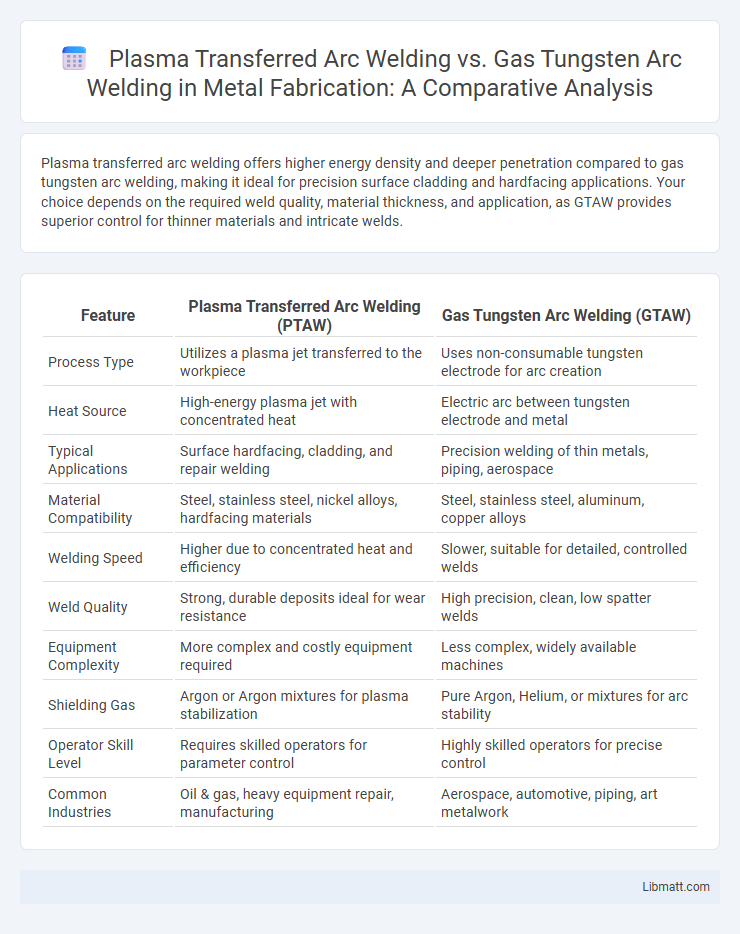

Plasma transferred arc welding offers higher energy density and deeper penetration compared to gas tungsten arc welding, making it ideal for precision surface cladding and hardfacing applications. Your choice depends on the required weld quality, material thickness, and application, as GTAW provides superior control for thinner materials and intricate welds.

Table of Comparison

| Feature | Plasma Transferred Arc Welding (PTAW) | Gas Tungsten Arc Welding (GTAW) |

|---|---|---|

| Process Type | Utilizes a plasma jet transferred to the workpiece | Uses non-consumable tungsten electrode for arc creation |

| Heat Source | High-energy plasma jet with concentrated heat | Electric arc between tungsten electrode and metal |

| Typical Applications | Surface hardfacing, cladding, and repair welding | Precision welding of thin metals, piping, aerospace |

| Material Compatibility | Steel, stainless steel, nickel alloys, hardfacing materials | Steel, stainless steel, aluminum, copper alloys |

| Welding Speed | Higher due to concentrated heat and efficiency | Slower, suitable for detailed, controlled welds |

| Weld Quality | Strong, durable deposits ideal for wear resistance | High precision, clean, low spatter welds |

| Equipment Complexity | More complex and costly equipment required | Less complex, widely available machines |

| Shielding Gas | Argon or Argon mixtures for plasma stabilization | Pure Argon, Helium, or mixtures for arc stability |

| Operator Skill Level | Requires skilled operators for parameter control | Highly skilled operators for precise control |

| Common Industries | Oil & gas, heavy equipment repair, manufacturing | Aerospace, automotive, piping, art metalwork |

Introduction to Plasma Transferred Arc Welding and Gas Tungsten Arc Welding

Plasma Transferred Arc Welding (PTAW) utilizes a plasma arc to create a high-energy heat source for precision welding and metal cladding, often applied in hardfacing and repair applications where strong, wear-resistant surfaces are essential. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, employs a non-consumable tungsten electrode and inert gas shielding to produce clean, high-quality welds, ideal for thin materials and critical joints in aerospace, automotive, and piping industries. Your choice between PTAW and GTAW depends on factors like material thickness, weld quality requirements, and the specific welding environment.

Fundamental Principles of Each Welding Process

Plasma transferred arc welding (PTAW) utilizes a constricted plasma arc between a non-consumable electrode and the workpiece, creating a highly focused heat source for precise metal deposition and enhanced penetration control. Gas tungsten arc welding (GTAW), also known as TIG welding, employs a non-consumable tungsten electrode to produce an arc that melts the base metal without filler material reliance, offering superior weld quality and control over the weld pool. The fundamental difference lies in PTAW's use of a transferred arc for deeper penetration and higher deposition rates, while GTAW relies on a non-transferred arc for cleaner, more controlled welds on thin materials.

Equipment and Setup Requirements

Plasma transferred arc welding (PTAW) requires specialized equipment including a plasma torch, a separate powder feed system for filler material, and a DC power source capable of high current levels, making its setup more complex and costly than gas tungsten arc welding (GTAW). GTAW relies on a simpler tungsten electrode, inert gas supply typically argon or helium, and an AC or DC power source, which is widely available and easier to configure. The precise control and higher deposition rates of PTAW demand meticulous setup and calibration, whereas GTAW offers flexibility and ease of use for thin materials and intricate welds.

Process Parameters and Control

Plasma transferred arc welding (PTAW) offers precise control over welding parameters such as current, voltage, and plasma gas flow rate, enabling stable arc characteristics and deep penetration suitable for hardfacing applications. Gas tungsten arc welding (GTAW) allows for meticulous adjustment of current type, amperage, and shielding gas composition, providing superior control for thin materials and intricate welds. Your choice between PTAW and GTAW depends on the required heat input control and the specific welding process parameters critical for the application's metallurgical properties.

Types of Materials Suitable for Each Method

Plasma transferred arc welding (PTAW) is highly effective for welding hardfacing materials, corrosion-resistant alloys, and dissimilar metals, including stainless steel, cobalt, and nickel-based alloys. Gas tungsten arc welding (GTAW), also known as TIG welding, excels in welding thin sections of stainless steel, aluminum, magnesium, and other non-ferrous metals due to its precise heat control and clean welds. Each method offers specific advantages depending on material thickness, alloy composition, and desired weld characteristics.

Welding Speed and Efficiency Comparison

Plasma transferred arc welding (PTAW) offers higher welding speeds and greater deposition rates compared to gas tungsten arc welding (GTAW), making it more efficient for thick material applications. PTAW achieves faster melting and deeper penetration through a constricted plasma arc, reducing overall welding time and energy consumption. GTAW, while providing superior weld quality and precision for thin materials, generally results in slower weld speeds and lower throughput.

Quality and Characteristics of Welds

Plasma transferred arc welding (PTAW) produces welds with superior penetration and minimal dilution, resulting in stronger and more wear-resistant joints compared to gas tungsten arc welding (GTAW). GTAW offers excellent control over weld bead quality and produces clean, precise, and high-purity welds ideal for thin materials and critical applications. Both processes yield high-quality welds, but PTAW is preferred for heavy-duty coatings and repair welding, while GTAW excels in applications requiring fine, defect-free welds.

Common Applications in Industry

Plasma transferred arc welding (PTAW) is commonly used for hardfacing, cladding, and repair applications in industries such as aerospace, aerospace, and heavy equipment manufacturing due to its precise control and deep penetration. Gas tungsten arc welding (GTAW), also known as TIG welding, is preferred in industries requiring high-quality, precise welds like aerospace, automotive, and nuclear power, especially for joining stainless steel, aluminum, and other non-ferrous metals. Both methods are critical for producing durable, corrosion-resistant welds in demanding industrial environments.

Advantages and Limitations of Each Technique

Plasma transferred arc welding (PTAW) offers high deposition rates and excellent control over bead shape, making it ideal for hardfacing and cladding applications where precision and wear resistance are crucial. Gas tungsten arc welding (GTAW), also known as TIG welding, provides superior weld quality with minimal spatter and is best suited for thin materials and intricate joints, offering exceptional control over heat input and weld pool. Your choice between PTAW and GTAW should consider the specific requirements of material thickness, welding speed, and desired weld properties to optimize performance and cost-effectiveness.

Cost Considerations and Economic Impact

Plasma transferred arc welding (PTAW) typically incurs higher initial equipment costs compared to gas tungsten arc welding (GTAW), but offers greater deposition rates and productivity, potentially lowering labor expenses over time. GTAW remains cost-effective for precision work and thin materials due to lower consumable costs and simpler setup requirements, benefiting operations with less demanding volume needs. Your choice between PTAW and GTAW should factor in long-term economic impacts, considering project scale, material thickness, and required weld quality.

Plasma transferred arc welding vs gas tungsten arc welding Infographic

libmatt.com

libmatt.com