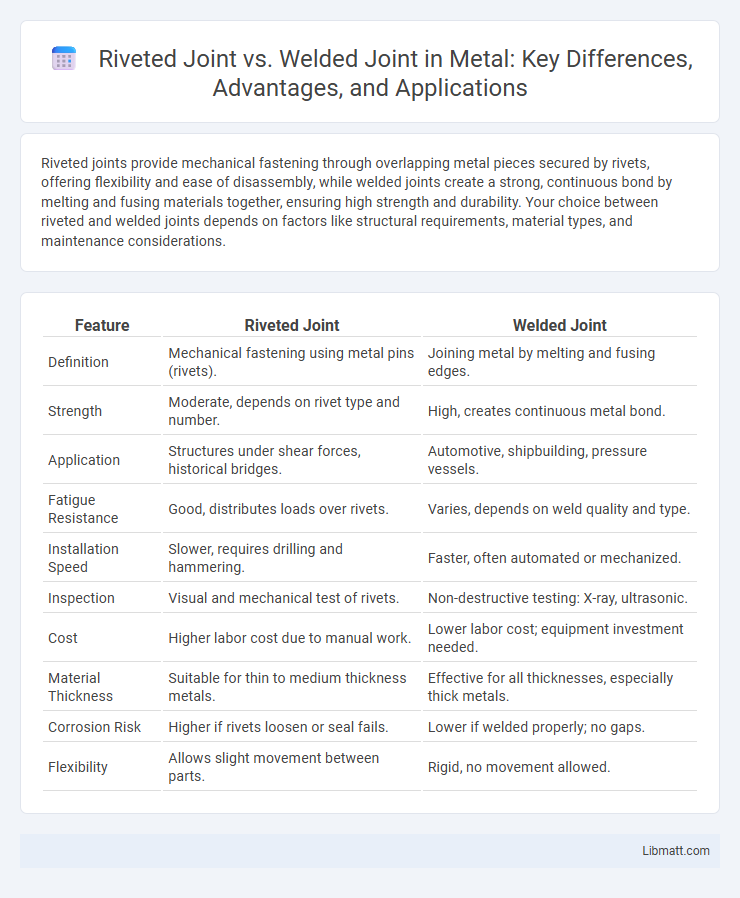

Riveted joints provide mechanical fastening through overlapping metal pieces secured by rivets, offering flexibility and ease of disassembly, while welded joints create a strong, continuous bond by melting and fusing materials together, ensuring high strength and durability. Your choice between riveted and welded joints depends on factors like structural requirements, material types, and maintenance considerations.

Table of Comparison

| Feature | Riveted Joint | Welded Joint |

|---|---|---|

| Definition | Mechanical fastening using metal pins (rivets). | Joining metal by melting and fusing edges. |

| Strength | Moderate, depends on rivet type and number. | High, creates continuous metal bond. |

| Application | Structures under shear forces, historical bridges. | Automotive, shipbuilding, pressure vessels. |

| Fatigue Resistance | Good, distributes loads over rivets. | Varies, depends on weld quality and type. |

| Installation Speed | Slower, requires drilling and hammering. | Faster, often automated or mechanized. |

| Inspection | Visual and mechanical test of rivets. | Non-destructive testing: X-ray, ultrasonic. |

| Cost | Higher labor cost due to manual work. | Lower labor cost; equipment investment needed. |

| Material Thickness | Suitable for thin to medium thickness metals. | Effective for all thicknesses, especially thick metals. |

| Corrosion Risk | Higher if rivets loosen or seal fails. | Lower if welded properly; no gaps. |

| Flexibility | Allows slight movement between parts. | Rigid, no movement allowed. |

Introduction to Riveted and Welded Joints

Riveted joints use metal pins or bolts to mechanically fasten two pieces together, providing high tensile strength and vibration resistance, commonly applied in bridge and shipbuilding structures. Welded joints fuse materials at a molecular level through heat or pressure, creating a seamless and strong connection ideal for heavy-duty construction and automotive industries. Understanding the distinctions between riveted and welded joints helps you select the best method for structural integrity, load requirements, and maintenance considerations.

Overview of Riveted Joints

Riveted joints consist of mechanical fasteners called rivets that hold two or more metal components together by creating a permanent connection through shear and tensile forces. These joints are commonly used in structural applications where disassembly is not required, providing high resistance to dynamic loads and vibrations. Your choice of riveted joints ensures a robust and durable bond, especially in bridges, aircraft, and heavy machinery where fatigue resistance is critical.

Overview of Welded Joints

Welded joints involve the fusion of metal parts through methods such as arc welding, MIG, or TIG, creating a continuous bond with high structural integrity. These joints offer superior strength, excellent resistance to shear and tensile forces, and typically provide a seamless finish ideal for pressure vessels, pipelines, and automotive frames. The heat-affected zone and the type of weld--fillet, butt, or groove--play crucial roles in determining the joint's mechanical properties and durability.

Key Differences Between Riveted and Welded Joints

Riveted joints use mechanical fasteners called rivets to join materials, providing high shear strength and ease of disassembly, while welded joints fuse materials together through heat, creating a continuous, permanent bond with superior tensile strength. Riveted joints are typically preferred in structures requiring vibration resistance and inspection, whereas welded joints offer superior airtightness and minimal material thickness. Key differences include load distribution, joint flexibility, and the requirement for skilled labor, with welding demanding higher technical precision and equipment.

Strength and Durability Comparison

Riveted joints provide reliable strength through mechanical fastening, making them ideal for applications subject to vibration and dynamic loads, while welded joints create a continuous metal bond that often results in superior tensile strength and resistance to fatigue. Welded joints typically offer higher durability and better performance under high stress or load conditions, although quality depends significantly on welding technique and material compatibility. Your choice between riveted and welded joints should consider the specific strength requirements and long-term durability needs of the structure or machinery.

Applications in Various Industries

Riveted joints are commonly utilized in the construction of bridges, aircraft structures, and heavy machinery where disassembly or inspection is required, offering strong mechanical fastening without altering material properties. Welded joints are favored in automotive manufacturing, shipbuilding, and pipeline industries for creating permanent, high-strength connections that ensure structural integrity under dynamic loads. Your choice between riveted and welded joints depends on factors such as load conditions, maintenance needs, and industry-specific standards.

Pros and Cons of Riveted Joints

Riveted joints offer high durability and excellent resistance to dynamic loads, making them ideal for structural applications such as bridges and aircraft. They allow for easy inspection and maintenance since individual rivets can be replaced without compromising the whole joint's integrity. However, riveted joints are labor-intensive to install, often heavier than welded joints, and prone to corrosion around the rivet holes if not properly sealed.

Pros and Cons of Welded Joints

Welded joints provide strong, continuous bonds that enhance structural integrity and reduce weight by eliminating the need for additional fasteners. They offer excellent resistance to fatigue and stress, making them ideal for critical applications in construction and manufacturing. However, welded joints can be susceptible to defects such as cracks and distortions, require skilled labor, and may involve higher initial costs compared to riveted joints.

Cost Analysis: Riveted vs Welded Joints

Riveted joints typically incur higher labor costs due to the manual process and longer installation time compared to welded joints, which benefit from automation and faster execution. Material costs for rivets and overlapping plates can increase the overall expense, whereas welded joints require less material but demand skilled labor and equipment investment. Maintenance costs for riveted joints may be greater because of potential loosening, while welded joints generally offer lower long-term repair expenses due to their continuous bond strength.

Conclusion: Choosing the Right Joint Type

Choosing the right joint type depends on factors such as load requirements, material properties, and environmental conditions. Riveted joints offer better vibration resistance and are suitable for structures requiring frequent inspection or maintenance, while welded joints provide superior strength and a more streamlined assembly, ideal for high-stress applications. Evaluating the specific project needs ensures optimal performance, durability, and cost-effectiveness in the final design.

Riveted Joint vs Welded Joint Infographic

libmatt.com

libmatt.com