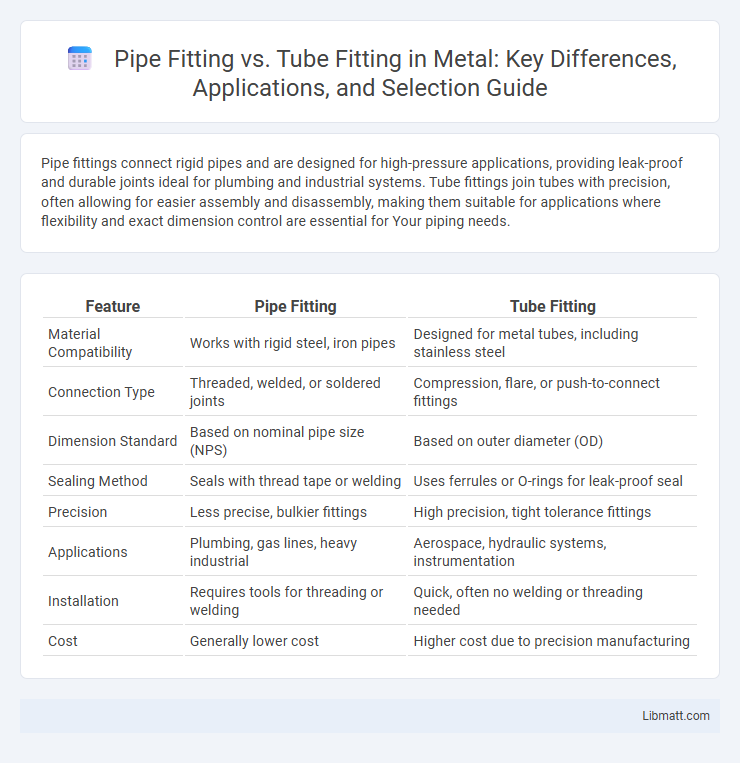

Pipe fittings connect rigid pipes and are designed for high-pressure applications, providing leak-proof and durable joints ideal for plumbing and industrial systems. Tube fittings join tubes with precision, often allowing for easier assembly and disassembly, making them suitable for applications where flexibility and exact dimension control are essential for Your piping needs.

Table of Comparison

| Feature | Pipe Fitting | Tube Fitting |

|---|---|---|

| Material Compatibility | Works with rigid steel, iron pipes | Designed for metal tubes, including stainless steel |

| Connection Type | Threaded, welded, or soldered joints | Compression, flare, or push-to-connect fittings |

| Dimension Standard | Based on nominal pipe size (NPS) | Based on outer diameter (OD) |

| Sealing Method | Seals with thread tape or welding | Uses ferrules or O-rings for leak-proof seal |

| Precision | Less precise, bulkier fittings | High precision, tight tolerance fittings |

| Applications | Plumbing, gas lines, heavy industrial | Aerospace, hydraulic systems, instrumentation |

| Installation | Requires tools for threading or welding | Quick, often no welding or threading needed |

| Cost | Generally lower cost | Higher cost due to precision manufacturing |

Introduction to Pipe Fitting vs Tube Fitting

Pipe fitting and tube fitting are essential components in fluid transport systems, designed to connect, control, and redirect pipes and tubes. Pipe fittings typically accommodate standard-sized pipes with threaded, welded, or grooved ends, while tube fittings use compression or flare connections for precise, leak-free seals in smaller diameter tubing. Understanding the differences in design, application, and material compatibility ensures optimal performance and longevity in plumbing, hydraulic, and industrial systems.

Defining Pipe Fittings

Pipe fittings are components used to connect sections of pipe in plumbing and piping systems, designed to manage the flow of liquids, gases, or solids through pressure-tight joints. They come in various shapes such as elbows, tees, couplings, and reducers, made from materials like steel, copper, and PVC to ensure strength and durability under high-pressure conditions. Unlike tube fittings, pipe fittings typically have thicker walls and are standardized by nominal pipe size (NPS) for consistent compatibility in industrial and residential applications.

Understanding Tube Fittings

Tube fittings are designed to connect, secure, or terminate tubes used in fluid systems, guaranteeing a tight seal and reliable flow control under various pressures. Unlike pipe fittings, which accommodate thicker, threaded pipes, tube fittings often use ferrules or compression mechanisms for leak-free connections, providing precise alignment and ease of assembly. Understanding tube fittings helps you select the right components for your tubing system, ensuring optimal performance and durability in applications such as hydraulic, pneumatic, and gas lines.

Key Differences: Pipe Fittings and Tube Fittings

Pipe fittings are designed for connecting pipes with standardized dimensions and thicker walls, typically used in plumbing and industrial systems to handle high pressure and flow rates. Tube fittings, on the other hand, accommodate tubes with precise outer diameters and thinner walls, offering leak-proof connections ideal for fluid and gas transmission in instrumentation and hydraulic applications. The key differences lie in dimensional standards, application environments, and sealing mechanisms, with pipe fittings relying on threaded or welded joints and tube fittings using compression or flare fittings for secure assembly.

Materials Used in Pipe and Tube Fittings

Pipe fittings are typically made from durable materials such as stainless steel, carbon steel, brass, and PVC, which provide strength and resistance to corrosion in high-pressure applications. Tube fittings, on the other hand, often use materials like stainless steel, brass, and copper to ensure precise connections and prevent leaks in fluid and gas systems. The choice of material is crucial in both pipe and tube fittings to match the requirements of pressure, temperature, and chemical compatibility in industrial and plumbing installations.

Common Applications for Pipe Fittings

Pipe fittings are widely used in plumbing, gas, and water supply systems, offering secure connections for pipes in both residential and industrial environments. These fittings accommodate high-pressure applications and are essential in HVAC, oil, and chemical processing industries where durability and leak prevention are critical. Your choice of pipe fittings ensures reliable joints in complex piping networks, maintaining system integrity in everyday and specialized operations.

Typical Uses of Tube Fittings

Tube fittings are commonly used in applications requiring secure and leak-free connections in hydraulic, pneumatic, and fluid transfer systems. They are typically found in industries such as automotive, aerospace, and chemical processing where precise tube alignment and resistance to vibration are critical. Tube fittings provide reliable performance in high-pressure environments, ensuring effective sealing and maintaining system integrity.

Installation Methods Compared

Pipe fittings and tube fittings differ primarily in their installation methods; pipe fittings typically use threaded, welded, or flanged connections requiring precise alignment and tools for secure joints. Tube fittings often utilize compression or push-to-connect mechanisms, allowing for quicker assembly and disassembly without specialized equipment. This results in tube fittings being preferred for systems needing frequent maintenance, while pipe fittings are favored in high-pressure, permanent installations.

Cost and Maintenance Considerations

Pipe fittings typically cost less than tube fittings due to simpler manufacturing processes and standardized sizes, making them more economical for large-scale plumbing projects. Maintenance of pipe fittings is generally easier and less frequent since their threaded or welded joints offer robust sealing, reducing the risk of leaks over time. Tube fittings, although more expensive upfront, provide precise connections with minimal maintenance needs in high-pressure or specialized applications, balancing cost with long-term reliability.

Choosing the Right Fitting for Your Project

Choosing the right fitting for your project depends on the specific application requirements and material compatibility; pipe fittings are designed for rigid connections in plumbing and industrial systems, while tube fittings provide precise, leak-resistant seals for hydraulic and pneumatic applications. Understanding the differences in thread standards, pressure ratings, and tolerances ensures secure and efficient assembly, minimizing maintenance issues and system failures. Selecting fittings based on tubing or piping dimensions and system pressure demands enhances durability and performance in your engineering or construction project.

Pipe Fitting vs Tube Fitting Infographic

libmatt.com

libmatt.com