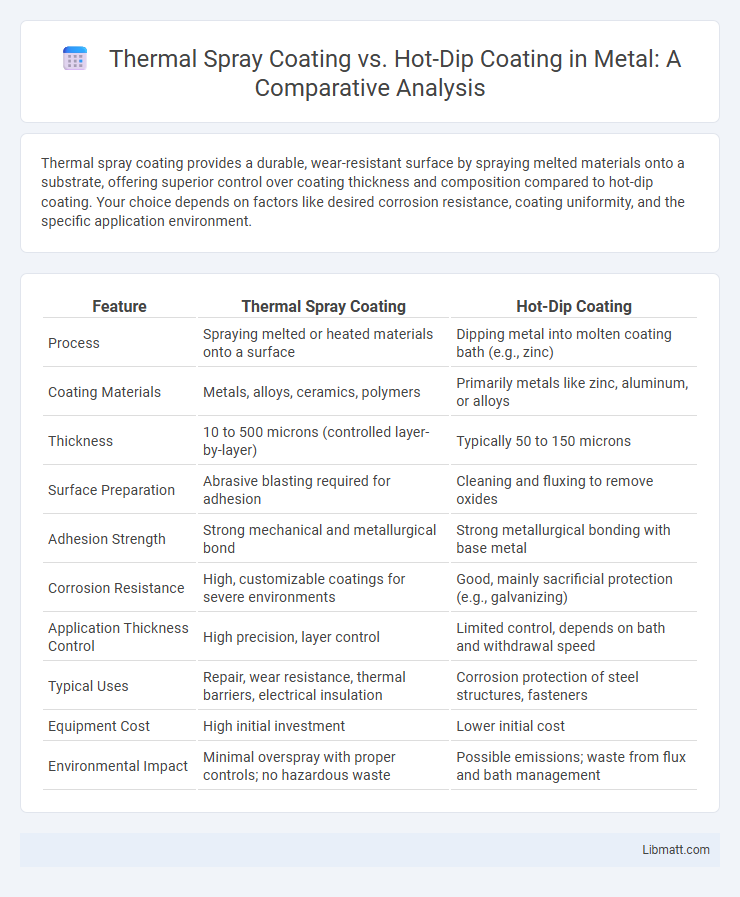

Thermal spray coating provides a durable, wear-resistant surface by spraying melted materials onto a substrate, offering superior control over coating thickness and composition compared to hot-dip coating. Your choice depends on factors like desired corrosion resistance, coating uniformity, and the specific application environment.

Table of Comparison

| Feature | Thermal Spray Coating | Hot-Dip Coating |

|---|---|---|

| Process | Spraying melted or heated materials onto a surface | Dipping metal into molten coating bath (e.g., zinc) |

| Coating Materials | Metals, alloys, ceramics, polymers | Primarily metals like zinc, aluminum, or alloys |

| Thickness | 10 to 500 microns (controlled layer-by-layer) | Typically 50 to 150 microns |

| Surface Preparation | Abrasive blasting required for adhesion | Cleaning and fluxing to remove oxides |

| Adhesion Strength | Strong mechanical and metallurgical bond | Strong metallurgical bonding with base metal |

| Corrosion Resistance | High, customizable coatings for severe environments | Good, mainly sacrificial protection (e.g., galvanizing) |

| Application Thickness Control | High precision, layer control | Limited control, depends on bath and withdrawal speed |

| Typical Uses | Repair, wear resistance, thermal barriers, electrical insulation | Corrosion protection of steel structures, fasteners |

| Equipment Cost | High initial investment | Lower initial cost |

| Environmental Impact | Minimal overspray with proper controls; no hazardous waste | Possible emissions; waste from flux and bath management |

Introduction to Thermal Spray and Hot-Dip Coating

Thermal spray coating involves depositing molten or semi-molten materials onto a surface to create a protective layer, enhancing wear resistance and corrosion protection. Hot-dip coating immerses substrates in molten metal, typically zinc, to form a metallurgical bond that provides durable corrosion resistance, especially for steel. Understanding these methods helps you choose the optimal coating based on application requirements, environmental conditions, and desired longevity.

Fundamentals of Thermal Spray Coating

Thermal spray coating involves the deposition of molten or semi-molten materials onto a substrate by propelling particles at high velocity, creating a dense, adherent layer with excellent wear and corrosion resistance. The process includes methods such as plasma spray, flame spray, and high-velocity oxy-fuel (HVOF), each differing in particle temperature and velocity to optimize coating properties. Thermal spray coatings typically achieve superior hardness and bond strength compared to hot-dip coatings, making them ideal for applications requiring precise control over coating thickness and composition.

Overview of Hot-Dip Coating Process

Hot-dip coating involves immersing metal components into a molten bath of zinc or other alloys, creating a robust and uniform protective layer against corrosion and wear. This process forms a metallurgical bond between the coating and the metal substrate, enhancing durability in harsh environments. Your choice between thermal spray coating and hot-dip coating depends on the specific application requirements, as hot-dip coating offers superior coverage for complex shapes and heavy-duty protection.

Key Material Compatibility and Substrate Choices

Thermal spray coating excels in compatibility with a wide range of materials including metals, ceramics, and polymers, making it ideal for substrates sensitive to heat or oxidation. Hot-dip coating is typically limited to ferrous and non-ferrous metals such as steel and aluminum, as it involves immersion in molten metal, which requires substrates to withstand high temperatures. Your choice depends on substrate sensitivity and desired coating performance, with thermal spray offering more versatility for complex or heat-sensitive materials.

Coating Thickness and Uniformity Comparison

Thermal spray coatings typically range from 50 to 1000 microns in thickness, offering precise control and superior uniformity due to the layer-by-layer application process. Hot-dip coatings, such as galvanizing, generally provide thicker coatings between 50 to 200 microns but often exhibit variable thickness and less uniform coverage, especially on complex geometries. The uniformity advantage of thermal spray coatings results in enhanced wear resistance and predictable performance, making it preferable for applications demanding consistent protective layers.

Corrosion Resistance Capabilities

Thermal spray coatings provide superior corrosion resistance due to their dense and uniform layers that effectively shield substrates from aggressive environments and enhance surface durability. Hot-dip coating, typically involving zinc or aluminum, offers robust sacrificial protection by forming a metallurgically bonded layer that corrodes preferentially, extending the lifespan of steel components. Both methods enhance corrosion resistance, but thermal spray coatings allow for tailored coatings with specific alloys or ceramics, while hot-dip coatings rely on the sacrificial action of the galvanized layer.

Adhesion Strength and Mechanical Performance

Thermal spray coating offers superior adhesion strength due to its mechanical bonding and metallurgical diffusion, resulting in enhanced mechanical performance under high-stress conditions. Hot-dip coating provides excellent corrosion resistance but may exhibit lower adhesion strength compared to thermal spray, potentially affecting durability in abrasive environments. Your choice between these coatings directly impacts the longevity and effectiveness of protective surfaces in industrial applications.

Application Areas and Industry Use Cases

Thermal spray coating finds extensive application in aerospace, automotive, and power generation industries, where it enhances wear resistance and thermal insulation on turbine blades, engine components, and exhaust systems. Hot-dip coating is predominantly used in construction, agriculture, and manufacturing sectors to provide corrosion protection on steel structures, pipelines, and fasteners through a zinc or aluminum layer. Your choice between these methods should align with the specific industry demands and operating environments to ensure optimal performance and durability.

Cost Analysis and Economic Considerations

Thermal spray coating generally involves higher initial equipment and operational costs compared to hot-dip coating, but it offers superior surface finish and precise thickness control which can reduce maintenance expenses over time. Hot-dip coating provides cost-effective large-scale corrosion protection and faster application cycles, making it economically advantageous for bulk coatings on steel structures. Analyzing total cost of ownership reveals thermal spray is suitable for high-performance, customized applications, whereas hot-dip coating excels in standard, large-volume industrial uses.

Environmental Impact and Sustainability Factors

Thermal spray coating generates less hazardous waste and typically involves lower energy consumption compared to hot-dip coating, which uses large volumes of molten metals and produces more toxic byproducts. Your choice of coating can significantly reduce environmental footprint, as thermal spray methods allow for precise application and minimize resource use. Sustainability factors favor thermal spray coatings due to their ability to extend component life without extensive chemical waste or heavy metal emissions common in hot-dip coatings.

Thermal spray coating vs hot-dip coating Infographic

libmatt.com

libmatt.com