Forged steel offers superior strength and durability due to its grain structure being compressed and aligned during the forging process, making it ideal for high-stress applications. Cast steel, while more versatile and cost-effective for complex shapes, typically has a coarser grain structure, which can result in lower toughness and impact resistance compared to forged steel.

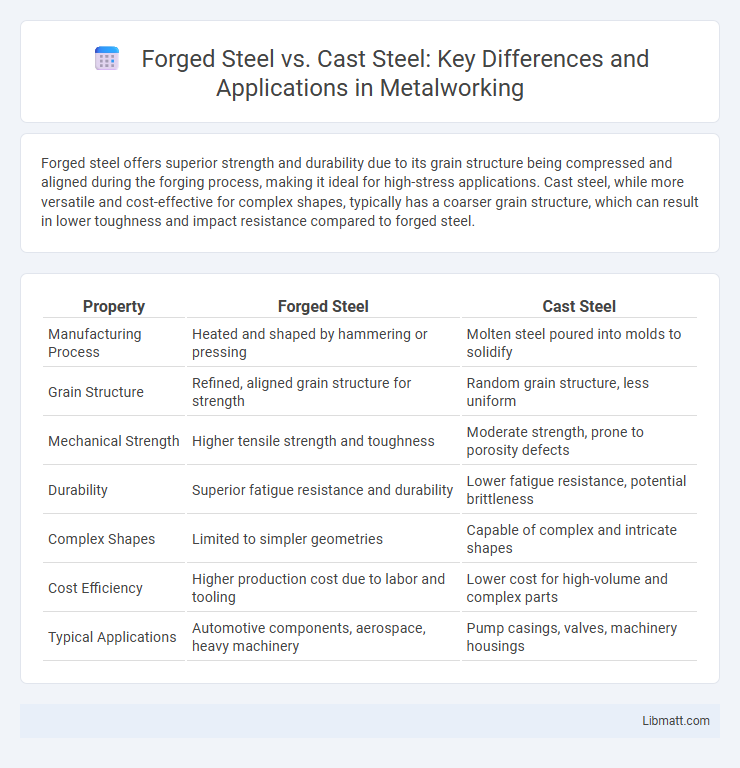

Table of Comparison

| Property | Forged Steel | Cast Steel |

|---|---|---|

| Manufacturing Process | Heated and shaped by hammering or pressing | Molten steel poured into molds to solidify |

| Grain Structure | Refined, aligned grain structure for strength | Random grain structure, less uniform |

| Mechanical Strength | Higher tensile strength and toughness | Moderate strength, prone to porosity defects |

| Durability | Superior fatigue resistance and durability | Lower fatigue resistance, potential brittleness |

| Complex Shapes | Limited to simpler geometries | Capable of complex and intricate shapes |

| Cost Efficiency | Higher production cost due to labor and tooling | Lower cost for high-volume and complex parts |

| Typical Applications | Automotive components, aerospace, heavy machinery | Pump casings, valves, machinery housings |

Introduction to Forged Steel and Cast Steel

Forged steel is produced by shaping heated steel through compressive forces, resulting in a dense, grain-refined structure that enhances strength and toughness. Cast steel is formed by pouring molten steel into molds, allowing for complex shapes but generally exhibiting lower mechanical properties due to potential porosity and grain size variability. The distinct manufacturing processes of forged and cast steel significantly impact their microstructure, mechanical performance, and suitability for high-stress applications.

Manufacturing Processes Explained

Forged steel is produced by shaping heated metal using compressive forces, enhancing its grain structure and resulting in superior strength and toughness compared to cast steel. Cast steel is made by pouring molten metal into molds, allowing for complex shapes but with potential internal porosity and less uniform grain structure. Understanding these manufacturing processes helps you choose the right steel type based on strength requirements and application needs.

Key Differences in Material Properties

Forged steel exhibits superior strength, toughness, and fatigue resistance compared to cast steel due to its refined grain structure and reduced porosity from the forging process. Cast steel, while more cost-effective and capable of producing complex shapes, often contains internal voids and has lower impact resistance and ductility. Understanding these key differences helps you choose the right material for applications requiring enhanced mechanical performance and reliability.

Strength and Durability Comparison

Forged steel exhibits superior strength and durability compared to cast steel due to its refined grain structure and reduced porosity, resulting from the forging process that aligns the metal's fibers. Cast steel, while versatile and cost-effective for complex shapes, tends to have higher susceptibility to internal defects such as voids and inclusions, which can compromise its mechanical properties under stress. Your choice between forged and cast steel should consider the application's demand for toughness and resistance to impact, where forged steel typically offers enhanced performance.

Cost Factors: Forged Steel vs Cast Steel

Forged steel generally incurs higher production costs due to its labor-intensive manufacturing process and the need for expensive tooling and machinery, whereas cast steel offers a more cost-effective option thanks to its ability to create complex shapes with less machining. The material properties of forged steel, such as enhanced strength and toughness from grain alignment, justify the premium price in high-stress applications. When evaluating your project budget, consider that cast steel's lower initial cost may be offset by reduced mechanical performance compared to forged steel.

Common Industrial Applications

Forged steel is widely used in high-stress applications such as aerospace, automotive drivetrain components, and heavy machinery due to its superior strength and fatigue resistance. Cast steel finds common industrial applications in complex-shaped parts like valves, pump housings, and large structural components where intricate designs and cost-effectiveness are essential. Both materials serve critical roles in manufacturing pipelines, pressure vessels, and construction equipment, with selection driven by mechanical properties and production methods.

Performance Under Stress and Impact

Forged steel exhibits superior performance under stress and impact due to its refined grain structure and aligned internal fibers, which enhance toughness and resistance to fatigue. Cast steel, while versatile and cost-effective, tends to have a coarser grain structure with potential internal voids that can reduce its ability to withstand high-impact forces. Industries requiring high reliability under dynamic loads, such as aerospace and automotive, often prefer forged steel for critical components because of its enhanced strength and durability.

Corrosion Resistance and Longevity

Forged steel exhibits superior corrosion resistance compared to cast steel due to its denser grain structure and fewer internal defects, which minimize areas susceptible to rust and oxidation. The enhanced mechanical properties of forged steel contribute to greater longevity, especially in harsh environments, as the material withstands stress and wear more effectively. Cast steel, while versatile and cost-effective, typically has a more porous microstructure that can lead to increased corrosion rates and shorter service life in corrosive settings.

Selecting the Right Material for Your Project

Choosing between forged steel and cast steel depends on the specific performance requirements of your project, such as strength, toughness, and dimensional accuracy. Forged steel offers superior strength and fatigue resistance due to its grain flow alignment, making it ideal for critical components subjected to high stress or impact. Cast steel allows for more complex shapes and large sizes with excellent machinability but generally has lower mechanical properties, suitable for less demanding applications or intricate geometries.

Conclusion: Which Is Better?

Forged steel offers superior strength, toughness, and fatigue resistance due to its refined grain structure formed under compressive forces, making it ideal for high-stress applications. Cast steel provides cost-effective manufacturing and complex shapes but typically has lower mechanical properties and increased porosity risks. For critical components requiring maximum durability and impact resistance, forged steel is generally the better choice.

forged steel vs cast steel Infographic

libmatt.com

libmatt.com