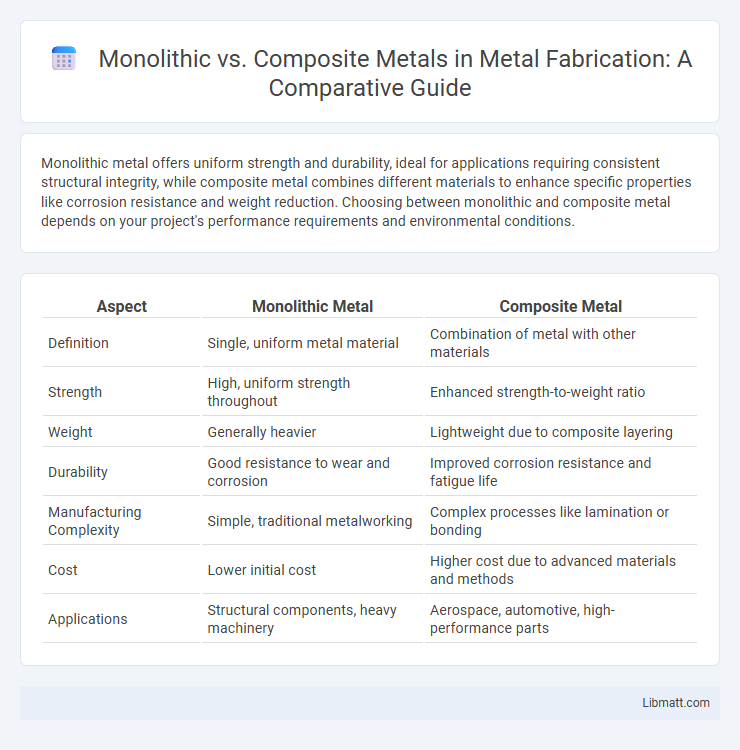

Monolithic metal offers uniform strength and durability, ideal for applications requiring consistent structural integrity, while composite metal combines different materials to enhance specific properties like corrosion resistance and weight reduction. Choosing between monolithic and composite metal depends on your project's performance requirements and environmental conditions.

Table of Comparison

| Aspect | Monolithic Metal | Composite Metal |

|---|---|---|

| Definition | Single, uniform metal material | Combination of metal with other materials |

| Strength | High, uniform strength throughout | Enhanced strength-to-weight ratio |

| Weight | Generally heavier | Lightweight due to composite layering |

| Durability | Good resistance to wear and corrosion | Improved corrosion resistance and fatigue life |

| Manufacturing Complexity | Simple, traditional metalworking | Complex processes like lamination or bonding |

| Cost | Lower initial cost | Higher cost due to advanced materials and methods |

| Applications | Structural components, heavy machinery | Aerospace, automotive, high-performance parts |

Introduction to Monolithic and Composite Metals

Monolithic metals consist of a single, uniform metal phase, offering consistent mechanical properties and excellent corrosion resistance ideal for structural applications. Composite metals combine two or more distinct metallic or metallic and non-metallic phases, engineered to enhance strength, toughness, and weight reduction beyond monolithic metals. These materials are critical in aerospace, automotive, and construction industries where tailored performance and durability are essential.

Defining Monolithic Metals

Monolithic metals consist of a single, homogeneous material structure without layers or composites, offering uniform properties such as strength, corrosion resistance, and conductivity throughout the entire piece. These metals are often preferred in applications requiring consistent mechanical performance and straightforward manufacturing processes. Understanding the defining characteristics of monolithic metals helps you choose the right material for projects demanding reliability and durability.

Understanding Composite Metals

Composite metals combine two or more distinct metallic materials to create a stronger, lighter, or more corrosion-resistant product compared to monolithic metals, which consist of a single metal throughout. Understanding composite metals involves analyzing their microstructures, such as metal matrix composites (MMCs) or laminated metals, that deliver enhanced mechanical properties tailored for specific applications like aerospace or automotive industries. Your choice between monolithic and composite metals should consider factors like strength-to-weight ratio, thermal stability, and cost-efficiency, demonstrating the advanced capability of composites in modern engineering challenges.

Key Differences Between Monolithic and Composite Metals

Monolithic metals consist of a single, uniform material with consistent mechanical properties throughout, while composite metals combine two or more distinct materials to enhance strength, corrosion resistance, or weight reduction. The key differences include their structure--monolithic metals have homogeneous composition, whereas composite metals feature heterogeneous layers or phases designed for specific functional performance. Composite metals often outperform monolithic metals in applications requiring tailored physical and chemical properties, such as aerospace and automotive industries.

Mechanical Properties Comparison

Monolithic metals typically exhibit uniform mechanical properties such as consistent tensile strength, ductility, and hardness due to their homogeneous microstructure. Composite metals, on the other hand, combine the properties of different materials, resulting in enhanced mechanical performance like increased stiffness, improved impact resistance, and tailored strength-to-weight ratios. The synergy in composite metals enables superior fatigue resistance and wear properties compared to monolithic counterparts.

Common Applications of Monolithic Metals

Monolithic metals are commonly used in aerospace components, automotive parts, and structural frameworks due to their uniform strength and high durability. Their ability to resist wear and corrosion makes them ideal for manufacturing engine blocks, turbine blades, and heavy machinery parts. Industries favor monolithic metals for applications requiring consistent mechanical properties and ease of fabrication.

Common Applications of Composite Metals

Composite metals are widely used in aerospace and automotive industries due to their superior strength-to-weight ratio and corrosion resistance compared to monolithic metals. These materials are ideal for manufacturing lightweight structural components, enhancing fuel efficiency and overall performance. You can also find composite metals in sports equipment and marine applications where durability and reduced weight are critical.

Advantages and Disadvantages of Each Type

Monolithic metal offers superior strength, uniformity, and ease of fabrication, making it ideal for heavy-duty applications but can be limited by weight and material costs. Composite metal combines different metals or layers to enhance corrosion resistance, flexibility, and strength-to-weight ratio, though it may face challenges in bonding consistency and long-term durability. Your choice between monolithic and composite metal depends on specific project requirements, balancing performance benefits against potential limitations.

Selection Criteria for Metal Materials

Selection criteria for metal materials hinge on factors such as mechanical strength, corrosion resistance, and thermal conductivity, which differ significantly between monolithic and composite metals. Monolithic metals offer uniformity and predictability in properties, making them ideal for applications requiring consistent performance under stress. Composite metals provide enhanced performance through tailored combinations of metals, optimizing strength-to-weight ratio and resistance to environmental degradation for specialized engineering needs.

Future Trends in Metal Engineering

Future trends in metal engineering emphasize the growing adoption of composite metals due to their superior strength-to-weight ratios and enhanced corrosion resistance compared to monolithic metals. Advances in additive manufacturing and nano-engineering enable the development of tailored composite materials with optimized microstructures for aerospace and automotive applications. The integration of smart alloys and self-healing composites is expected to revolutionize durability and maintenance in critical metal components.

Monolithic vs composite metal Infographic

libmatt.com

libmatt.com