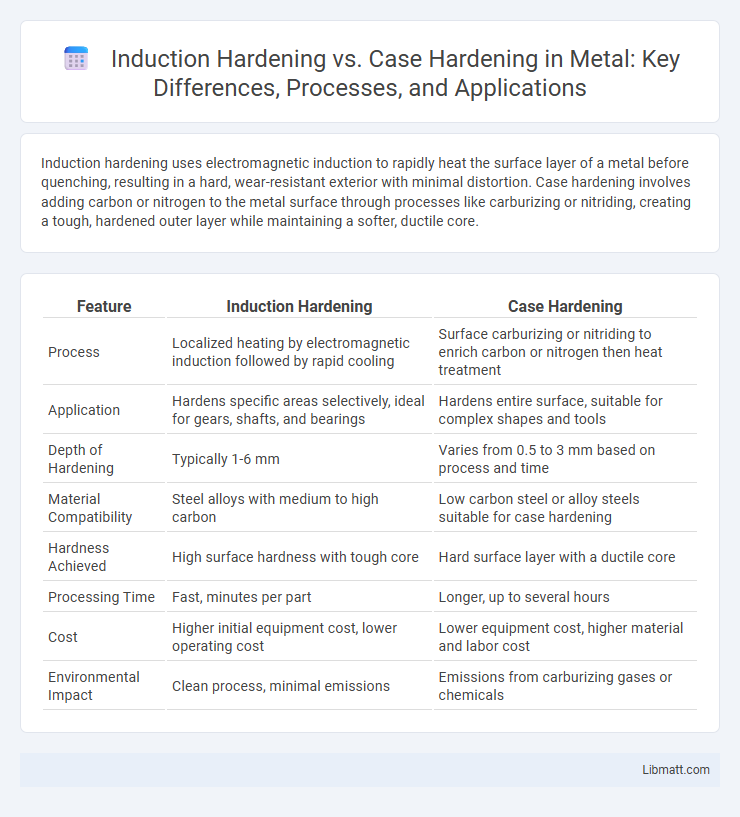

Induction hardening uses electromagnetic induction to rapidly heat the surface layer of a metal before quenching, resulting in a hard, wear-resistant exterior with minimal distortion. Case hardening involves adding carbon or nitrogen to the metal surface through processes like carburizing or nitriding, creating a tough, hardened outer layer while maintaining a softer, ductile core.

Table of Comparison

| Feature | Induction Hardening | Case Hardening |

|---|---|---|

| Process | Localized heating by electromagnetic induction followed by rapid cooling | Surface carburizing or nitriding to enrich carbon or nitrogen then heat treatment |

| Application | Hardens specific areas selectively, ideal for gears, shafts, and bearings | Hardens entire surface, suitable for complex shapes and tools |

| Depth of Hardening | Typically 1-6 mm | Varies from 0.5 to 3 mm based on process and time |

| Material Compatibility | Steel alloys with medium to high carbon | Low carbon steel or alloy steels suitable for case hardening |

| Hardness Achieved | High surface hardness with tough core | Hard surface layer with a ductile core |

| Processing Time | Fast, minutes per part | Longer, up to several hours |

| Cost | Higher initial equipment cost, lower operating cost | Lower equipment cost, higher material and labor cost |

| Environmental Impact | Clean process, minimal emissions | Emissions from carburizing gases or chemicals |

Introduction to Induction Hardening and Case Hardening

Induction hardening uses electromagnetic induction to rapidly heat and quench the surface of steel, producing a hardened layer with precise depth control and minimal distortion. Case hardening involves diffusing carbon or nitrogen into the metal surface through processes like carburizing or nitriding, creating a tough, wear-resistant outer layer while maintaining a ductile core. Both methods enhance surface hardness but differ in heat application, treatment time, and microstructural changes, making them suitable for diverse industrial applications.

Principles of Induction Hardening

Induction hardening employs electromagnetic induction to rapidly heat metal surfaces followed by immediate quenching, producing a hardened layer while retaining a tough core. This process allows precise control over the depth and pattern of hardening, enhancing wear resistance and fatigue strength in critical components. The localized heating minimizes distortion and avoids affecting the entire workpiece, making it ideal for gears, shafts, and bearings requiring high surface hardness.

Principles of Case Hardening

Case hardening involves enriching the surface layer of steel with carbon or nitrogen through processes like carburizing or nitriding, creating a hard, wear-resistant exterior while maintaining a tough core. This selective hardening enhances surface durability without compromising the material's overall strength. Your components benefit from increased fatigue resistance and improved lifespan through precise control of temperature and time during case hardening.

Key Differences Between Induction and Case Hardening

Induction hardening uses electromagnetic induction to heat the surface of a metal rapidly before quenching, resulting in a harder, wear-resistant outer layer while maintaining a tough core. Case hardening involves infusing elements like carbon or nitrogen into the metal surface at high temperatures, creating a hardened shell that improves surface durability without altering the core composition significantly. Your choice between these methods depends on factors like precision, depth of hardness, and production speed required for your specific application.

Material Suitability for Each Hardening Method

Induction hardening is ideal for steel alloys with medium to high carbon content, allowing selective surface hardening without affecting the core's toughness. Case hardening suits low carbon steels and alloys, enriching the surface with carbon or nitrogen to form a hardened outer layer while maintaining a ductile core. Both methods optimize mechanical properties based on material composition and intended application.

Process Steps: Induction vs. Case Hardening

Induction hardening involves rapidly heating the metal surface using electromagnetic induction followed by immediate quenching, resulting in a hardened outer layer with minimal distortion. Case hardening, also known as carburizing, adds carbon to the surface by heating the workpiece in a carbon-rich environment before quenching, creating a hardened case with a softer core. Both processes enhance surface hardness but differ significantly in heating method, carbon diffusion, and thermal cycle duration.

Advantages and Limitations of Induction Hardening

Induction hardening offers precise control, rapid heating, and localized hardening, reducing distortion and improving wear resistance on specific parts like gears or shafts. However, its limitations include higher initial equipment costs, complexity in processing irregular shapes, and restricted case depth compared to traditional case hardening methods. Your choice depends on the need for speed, precision, and minimal thermal impact versus deeper, uniform surface hardening.

Advantages and Limitations of Case Hardening

Case hardening offers advantages such as enhanced surface hardness and improved wear resistance while maintaining a tougher, more ductile core, ideal for components subjected to high stress and impact. It provides better dimensional stability and is suitable for complex shapes, but limitations include longer processing times, potential distortion, and limited effective depth compared to induction hardening. This method is less energy-efficient and may require subsequent machining or finishing to achieve precise tolerances.

Common Industrial Applications

Induction hardening is widely used in the automotive and aerospace industries for components such as gears, shafts, and camshafts, offering precise control over surface hardness and minimal distortion. Case hardening finds common applications in manufacturing tools, ball bearings, and heavy machinery parts, providing a tough surface layer while maintaining a ductile core. Your choice between these methods depends on the required depth of hardness, production speed, and component geometry.

Choosing the Right Hardening Technique for Your Needs

Induction hardening offers precise, localized surface hardening with minimal distortion, ideal for components requiring high wear resistance and fatigue strength. Case hardening, including carburizing and nitriding, provides a deeper hardened layer, enhancing core toughness while maintaining a tough interior, suitable for parts subjected to heavy loads. Selecting the right technique depends on your specific application requirements, such as depth of hardness, component geometry, and performance criteria.

Induction hardening vs case hardening Infographic

libmatt.com

libmatt.com