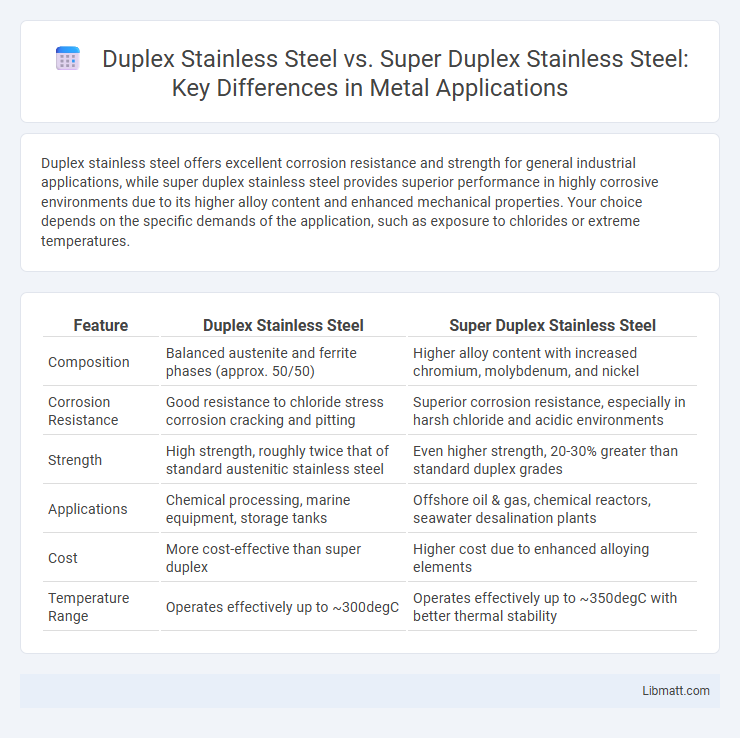

Duplex stainless steel offers excellent corrosion resistance and strength for general industrial applications, while super duplex stainless steel provides superior performance in highly corrosive environments due to its higher alloy content and enhanced mechanical properties. Your choice depends on the specific demands of the application, such as exposure to chlorides or extreme temperatures.

Table of Comparison

| Feature | Duplex Stainless Steel | Super Duplex Stainless Steel |

|---|---|---|

| Composition | Balanced austenite and ferrite phases (approx. 50/50) | Higher alloy content with increased chromium, molybdenum, and nickel |

| Corrosion Resistance | Good resistance to chloride stress corrosion cracking and pitting | Superior corrosion resistance, especially in harsh chloride and acidic environments |

| Strength | High strength, roughly twice that of standard austenitic stainless steel | Even higher strength, 20-30% greater than standard duplex grades |

| Applications | Chemical processing, marine equipment, storage tanks | Offshore oil & gas, chemical reactors, seawater desalination plants |

| Cost | More cost-effective than super duplex | Higher cost due to enhanced alloying elements |

| Temperature Range | Operates effectively up to ~300degC | Operates effectively up to ~350degC with better thermal stability |

Introduction to Duplex and Super Duplex Stainless Steels

Duplex stainless steel combines austenitic and ferritic structures, offering enhanced strength, corrosion resistance, and toughness ideal for industrial applications in harsh environments. Super duplex stainless steel contains higher levels of chromium, molybdenum, and nitrogen, providing superior resistance to pitting, crevice corrosion, and stress corrosion cracking. Your selection between duplex and super duplex stainless steel depends on specific performance requirements in aggressive chemical or marine conditions.

Chemical Composition Differences

Duplex stainless steel typically contains 18-22% chromium, 4-6% nickel, and 2.5-3.5% molybdenum, providing balanced corrosion resistance and strength. Super duplex stainless steel features higher chromium (22-25%), nickel (5-7%), and molybdenum (3-5%) content, enhancing its resistance to chloride stress corrosion and pitting. Your choice depends on the required durability and exposure conditions, with super duplex offering superior performance in aggressive environments.

Microstructure Comparison

Duplex stainless steel features a balanced microstructure of approximately 50% austenite and 50% ferrite, providing excellent corrosion resistance and mechanical strength. Super duplex stainless steel enhances this by increasing the ferrite content to around 60-70%, resulting in superior resistance to chloride stress corrosion cracking and improved pitting resistance. Understanding the microstructure differences allows you to select the optimal stainless steel type for demanding environments requiring enhanced durability and longevity.

Mechanical Properties Overview

Duplex stainless steel exhibits a balanced microstructure of approximately 50% ferrite and 50% austenite, offering high tensile strength around 620-850 MPa and superior toughness compared to standard austenitic stainless steels. Super duplex stainless steel enhances these properties with higher chromium (24-26%) and molybdenum (3-5%) content, achieving tensile strengths over 850 MPa and improved resistance to stress corrosion cracking. The increased yield strength and improved fatigue resistance of super duplex grades make them ideal for demanding applications in the oil and gas industry and chemical processing.

Corrosion Resistance Analysis

Duplex stainless steel offers excellent corrosion resistance with a balanced microstructure of austenite and ferrite, making it highly effective against stress corrosion cracking and pitting in chloride-rich environments. Super duplex stainless steel enhances this resistance further by increasing the chromium, molybdenum, and nitrogen content, providing superior protection against localized corrosion and sulfide stress cracking, especially in aggressive marine and chemical conditions. The improved phase balance and alloy composition in super duplex grades result in significantly higher pitting resistance equivalent numbers (PREN), ensuring longer service life in harsh environments.

Common Applications and Industries

Duplex stainless steel is commonly used in chemical processing, oil and gas, and marine industries due to its excellent corrosion resistance and strength, ideal for heat exchangers, piping systems, and storage tanks. Super duplex stainless steel finds applications in more demanding environments such as offshore platforms, desalination plants, and pharmaceutical equipment, where higher resistance to stress corrosion cracking and chloride-induced corrosion is critical. Your selection between these materials should consider the specific environmental challenges and mechanical requirements of your industry to ensure optimal performance and longevity.

Weldability and Fabrication

Duplex stainless steel offers excellent weldability with reduced risk of hot cracking due to its balanced ferrite-austenite microstructure, making it suitable for standard fabrication processes. Super duplex stainless steel, containing higher chromium, molybdenum, and nitrogen levels, requires precise welding parameters and pre/post-weld heat treatments to avoid sensitization and maintain corrosion resistance. Both materials demand skilled fabrication techniques, but super duplex grades typically present more challenges due to their increased hardness and potential for embrittlement during welding.

Cost and Availability

Duplex stainless steel generally offers lower cost and greater availability compared to super duplex stainless steel, making it a more economical option for many industrial applications. Super duplex stainless steel, with its higher nickel and molybdenum content, commands a premium price due to enhanced corrosion resistance and mechanical strength. Availability of super duplex grades is more limited globally, leading to longer lead times and higher procurement expenses.

Standards and Grades

Duplex stainless steel typically conforms to standards such as ASTM A240 and A182, with common grades including UNS S31803 and S32205, offering balanced corrosion resistance and strength. Super duplex stainless steel meets more stringent criteria, often adhering to ASTM A789 and A815 standards, with prominent grades like UNS S32750 and S32760, characterized by higher chromium, molybdenum, and nitrogen content for enhanced pitting and crevice corrosion resistance. The selection between duplex and super duplex stainless steel is guided by specific service conditions and required corrosion allowances defined within these standards.

Choosing Between Duplex and Super Duplex Stainless Steel

Choosing between duplex and super duplex stainless steel depends on the specific corrosion resistance and strength requirements of your project. Duplex stainless steel offers good resistance to stress corrosion cracking and higher strength than austenitic stainless steels, while super duplex stainless steel provides enhanced resistance to pitting, crevice corrosion, and chloride environments, making it ideal for harsher conditions. Your selection should consider factors like chloride exposure, mechanical stress, and cost to optimize performance and durability.

Duplex stainless steel vs super duplex stainless steel Infographic

libmatt.com

libmatt.com