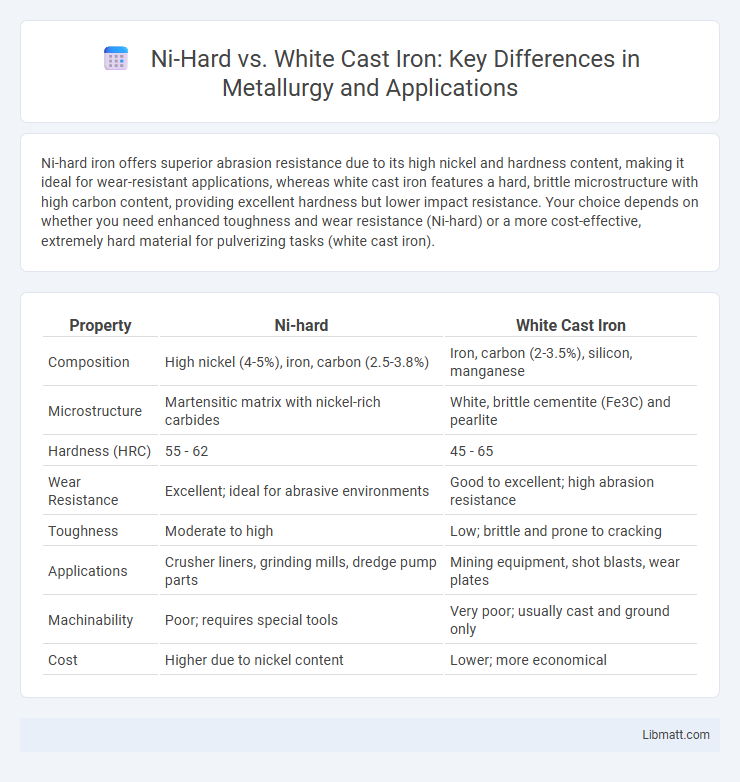

Ni-hard iron offers superior abrasion resistance due to its high nickel and hardness content, making it ideal for wear-resistant applications, whereas white cast iron features a hard, brittle microstructure with high carbon content, providing excellent hardness but lower impact resistance. Your choice depends on whether you need enhanced toughness and wear resistance (Ni-hard) or a more cost-effective, extremely hard material for pulverizing tasks (white cast iron).

Table of Comparison

| Property | Ni-hard | White Cast Iron |

|---|---|---|

| Composition | High nickel (4-5%), iron, carbon (2.5-3.8%) | Iron, carbon (2-3.5%), silicon, manganese |

| Microstructure | Martensitic matrix with nickel-rich carbides | White, brittle cementite (Fe3C) and pearlite |

| Hardness (HRC) | 55 - 62 | 45 - 65 |

| Wear Resistance | Excellent; ideal for abrasive environments | Good to excellent; high abrasion resistance |

| Toughness | Moderate to high | Low; brittle and prone to cracking |

| Applications | Crusher liners, grinding mills, dredge pump parts | Mining equipment, shot blasts, wear plates |

| Machinability | Poor; requires special tools | Very poor; usually cast and ground only |

| Cost | Higher due to nickel content | Lower; more economical |

Introduction to Ni-Hard and White Cast Iron

Ni-Hard and white cast iron are both high-carbon alloys known for their exceptional hardness and wear resistance, commonly used in industrial applications requiring abrasion durability. Ni-Hard contains significant nickel content, enhancing toughness and resistance to chipping, while white cast iron is characterized by its brittle, hard microstructure due to rapid cooling that produces cementite flakes. Understanding the differences in composition and mechanical properties helps you select the right material for demanding environments such as mining, crushing, and grinding equipment.

Chemical Composition Comparison

Ni-hard cast iron contains 1.8-3.5% nickel, 1.8-3.5% chromium, and 2.0-3.0% carbon, enhancing its abrasion resistance and toughness. White cast iron typically has lower nickel and chromium content, with 1.8-3.6% carbon and minimal alloying elements, resulting in a hard, brittle microstructure dominated by cementite. The addition of nickel and chromium in Ni-hard iron refines the microstructure, improving impact resistance compared to the high hardness but brittle nature of white cast iron.

Microstructure Differences

Ni-hard cast iron features a microstructure characterized by martensitic or austenitic matrices with uniformly dispersed hard chromium carbides, enhancing abrasion resistance and toughness. White cast iron exhibits a microstructure dominated by ledeburite, consisting of a mixture of cementite and austenite that transforms into hard, brittle phases upon cooling. These microstructural distinctions influence Ni-hard's superior wear resistance and shock absorption compared to the harder but more brittle white cast iron.

Mechanical Properties of Ni-Hard vs White Cast Iron

Ni-Hard cast iron exhibits superior abrasion resistance and higher tensile strength compared to traditional white cast iron, making it ideal for high-wear applications such as crushers and grinding mills. White cast iron, while harder and more brittle due to its high carbon content in the form of cementite, offers excellent compressive strength but lower impact resistance. Understanding these mechanical property differences ensures you select the appropriate material for durability and performance under specific operational stresses.

Wear Resistance Analysis

Ni-hard cast iron exhibits superior wear resistance compared to white cast iron due to its high nickel content, which enhances toughness and impact strength in abrasive environments. White cast iron, characterized by a high carbon content forming hard cementite, shows excellent hardness but tends to be more brittle and prone to cracking under impact wear conditions. The microstructure of Ni-hard combines martensite and austenite phases, significantly improving its durability in heavy abrasive wear applications compared to the predominantly cementite-rich matrix of white cast iron.

Applications in Industry

Ni-hard cast iron, known for its exceptional abrasion resistance and impact strength, is widely used in the mining, cement, and sugar industries for components such as crusher liners, grinding mill liners, and impellers. White cast iron, characterized by a hard, brittle structure due to its high carbon content in the form of cementite, finds applications in wear-resistant surfaces, such as in shot-blasting nozzles and railway track components where high hardness is critical. Both materials serve essential roles in heavy-duty industrial environments requiring superior hardness and durability to withstand severe wear conditions.

Machinability and Castability

Ni-hard cast iron exhibits superior machinability compared to white cast iron due to its alloyed composition with high nickel content, which enhances toughness and wear resistance while allowing easier cutting and shaping. In contrast, white cast iron has high hardness and brittleness caused by cementite, resulting in poor machinability and increased tool wear during processing. Regarding castability, Ni-hard offers better fluidity and reduced casting defects, making it preferable for complex molds, whereas white cast iron tends to have limited castability due to rapid solidification and shrinkage issues.

Cost and Availability

Ni-hard cast iron generally costs more than white cast iron due to the addition of nickel and its specialized production process, which enhances wear resistance and toughness. White cast iron is widely available and more affordable, making it a popular choice for applications requiring hardness at a lower cost. The higher cost and relative scarcity of Ni-hard cast iron limit its use to industries where superior abrasion resistance justifies the investment.

Advantages and Disadvantages

Ni-hard cast iron offers superior wear resistance and toughness due to its high nickel and chromium content, making it ideal for applications like grinding balls and crusher parts. Its main disadvantage is higher cost and susceptibility to cracking under extreme thermal shock. White cast iron provides excellent hardness and abrasion resistance at a lower cost but is brittle and prone to chipping, limiting its use in impact-heavy environments.

Choosing Between Ni-Hard and White Cast Iron

Choosing between Ni-hard and white cast iron depends on your application's abrasion resistance and toughness requirements. Ni-hard cast iron, alloyed with high nickel content, offers superior wear resistance and toughness, making it ideal for high-impact environments like mining and crushing equipment. White cast iron, characterized by its hard and brittle surface, excels in wear resistance but is less ductile, suitable for applications where toughness is less critical.

Ni-hard vs white cast iron Infographic

libmatt.com

libmatt.com