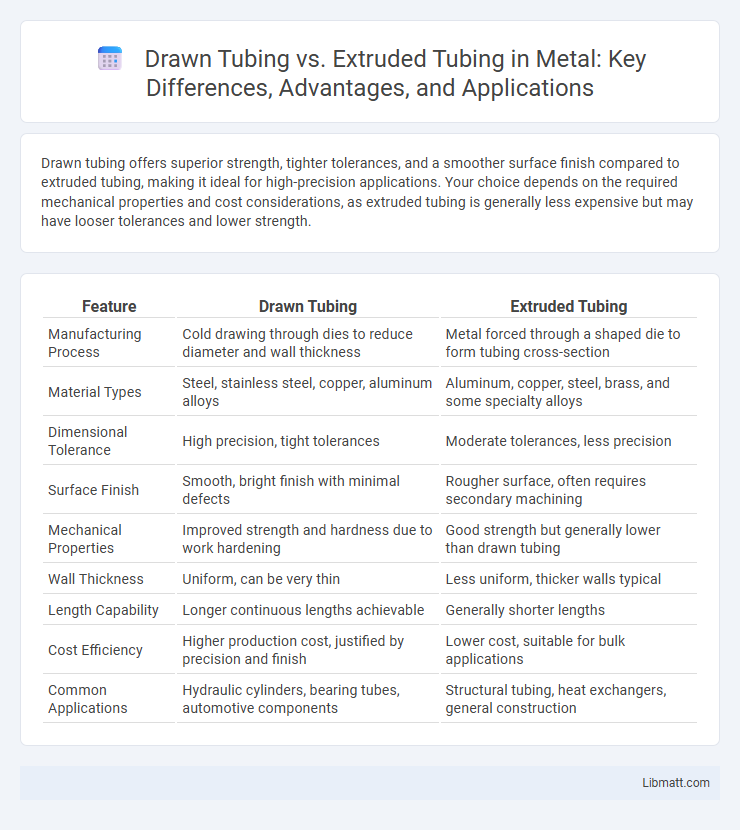

Drawn tubing offers superior strength, tighter tolerances, and a smoother surface finish compared to extruded tubing, making it ideal for high-precision applications. Your choice depends on the required mechanical properties and cost considerations, as extruded tubing is generally less expensive but may have looser tolerances and lower strength.

Table of Comparison

| Feature | Drawn Tubing | Extruded Tubing |

|---|---|---|

| Manufacturing Process | Cold drawing through dies to reduce diameter and wall thickness | Metal forced through a shaped die to form tubing cross-section |

| Material Types | Steel, stainless steel, copper, aluminum alloys | Aluminum, copper, steel, brass, and some specialty alloys |

| Dimensional Tolerance | High precision, tight tolerances | Moderate tolerances, less precision |

| Surface Finish | Smooth, bright finish with minimal defects | Rougher surface, often requires secondary machining |

| Mechanical Properties | Improved strength and hardness due to work hardening | Good strength but generally lower than drawn tubing |

| Wall Thickness | Uniform, can be very thin | Less uniform, thicker walls typical |

| Length Capability | Longer continuous lengths achievable | Generally shorter lengths |

| Cost Efficiency | Higher production cost, justified by precision and finish | Lower cost, suitable for bulk applications |

| Common Applications | Hydraulic cylinders, bearing tubes, automotive components | Structural tubing, heat exchangers, general construction |

Introduction to Drawn vs. Extruded Tubing

Drawn tubing is manufactured by pulling a hollow tube through a die to achieve precise dimensions, smooth surfaces, and improved mechanical properties, making it ideal for applications requiring tight tolerances. Extruded tubing involves pushing heated metal through a die to form a tube, which typically results in thicker walls and less dimensional accuracy compared to drawn tubing. Understanding the differences between drawn and extruded tubing helps you select the best method for strength, surface finish, and precision in your projects.

Manufacturing Processes Explained

Drawn tubing involves pulling a tube through a die to reduce diameter and enhance surface finish and mechanical properties, resulting in precise dimensions and improved strength. Extruded tubing is produced by forcing heated metal through a shaped die, allowing complex cross-sections but with less dimensional accuracy compared to drawn tubing. Your choice depends on whether you prioritize the superior surface quality and strength of drawn tubing or the design flexibility and cost-effectiveness of extrusion.

Key Material Differences

Drawn tubing and extruded tubing differ significantly in their microstructure and mechanical properties due to their manufacturing processes. Drawn tubing undergoes cold working, which enhances its strength, surface finish, and dimensional accuracy by refining the grain structure, while extruded tubing is shaped by forcing material through a die, resulting in coarser grain structures and potentially lower tensile strength. Your choice between these tubing types should consider the required strength, surface quality, and dimensional tolerances for your application.

Dimensional Accuracy and Tolerances

Drawn tubing exhibits superior dimensional accuracy and tighter tolerances compared to extruded tubing due to the cold working process that enhances uniformity and precision. Extruded tubing typically has looser tolerances because the hot forming process can introduce variations in wall thickness and diameter. For applications requiring exact measurements and consistency, drawn tubing is the preferred choice to ensure reliability and optimal performance.

Mechanical Properties Comparison

Drawn tubing exhibits superior mechanical properties compared to extruded tubing due to its manufacturing process that involves cold working, which increases tensile strength, hardness, and surface finish quality. Extruded tubing typically has lower yield strength and ductility because it is produced by forcing material through a die at high temperature, causing a more uniform but less dense microstructure. The enhanced mechanical performance of drawn tubing makes it preferable in applications requiring high precision, improved fatigue resistance, and better dimensional tolerances.

Surface Finish and Cleanliness

Drawn tubing offers superior surface finish with a smoother, more polished exterior due to the cold working process, which also reduces surface defects and enhances cleanliness by minimizing contaminants. Extruded tubing typically has a rougher surface finish and may require additional cleaning or machining to achieve comparable cleanliness levels. The cold drawing process improves dimensional accuracy and surface integrity, making drawn tubing ideal for applications demanding high purity and aesthetic quality.

Application Suitability

Drawn tubing offers superior dimensional accuracy and surface finish, making it ideal for applications requiring precise tolerances such as automotive fuel lines and hydraulic systems. Extruded tubing, with its cost-effective production and ability to form complex cross-sections, suits applications like HVAC ducts and structural components where tight tolerances are less critical. Choosing the right tubing depends on your need for precision, surface quality, and budget constraints tied to your specific application.

Cost Considerations

Drawn tubing generally incurs higher costs due to its precise manufacturing process that produces tighter tolerances and superior surface finish, making it ideal for applications demanding high quality. Extruded tubing offers a more cost-effective solution by using a simpler production technique suited for larger volumes and less stringent specifications. Your choice between drawn and extruded tubing should balance budget constraints with the performance requirements of your project.

Common Industries and Use Cases

Drawn tubing is widely used in the automotive and aerospace industries due to its enhanced strength and precise dimensional tolerances, ideal for fuel lines, hydraulic systems, and structural components. Extruded tubing finds common applications in construction, HVAC, and consumer goods sectors, offering versatile shapes and sizes suitable for ductwork, electrical conduit, and fluid transport. Both tubing types serve medical device manufacturing for surgical instruments and implants, where material consistency and biocompatibility are critical.

Choosing the Right Tubing Method

Selecting the appropriate tubing method depends on key factors such as dimensional accuracy, surface finish, and material properties. Drawn tubing offers superior strength and tighter tolerances due to cold working processes, making it ideal for high-precision applications requiring durability. Your choice between drawn and extruded tubing should align with the specific requirements of your project, balancing cost-effectiveness with mechanical performance.

drawn tubing vs extruded tubing Infographic

libmatt.com

libmatt.com