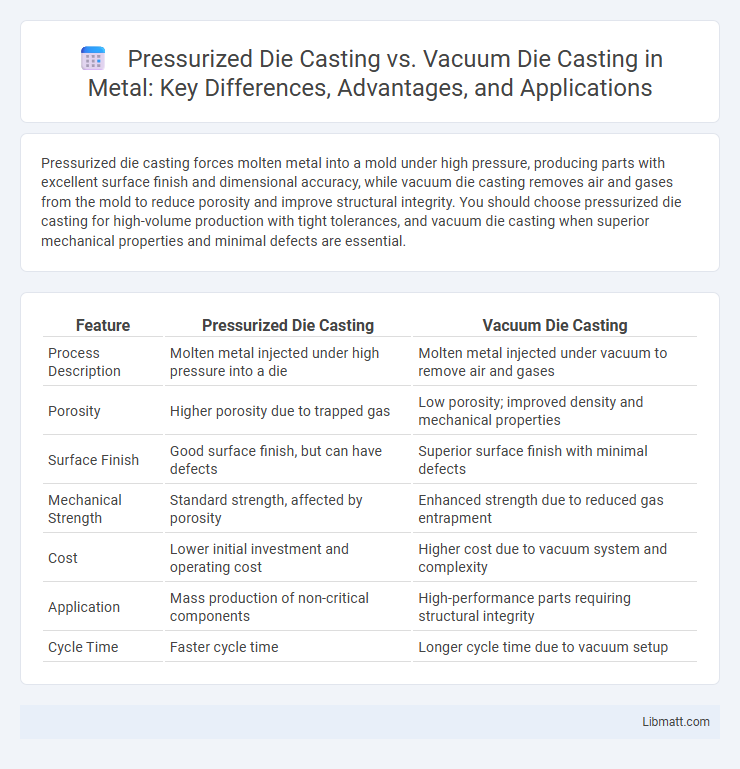

Pressurized die casting forces molten metal into a mold under high pressure, producing parts with excellent surface finish and dimensional accuracy, while vacuum die casting removes air and gases from the mold to reduce porosity and improve structural integrity. You should choose pressurized die casting for high-volume production with tight tolerances, and vacuum die casting when superior mechanical properties and minimal defects are essential.

Table of Comparison

| Feature | Pressurized Die Casting | Vacuum Die Casting |

|---|---|---|

| Process Description | Molten metal injected under high pressure into a die | Molten metal injected under vacuum to remove air and gases |

| Porosity | Higher porosity due to trapped gas | Low porosity; improved density and mechanical properties |

| Surface Finish | Good surface finish, but can have defects | Superior surface finish with minimal defects |

| Mechanical Strength | Standard strength, affected by porosity | Enhanced strength due to reduced gas entrapment |

| Cost | Lower initial investment and operating cost | Higher cost due to vacuum system and complexity |

| Application | Mass production of non-critical components | High-performance parts requiring structural integrity |

| Cycle Time | Faster cycle time | Longer cycle time due to vacuum setup |

Introduction to Die Casting Methods

Pressurized die casting uses high-pressure to force molten metal into a die, producing parts with excellent surface finish and dimensional accuracy. Vacuum die casting removes air and gases from the die before injection, reducing porosity and improving mechanical properties, especially for aerospace and automotive components. Both methods optimize metal flow but differ in pressure application and gas management to meet specific quality and performance requirements.

Overview of Pressurized Die Casting

Pressurized die casting, also known as high-pressure die casting, involves injecting molten metal into a mold cavity at extremely high pressure, resulting in precise, dense, and complex metal parts. This method is widely used for producing components with excellent surface finish and dimensional accuracy, commonly applied in automotive and aerospace industries. Your manufacturing process benefits from pressurized die casting when high-volume production of lightweight, intricately shaped metal parts with consistent quality is required.

Overview of Vacuum Die Casting

Vacuum die casting involves creating a low-pressure environment to reduce air entrapment and minimize porosity in metal castings, resulting in higher structural integrity and superior surface finish. This process is ideal for complex components requiring enhanced mechanical properties, such as automotive and aerospace parts. Compared to pressurized die casting, vacuum die casting significantly improves casting quality by eliminating gas-related defects and improving material density.

Key Differences Between Pressurized and Vacuum Die Casting

Pressurized die casting forces molten metal into a mold using high pressure, resulting in high production speed and excellent dimensional accuracy, while vacuum die casting uses a vacuum to remove air and gases, reducing porosity and enhancing mechanical strength and surface finish. Pressurized die casting is ideal for high-volume production of complex parts with consistent quality, whereas vacuum die casting suits applications requiring superior structural integrity and minimal defects. The main distinctions lie in the methods of mold filling and gas removal, which directly influence the quality, porosity content, and performance characteristics of the final cast components.

Material Compatibility in Both Processes

Pressurized die casting supports a wide range of non-ferrous metals, including aluminum, zinc, and magnesium, offering versatility for high-volume production with good mechanical properties. Vacuum die casting excels in processing aluminum alloys by significantly reducing gas porosity and improving structural integrity, making it ideal for applications requiring superior surface finish and strength. Both methods enhance material compatibility through optimized pressure application, but vacuum die casting particularly benefits alloys sensitive to oxidation and gas entrapment.

Surface Finish and Dimensional Accuracy

Pressurized die casting produces components with good surface finish but often contains micro-porosity, which can affect the overall smoothness and strength. Vacuum die casting significantly enhances surface finish by eliminating gas porosity, resulting in smoother surfaces and improved aesthetic quality. Your choice between these methods should consider that vacuum die casting offers superior dimensional accuracy due to reduced defects and shrinkage.

Strength and Mechanical Properties of Cast Parts

Pressurized die casting produces cast parts with higher density and fewer porosities, resulting in superior tensile strength and improved mechanical properties compared to traditional methods. Vacuum die casting further minimizes gas entrapment and shrinkage defects by creating a low-pressure environment, enhancing fatigue resistance and overall mechanical integrity. Both techniques improve casting quality, but vacuum die casting is especially advantageous for critical components requiring exceptional strength and longevity.

Typical Applications and Industries

Pressurized die casting is widely used in automotive, aerospace, and consumer electronics industries for manufacturing complex, high-strength components such as engine blocks, housings, and structural parts. Vacuum die casting is preferred in aerospace and medical device sectors for producing corrosion-resistant, high-integrity parts with reduced porosity, like turbine blades and surgical instruments. Your choice between these methods depends on the required material properties and application-specific quality standards.

Cost Considerations and Production Efficiency

Pressurized die casting typically offers lower upfront costs due to simpler equipment and faster cycle times, making it ideal for high-volume production runs seeking cost efficiency. Vacuum die casting, while involving higher initial investment and operational expenses, enhances product quality by reducing porosity and improving mechanical properties, which can decrease long-term costs related to defects and rework. Your choice between these methods should balance immediate cost savings with production efficiency and the quality demands of your final product.

Choosing the Right Method for Your Project

Selecting between pressurized die casting and vacuum die casting depends on your project's requirements for precision, surface quality, and material properties. Pressurized die casting offers high production rates and cost efficiency for complex parts, while vacuum die casting reduces porosity and improves structural integrity, ideal for aerospace and automotive applications. Understanding the trade-offs in strength, finish, and production volume helps ensure your casting method aligns perfectly with your project goals.

pressurized die casting vs vacuum die casting Infographic

libmatt.com

libmatt.com