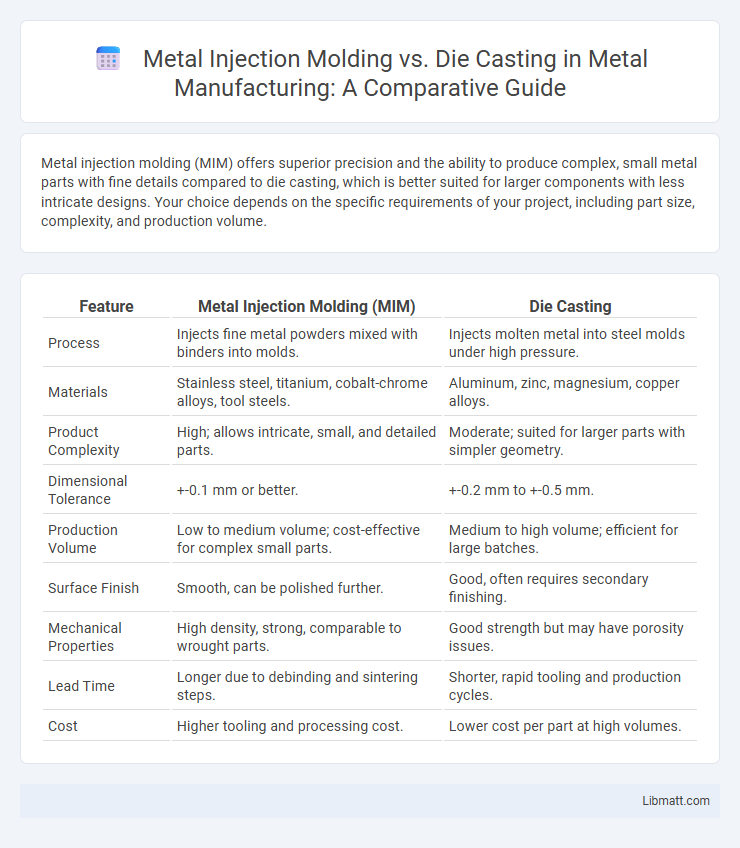

Metal injection molding (MIM) offers superior precision and the ability to produce complex, small metal parts with fine details compared to die casting, which is better suited for larger components with less intricate designs. Your choice depends on the specific requirements of your project, including part size, complexity, and production volume.

Table of Comparison

| Feature | Metal Injection Molding (MIM) | Die Casting |

|---|---|---|

| Process | Injects fine metal powders mixed with binders into molds. | Injects molten metal into steel molds under high pressure. |

| Materials | Stainless steel, titanium, cobalt-chrome alloys, tool steels. | Aluminum, zinc, magnesium, copper alloys. |

| Product Complexity | High; allows intricate, small, and detailed parts. | Moderate; suited for larger parts with simpler geometry. |

| Dimensional Tolerance | +-0.1 mm or better. | +-0.2 mm to +-0.5 mm. |

| Production Volume | Low to medium volume; cost-effective for complex small parts. | Medium to high volume; efficient for large batches. |

| Surface Finish | Smooth, can be polished further. | Good, often requires secondary finishing. |

| Mechanical Properties | High density, strong, comparable to wrought parts. | Good strength but may have porosity issues. |

| Lead Time | Longer due to debinding and sintering steps. | Shorter, rapid tooling and production cycles. |

| Cost | Higher tooling and processing cost. | Lower cost per part at high volumes. |

Introduction to Metal Injection Molding and Die Casting

Metal Injection Molding (MIM) and Die Casting are two precise manufacturing processes for producing complex metal parts with high dimensional accuracy and fine surface finishes. MIM combines powdered metallurgy and injection molding techniques to create small, intricate components from stainless steel, titanium, and other alloys, typically used in medical, automotive, and aerospace industries. Die Casting involves forcing molten metal, such as aluminum, zinc, or magnesium, under high pressure into steel molds, offering rapid production of large, structurally strong parts used extensively in automotive, electronics, and consumer goods sectors.

Process Overview: Metal Injection Molding

Metal Injection Molding (MIM) combines powdered metal and a binder to create a feedstock, which is injected into a mold cavity under high pressure to form intricate and precise components. After molding, parts undergo debinding and sintering processes to achieve high-density metal properties with excellent mechanical strength and complex geometries. Your choice of MIM enables manufacturing of small, detailed metal parts that are difficult to produce with traditional die casting methods.

Process Overview: Die Casting

Die casting involves forcing molten metal into a precision-machined steel mold under high pressure, which rapidly solidifies the metal to form complex shapes with excellent surface finish and dimensional accuracy. This process is ideal for high-volume production of components made from non-ferrous metals like aluminum, zinc, and magnesium, offering enhanced mechanical properties and minimal post-processing. Your choice of die casting ensures consistent quality and tight tolerances for parts used in automotive, aerospace, and consumer electronics industries.

Material Compatibility Comparison

Metal injection molding (MIM) offers superior material compatibility with high-strength alloys such as stainless steel, titanium, and tool steels, enabling intricate designs with excellent mechanical properties. Die casting primarily utilizes non-ferrous metals like aluminum, zinc, and magnesium, which are well-suited for high-volume production but have limitations with ferrous materials. The choice between MIM and die casting depends on the required material properties, component complexity, and production volume.

Design Flexibility and Complexity

Metal injection molding (MIM) offers superior design flexibility and complexity compared to die casting, allowing for intricate geometries and fine features with tight tolerances. MIM enables the production of small, detailed parts with complex internal structures that are difficult or impossible to achieve through die casting. Your choice may depend on the required precision and the complexity of the component design, with MIM providing enhanced options for detailed and high-performance parts.

Production Speed and Efficiency

Metal injection molding (MIM) offers higher production speed and efficiency for small, complex parts due to its ability to produce near-net-shape components with minimal post-processing. Die casting excels in high-volume production of larger parts with rapid cycle times but may require additional machining for precision features. Choosing between MIM and die casting depends on part complexity, volume, and the desired balance between speed and finishing requirements.

Cost Considerations: Tooling and Manufacturing

Metal injection molding typically incurs higher initial tooling costs due to the complexity of molds required for fine, intricate parts, while die casting benefits from more affordable tooling suited for high-volume production. Manufacturing expenses for metal injection molding may be higher per unit at lower volumes, but it excels in producing small, complex components with minimal post-processing. You should consider die casting when aiming for cost-efficiency in large-scale runs and metal injection molding for detailed parts that justify the initial investment.

Mechanical Properties and Surface Finish

Metal injection molding (MIM) offers superior mechanical properties such as higher tensile strength and better wear resistance due to its fine microstructure and uniform material distribution. Die casting provides an excellent surface finish with smooth, precise details, minimizing post-processing efforts in many applications. Your choice depends on whether mechanical performance or surface quality is the priority for the final component.

Common Applications of Each Process

Metal injection molding (MIM) is widely used for producing complex, high-precision components such as medical devices, aerospace parts, and small automotive components due to its ability to manufacture intricate shapes with excellent surface finish. Die casting is favored in the automotive, consumer electronics, and appliance industries for producing large volumes of metal parts like engine blocks, housings, and structural components with high strength and durability. Both processes support mass production but cater to different design complexities and material types, influencing their application in various industrial sectors.

Choosing the Right Process for Your Project

Metal injection molding (MIM) offers high precision and complex geometries suitable for small, intricate parts, making it ideal for applications requiring tight tolerances and material versatility like stainless steel or titanium. Die casting excels in producing larger volumes of parts with excellent surface finish and dimensional accuracy, particularly for non-ferrous metals such as aluminum and zinc alloys, offering cost-effective mass production. Your choice depends on factors like part complexity, production volume, material requirements, and budget constraints to ensure optimal manufacturing outcomes.

Metal injection molding vs die casting Infographic

libmatt.com

libmatt.com