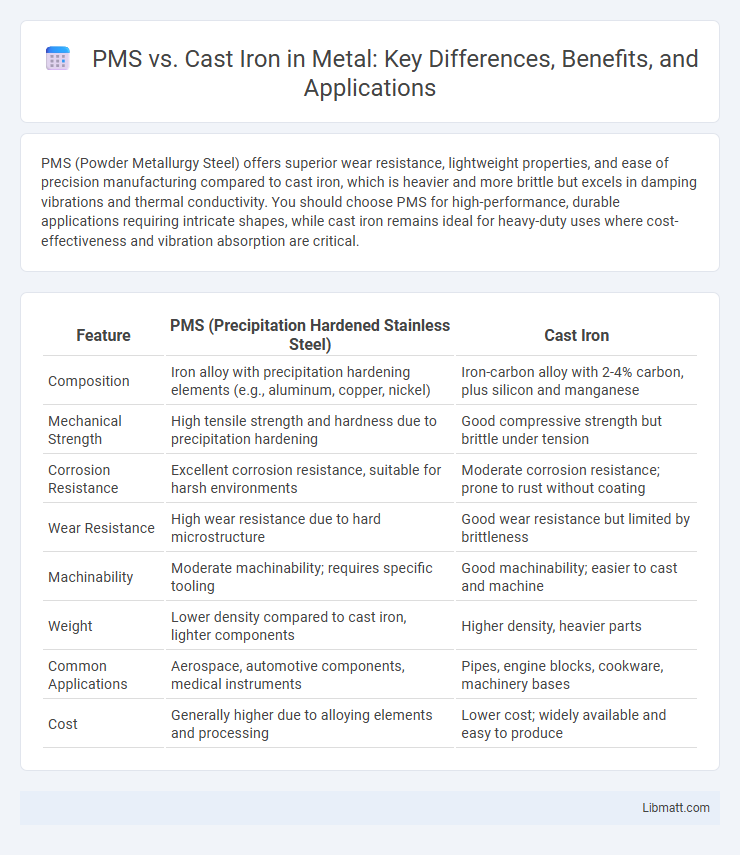

PMS (Powder Metallurgy Steel) offers superior wear resistance, lightweight properties, and ease of precision manufacturing compared to cast iron, which is heavier and more brittle but excels in damping vibrations and thermal conductivity. You should choose PMS for high-performance, durable applications requiring intricate shapes, while cast iron remains ideal for heavy-duty uses where cost-effectiveness and vibration absorption are critical.

Table of Comparison

| Feature | PMS (Precipitation Hardened Stainless Steel) | Cast Iron |

|---|---|---|

| Composition | Iron alloy with precipitation hardening elements (e.g., aluminum, copper, nickel) | Iron-carbon alloy with 2-4% carbon, plus silicon and manganese |

| Mechanical Strength | High tensile strength and hardness due to precipitation hardening | Good compressive strength but brittle under tension |

| Corrosion Resistance | Excellent corrosion resistance, suitable for harsh environments | Moderate corrosion resistance; prone to rust without coating |

| Wear Resistance | High wear resistance due to hard microstructure | Good wear resistance but limited by brittleness |

| Machinability | Moderate machinability; requires specific tooling | Good machinability; easier to cast and machine |

| Weight | Lower density compared to cast iron, lighter components | Higher density, heavier parts |

| Common Applications | Aerospace, automotive components, medical instruments | Pipes, engine blocks, cookware, machinery bases |

| Cost | Generally higher due to alloying elements and processing | Lower cost; widely available and easy to produce |

Introduction to PMS and Cast Iron

Powder Metal Steel (PMS) offers enhanced strength, wear resistance, and manufacturing precision compared to traditional cast iron, making it ideal for complex, high-performance components. Cast iron, known for its excellent machinability, vibration damping, and cost-effectiveness, remains widely used in heavy-duty applications such as engine blocks and machinery bases. The choice between PMS and cast iron depends on the specific mechanical properties and production requirements of the intended application.

Material Composition: PMS vs Cast Iron

PMS (Powdered Metal Steel) is composed of finely powdered steel particles compacted and sintered to create a uniform, dense material, offering high wear resistance and strength. Cast iron, primarily made from iron, carbon (2-4%), and silicon, is known for its excellent castability, compressive strength, and good vibration damping properties. Your choice between PMS and cast iron depends on the desired mechanical properties, machining capabilities, and application-specific requirements.

Mechanical Properties Comparison

PMS (Powder Metallurgy Steel) exhibits higher tensile strength and improved wear resistance compared to traditional cast iron, making it suitable for applications requiring enhanced durability. Cast iron offers superior compressive strength and excellent damping capacity but is more brittle and prone to fracture under impact stress. The microstructure differences, with PMS's uniform particle distribution versus cast iron's graphite flakes, significantly influence their mechanical performance and application suitability.

Durability and Longevity

PMS helmets are engineered with advanced composite materials that offer superior impact resistance and longer-lasting durability compared to traditional cast iron helmets. Cast iron, while strong, is prone to rust and wear over time, which can compromise its protective qualities and lifespan. Choosing PMS ensures your helmet remains reliable and effective for extended use in demanding environments.

Corrosion Resistance: PMS vs Cast Iron

PMS (Plated Metal Steel) offers superior corrosion resistance compared to cast iron due to its protective plated coating that prevents rust and degradation in harsh environments. Cast iron is more prone to corrosion, especially when exposed to moisture and acidic conditions, requiring frequent maintenance or protective treatments. Your choice of PMS ensures longer durability and lower maintenance costs in corrosive settings.

Manufacturing Processes

PMS (Powder Metallurgy Steel) manufacturing involves compacting metal powders into a desired shape and then sintering them at high temperatures, enabling precise control over material properties and minimal waste. Cast iron production requires melting iron with carbon and other elements, pouring the molten metal into molds, and allowing it to solidify, which typically results in a denser but more brittle material. Your choice between PMS and cast iron should consider the specific manufacturing processes that affect durability, dimensional accuracy, and production efficiency.

Weight and Ease of Handling

PMS (Powder Metallurgy Steel) cookware is significantly lighter than traditional cast iron, making it easier for you to handle during cooking and cleaning. Cast iron's dense composition results in a heavier weight, which can be challenging to maneuver, especially when full. The lightweight nature of PMS cookware enhances user comfort without compromising durability.

Applications in Industry

PMS (Powder Metallurgy Steel) offers superior wear resistance and dimensional precision for automotive and aerospace components, optimizing performance in high-stress environments. Cast iron remains the preferred choice for heavy-duty machinery bases and engine blocks due to its excellent vibration damping and thermal conductivity. Industry applications prioritize PMS in parts requiring high strength-to-weight ratios, while cast iron dominates cost-effective, durable structural components.

Cost-Effectiveness Analysis

PMS (Powder Metallurgy Steel) offers greater cost-effectiveness compared to cast iron due to its lower material waste and reduced machining time, which leads to decreased manufacturing expenses. While cast iron typically has a lower raw material cost, PMS enables higher precision and better mechanical properties, reducing the need for frequent replacements and maintenance. Over the product lifecycle, PMS parts provide superior value by combining durability with efficient production processes, resulting in overall cost savings.

Environmental Impact and Sustainability

PMS (Powder Metallurgical Steel) manufacturing typically results in lower carbon emissions and reduced energy consumption compared to cast iron production, due to its near-net shape fabrication minimizing material waste. Cast iron involves high-temperature melting and molding processes, resulting in significant CO2 emissions and resource intensity. PMS offers enhanced recyclability and efficiency in raw material usage, making it a more sustainable choice for environmentally conscious industries.

PMS vs cast iron Infographic

libmatt.com

libmatt.com