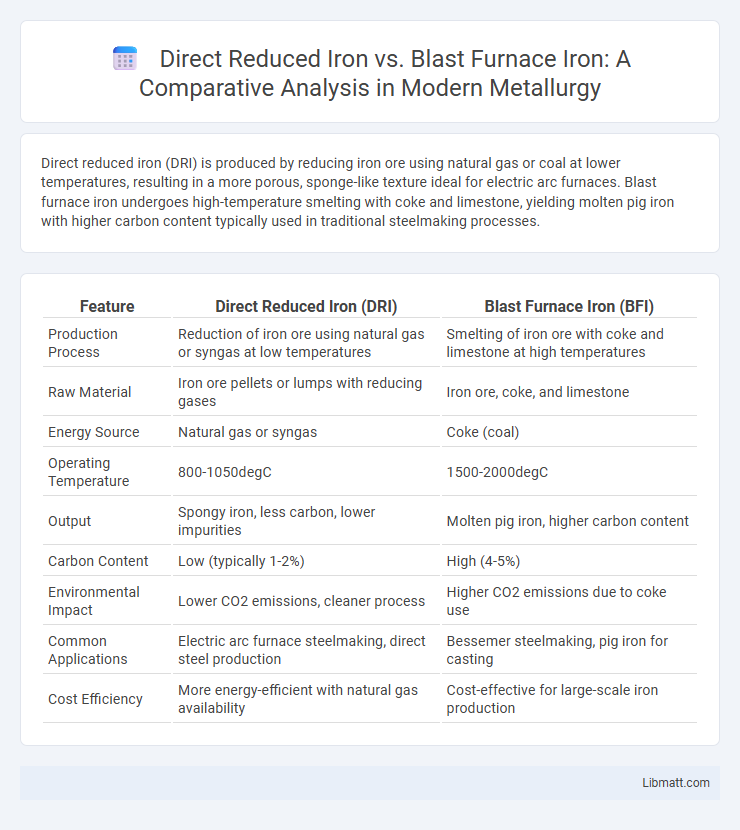

Direct reduced iron (DRI) is produced by reducing iron ore using natural gas or coal at lower temperatures, resulting in a more porous, sponge-like texture ideal for electric arc furnaces. Blast furnace iron undergoes high-temperature smelting with coke and limestone, yielding molten pig iron with higher carbon content typically used in traditional steelmaking processes.

Table of Comparison

| Feature | Direct Reduced Iron (DRI) | Blast Furnace Iron (BFI) |

|---|---|---|

| Production Process | Reduction of iron ore using natural gas or syngas at low temperatures | Smelting of iron ore with coke and limestone at high temperatures |

| Raw Material | Iron ore pellets or lumps with reducing gases | Iron ore, coke, and limestone |

| Energy Source | Natural gas or syngas | Coke (coal) |

| Operating Temperature | 800-1050degC | 1500-2000degC |

| Output | Spongy iron, less carbon, lower impurities | Molten pig iron, higher carbon content |

| Carbon Content | Low (typically 1-2%) | High (4-5%) |

| Environmental Impact | Lower CO2 emissions, cleaner process | Higher CO2 emissions due to coke use |

| Common Applications | Electric arc furnace steelmaking, direct steel production | Bessemer steelmaking, pig iron for casting |

| Cost Efficiency | More energy-efficient with natural gas availability | Cost-effective for large-scale iron production |

Overview of Direct Reduced Iron (DRI) and Blast Furnace Iron

Direct Reduced Iron (DRI) is produced by reducing iron ore using natural gas or coal at temperatures below the melting point, preserving its metallic form without melting. Blast Furnace Iron involves smelting iron ore with coke and limestone at high temperatures, resulting in molten pig iron that requires further refining. DRI offers lower energy consumption and fewer emissions, while blast furnace iron remains dominant for large-scale steelmaking due to its high production capacity.

Key Differences in Production Processes

Direct reduced iron (DRI) is produced by reducing iron ore using natural gas or syngas at temperatures below the melting point, preserving the metallic iron in solid form. Blast furnace iron involves smelting iron ore with coke and limestone at high temperatures, creating molten pig iron requiring further refining. Your choice between these methods affects energy consumption, emissions, and the quality of the final iron product.

Raw Materials Used in DRI vs Blast Furnace

Direct Reduced Iron (DRI) primarily uses iron ore pellets and natural gas or coal as a reducing agent, minimizing reliance on coke and flux materials. In contrast, blast furnace iron production relies heavily on iron ore, coke made from coal, and limestone as flux to remove impurities. Your choice between DRI and blast furnace iron can affect raw material sourcing, energy consumption, and environmental impact due to these distinct inputs.

Energy Consumption Comparison

Direct reduced iron (DRI) production consumes significantly less energy compared to blast furnace ironmaking, as it primarily uses natural gas or syngas instead of coke. The energy intensity of DRI processes typically ranges from 12 to 20 GJ per ton of iron, whereas blast furnaces require approximately 18 to 25 GJ per ton due to coke production and higher operational temperatures. Lower carbon emissions and reduced reliance on coal contribute to DRI's improved energy efficiency and environmental performance in steel production.

Environmental Impact and Emissions

Direct reduced iron (DRI) significantly reduces greenhouse gas emissions compared to blast furnace iron by utilizing natural gas or hydrogen instead of coke, resulting in lower carbon dioxide output. Blast furnace iron production relies heavily on coal, generating substantial CO2, sulfur oxides, and particulates that contribute to air pollution and climate change. Your choice of DRI can substantially decrease environmental impact while supporting cleaner steel manufacturing processes.

Product Quality and Chemical Composition

Direct Reduced Iron (DRI) offers higher purity with lower sulfur and phosphorus content compared to Blast Furnace Iron, resulting in improved steel quality. Blast Furnace Iron typically contains higher levels of carbon and impurities due to coke use, which can affect the chemical composition and mechanical properties. You benefit from DRI's consistent composition when producing high-grade steel requiring precise control over alloying elements.

Cost Analysis: DRI vs Blast Furnace Iron

Direct Reduced Iron (DRI) typically incurs lower operational costs compared to Blast Furnace Iron due to reduced energy consumption and the use of natural gas instead of coke, which is more expensive. Capital expenditure for Blast Furnaces is significantly higher because of the complex infrastructure and large scale required, whereas DRI plants have smaller footprints and simpler setups. Overall, DRI offers cost advantages in regions with abundant natural gas and moderate steel demand, while Blast Furnace Iron remains cost-effective in areas with cheaper coke and large-scale production capabilities.

Applications in the Steel Industry

Direct reduced iron (DRI) is primarily used in electric arc furnaces (EAF) for producing high-quality steel with lower carbon emissions, making it ideal for mini-mills and specialty steel producers. Blast furnace iron, or pig iron, serves as a key raw material in traditional integrated steel plants, where it is further refined in basic oxygen furnaces (BOF) to manufacture large volumes of steel. The choice between DRI and blast furnace iron depends on factors such as energy costs, raw material availability, and environmental regulations, influencing the steel industry's operational and environmental strategies.

Technological Advancements and Innovations

Direct reduced iron (DRI) technology has advanced with innovations such as hydrogen-based reduction and modular reactor designs, significantly reducing carbon emissions compared to traditional blast furnace methods. Blast furnace iron production continues to evolve with enhanced top-gas recycling and pulverized coal injection, improving energy efficiency and output quality. Choosing DRI technology can position your steelmaking process at the forefront of sustainable and efficient production innovations.

Future Trends and Market Outlook

Direct reduced iron (DRI) is gaining momentum due to its lower carbon emissions and compatibility with electric arc furnaces, positioning it as a key material in decarbonizing the steel industry. The market outlook anticipates increased investment in DRI production technologies, driven by stricter environmental regulations and growing demand for green steel in sectors like automotive and construction. Your choice between DRI and blast furnace iron will increasingly depend on sustainability goals and the regulatory landscape shaping steel manufacturing.

direct reduced iron vs blast furnace iron Infographic

libmatt.com

libmatt.com