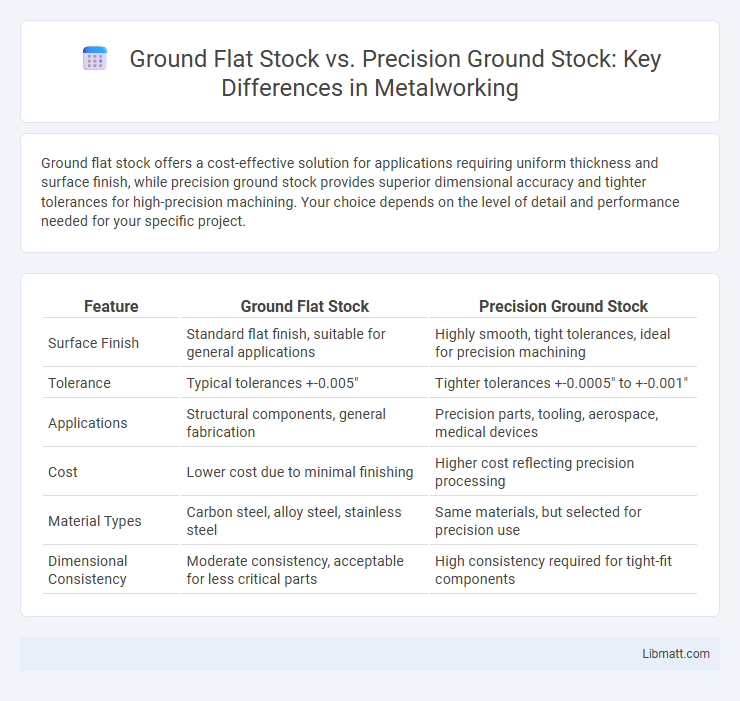

Ground flat stock offers a cost-effective solution for applications requiring uniform thickness and surface finish, while precision ground stock provides superior dimensional accuracy and tighter tolerances for high-precision machining. Your choice depends on the level of detail and performance needed for your specific project.

Table of Comparison

| Feature | Ground Flat Stock | Precision Ground Stock |

|---|---|---|

| Surface Finish | Standard flat finish, suitable for general applications | Highly smooth, tight tolerances, ideal for precision machining |

| Tolerance | Typical tolerances +-0.005" | Tighter tolerances +-0.0005" to +-0.001" |

| Applications | Structural components, general fabrication | Precision parts, tooling, aerospace, medical devices |

| Cost | Lower cost due to minimal finishing | Higher cost reflecting precision processing |

| Material Types | Carbon steel, alloy steel, stainless steel | Same materials, but selected for precision use |

| Dimensional Consistency | Moderate consistency, acceptable for less critical parts | High consistency required for tight-fit components |

Understanding Ground Flat Stock

Ground flat stock offers a cost-effective solution for applications where surface finish and dimensional accuracy requirements are moderate, making it ideal for general fabrication and structural components. Precision ground stock provides superior surface finish and tighter tolerances, essential for high-performance engineering parts demanding exact dimensions and smooth finishes. Understanding ground flat stock involves recognizing its balance of quality and affordability, while precision ground stock ensures optimal functionality in critical mechanical and industrial applications.

What Is Precision Ground Stock?

Precision Ground Stock refers to metal flat stock that has been ground to exact thickness and surface finish tolerances, ensuring superior dimensional accuracy compared to standard ground flat stock. It is commonly used in applications requiring tight tolerances and smooth finishes, such as in aerospace, automotive, and precision machining industries. Choosing Precision Ground Stock helps ensure Your parts meet stringent quality standards and reduces the need for secondary processing.

Key Differences Between Ground Flat Stock and Precision Ground Stock

Ground Flat Stock offers standard dimensional tolerances suitable for general applications, while Precision Ground Stock provides tighter tolerances and superior surface finishes essential for high-accuracy machining or tooling. Precision Ground Stock undergoes additional finishing processes, resulting in enhanced flatness and thickness control that meets stringent engineering specifications. Your choice depends on the required precision level and application demands, with precision stock preferred for critical components requiring exact dimensions.

Material Types and Composition

Ground Flat Stock typically consists of carbon steel or stainless steel with a uniform thickness, offering a balance of strength and machinability for general applications. Precision Ground Stock uses high-grade alloy steels or tool steels with carefully controlled composition and superior surface finish to meet stringent dimensional tolerances and enhanced mechanical properties. Your choice depends on the specific material performance and accuracy requirements of your project.

Manufacturing Processes Compared

Ground flat stock undergoes a standard grinding process that removes surface imperfections and achieves basic dimensional accuracy, making it suitable for general applications requiring flatness and smoothness. Precision ground stock involves a more refined grinding technique with tighter tolerances and finer surface finishes, often using specialized equipment to ensure consistent thickness and minimal variance. The manufacturing process for precision ground stock emphasizes accuracy and quality control, resulting in materials ideal for high-precision engineering and tooling applications.

Dimensional Tolerances and Surface Finishes

Ground flat stock offers standard dimensional tolerances typically around +-0.005 inches, suitable for general applications requiring uniform thickness and flatness, with surface finishes commonly ranging from 32 to 63 microinches Ra. Precision ground stock delivers tighter dimensional tolerances, often as precise as +-0.0002 inches, ideal for high-accuracy machining or assembly tasks demanding exact measurements and minimal variation. Your choice between the two depends on the necessary precision level and surface finish quality, where precision ground stock provides superior smoothness and consistency tailored for critical engineering requirements.

Applications in Industry

Ground flat stock is widely used in general manufacturing and fabrication processes requiring consistent thickness and surface finish, suitable for automotive parts, machinery bases, and structural components. Precision ground stock offers tighter dimensional tolerances and superior surface finishes, making it ideal for aerospace components, medical devices, and high-precision engineering applications where exact measurements are critical. Your choice between ground flat stock and precision ground stock depends on the specific industry demands for accuracy, surface quality, and performance requirements.

Cost Comparison and Value

Ground Flat Stock generally offers a more cost-effective solution for projects with less stringent tolerance requirements, providing a balance between quality and price. Precision Ground Stock, while more expensive, delivers superior dimensional accuracy and surface finish, reducing machining time and material waste--enhancing overall value for high-precision applications. Choosing the right option depends on Your specific needs, where investing in precision stock could lead to long-term savings through improved efficiency and reduced rework.

Choosing the Right Stock for Your Project

Ground flat stock offers versatility and cost-effectiveness for general machining and fabrication tasks, providing consistent thickness and smooth surfaces ideal for structural applications. Precision ground stock delivers tighter tolerances, superior flatness, and enhanced surface finish, making it essential for projects requiring exact dimensions and high-quality finishes. Selecting the right stock depends on your project's requirements for accuracy, surface quality, and budget constraints.

Expert Tips for Optimal Performance

Ground flat stock offers versatility and cost-effectiveness for general machining needs, while precision ground stock provides superior dimensional accuracy and surface finish essential for high-tolerance applications. Expert tips recommend choosing precision ground stock when consistent thickness and minimal variance are critical, especially in aerospace or automotive components. To optimize performance, maintaining proper storage conditions and using appropriate tooling can prevent deformation and preserve material integrity in both stock types.

Ground Flat Stock vs Precision Ground Stock Infographic

libmatt.com

libmatt.com