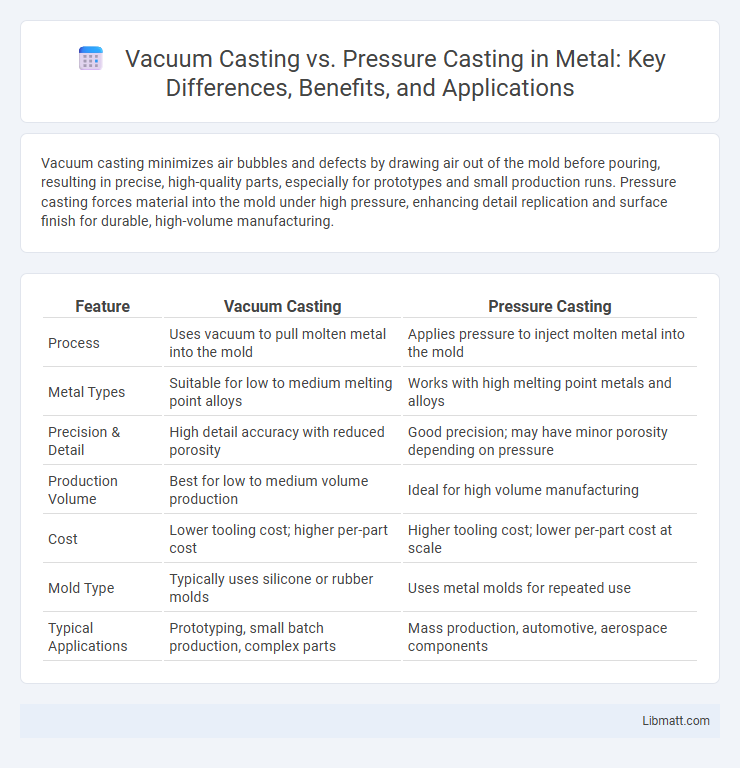

Vacuum casting minimizes air bubbles and defects by drawing air out of the mold before pouring, resulting in precise, high-quality parts, especially for prototypes and small production runs. Pressure casting forces material into the mold under high pressure, enhancing detail replication and surface finish for durable, high-volume manufacturing.

Table of Comparison

| Feature | Vacuum Casting | Pressure Casting |

|---|---|---|

| Process | Uses vacuum to pull molten metal into the mold | Applies pressure to inject molten metal into the mold |

| Metal Types | Suitable for low to medium melting point alloys | Works with high melting point metals and alloys |

| Precision & Detail | High detail accuracy with reduced porosity | Good precision; may have minor porosity depending on pressure |

| Production Volume | Best for low to medium volume production | Ideal for high volume manufacturing |

| Cost | Lower tooling cost; higher per-part cost | Higher tooling cost; lower per-part cost at scale |

| Mold Type | Typically uses silicone or rubber molds | Uses metal molds for repeated use |

| Typical Applications | Prototyping, small batch production, complex parts | Mass production, automotive, aerospace components |

Introduction to Vacuum Casting and Pressure Casting

Vacuum casting uses a vacuum environment to draw liquid material into a mold, ensuring reduced air bubbles and high detail accuracy, making it ideal for small production runs and prototypes. Pressure casting applies external pressure to force the molten material into the mold, resulting in denser and more durable parts suitable for high-volume manufacturing. Both methods optimize material flow and surface finish but differ in application scope, cost, and production scale.

What is Vacuum Casting?

Vacuum casting is a manufacturing process that involves pouring liquid material into a mold under vacuum conditions to eliminate air bubbles and improve surface quality. This technique ensures high precision and fine detail replication, making it ideal for prototyping and small batch production of complex parts. Your products benefit from reduced defects and enhanced structural integrity due to the controlled environment during vacuum casting.

What is Pressure Casting?

Pressure casting is a manufacturing process that injects molten metal into a mold under high pressure, ensuring precise filling and minimizing porosity. This method produces dense, high-quality parts with excellent surface finish and dimensional accuracy, making it ideal for complex and thin-walled components. Compared to vacuum casting, pressure casting offers faster cycle times and better mechanical properties due to controlled metal solidification.

Key Differences Between Vacuum and Pressure Casting

Vacuum casting uses a vacuum to draw resin into molds, minimizing air bubbles and ensuring high-detail replication ideal for prototyping and small batch production. Pressure casting applies high pressure during curing to reduce voids and improve mechanical properties, resulting in stronger and denser parts suited for functional testing and larger production runs. The primary difference lies in vacuum casting's focus on precision and surface finish, while pressure casting emphasizes strength and durability.

Material Suitability: Vacuum vs Pressure Casting

Vacuum casting excels with silicone, polyurethane, and certain thermoplastics, providing high detail and minimal air entrapment ideal for prototypes and small production runs. Pressure casting is better suited for resins and metals requiring higher density and mechanical strength, ensuring reduced porosity and improved structural integrity. Your material choice heavily influences whether vacuum or pressure casting delivers optimal performance and finish.

Advantages of Vacuum Casting

Vacuum casting offers superior precision and reduced air bubble formation by removing trapped gases, resulting in higher quality and more detailed parts compared to pressure casting. It allows for better replication of complex geometries and smooth surface finishes, making it ideal for prototypes and small batch production. Your project benefits from shorter cycle times and lower material wastage due to improved mold filling and minimal porosity.

Advantages of Pressure Casting

Pressure casting offers superior dimensional accuracy and surface finish compared to vacuum casting, making it ideal for producing complex and detailed parts. The process ensures faster mold filling and reduces the likelihood of air entrapment, leading to fewer defects and improved mechanical properties. Pressure casting also supports higher production rates and better material utilization, enhancing overall manufacturing efficiency.

Typical Applications for Each Method

Vacuum casting is typically used for producing high-precision prototypes, low-volume production parts, and intricate components in industries such as automotive, aerospace, and medical devices due to its ability to minimize air bubbles and improve surface finish. Pressure casting is commonly employed in mass production settings for metal parts like aluminum alloys in automotive engine blocks, housings, and structural components, where higher productivity and strength are essential. Both methods serve distinct purposes: vacuum casting excels in detail and surface quality for prototyping, while pressure casting is ideal for durable, high-volume metal parts in industrial applications.

Cost Comparison: Vacuum Casting vs Pressure Casting

Vacuum casting typically involves lower initial tooling costs and is more cost-effective for small to medium production runs due to reduced material waste and shorter mold preparation times. Pressure casting requires higher upfront investment in durable molds and equipment, but offers lower per-unit costs for large volume production because of faster cycle times and improved material density. Evaluating production scale and budget constraints is critical in determining the most cost-efficient casting method between vacuum and pressure casting.

Choosing the Right Casting Process for Your Project

Vacuum casting offers precise control over material flow and minimizes air bubbles, making it ideal for prototyping and low-volume production with complex geometries. Pressure casting provides faster cycle times and higher density parts, suitable for large-scale manufacturing and metals with high melting points. Understanding your project's requirements for detail, production volume, and material properties will help you choose the most efficient casting process.

Vacuum casting vs pressure casting Infographic

libmatt.com

libmatt.com