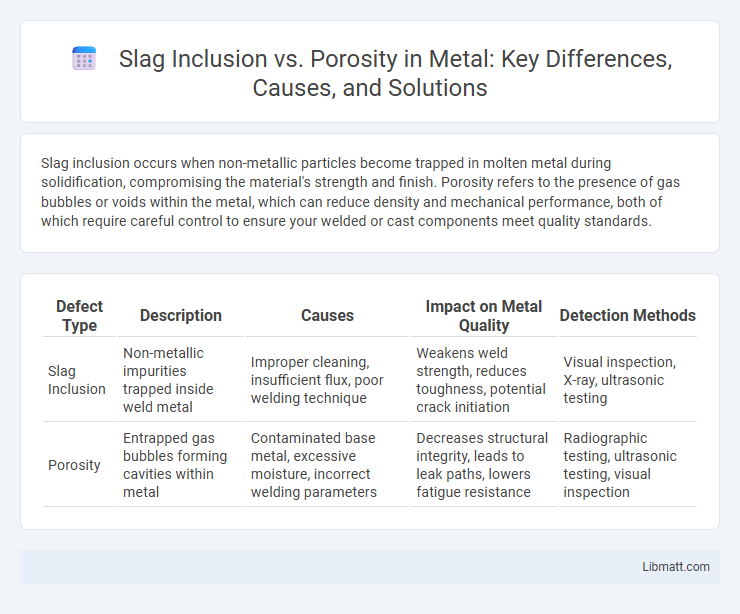

Slag inclusion occurs when non-metallic particles become trapped in molten metal during solidification, compromising the material's strength and finish. Porosity refers to the presence of gas bubbles or voids within the metal, which can reduce density and mechanical performance, both of which require careful control to ensure your welded or cast components meet quality standards.

Table of Comparison

| Defect Type | Description | Causes | Impact on Metal Quality | Detection Methods |

|---|---|---|---|---|

| Slag Inclusion | Non-metallic impurities trapped inside weld metal | Improper cleaning, insufficient flux, poor welding technique | Weakens weld strength, reduces toughness, potential crack initiation | Visual inspection, X-ray, ultrasonic testing |

| Porosity | Entrapped gas bubbles forming cavities within metal | Contaminated base metal, excessive moisture, incorrect welding parameters | Decreases structural integrity, leads to leak paths, lowers fatigue resistance | Radiographic testing, ultrasonic testing, visual inspection |

Introduction to Welding Defects

Slag inclusion and porosity are common welding defects that compromise the integrity of welds by creating internal discontinuities. Slag inclusion occurs when non-metallic solid material becomes trapped in the weld metal, while porosity arises from gas entrapment forming cavities within the weld. Understanding these defects is crucial for improving your weld quality and ensuring structural reliability in critical applications.

What is Slag Inclusion?

Slag inclusion is a welding defect characterized by non-metallic solid material, such as flux or slag, becoming trapped within the weld metal, leading to weakened joints and potential failure. This impurity forms when the slag from the welding process is not properly removed before the next weld pass, reducing the overall strength and ductility of your welds. Unlike porosity, which is caused by trapped gas bubbles, slag inclusions are solid contaminants that create discontinuities in the weld structure.

What is Porosity?

Porosity refers to the presence of tiny voids or gas pockets trapped within a metal during solidification, reducing its density and mechanical strength. It significantly affects the integrity and performance of welded or cast components by creating weak points prone to failure under stress. Unlike slag inclusions, which are non-metallic impurities, porosity primarily results from inadequate degassing or gas entrapment in the molten metal.

Causes of Slag Inclusion

Slag inclusion occurs primarily due to improper welding techniques, such as inadequate cleaning between passes or incorrect electrode angles that trap slag in the weld. Contaminants like rust, oil, or old weld splatter on the base metal can also cause slag to become entrapped during solidification. Unlike porosity, which is caused by gas entrapment, slag inclusion results from non-metallic solid impurities being incorporated into the weld metal.

Causes of Porosity

Porosity in metal casting primarily occurs due to trapped gases such as hydrogen, air, or moisture within the molten metal, which form small cavities as the metal solidifies. These gases can originate from contaminated molds, inadequate venting, or chemical reactions during melting. Understanding the causes of porosity helps you control the casting environment and improve the quality of your metal products.

Visual Differences: Slag Inclusion vs Porosity

Slag inclusion appears as elongated, irregularly shaped non-metallic particles trapped within the weld metal, often dark or metallic in color, contrasting sharply with the surrounding material. Porosity manifests as small, round gas pockets or voids dispersed throughout the weld, usually visible as tiny holes or bubbles on the weld surface. The key visual difference lies in slag inclusions being solid contaminants with defined shapes, while porosity consists of hollow voids lacking structural form.

Effects on Weld Strength and Integrity

Slag inclusions create non-metallic impurities within the weld, significantly reducing tensile strength and causing potential weld failure under stress. Porosity forms gas pockets that act as stress concentrators, decreasing the weld's fatigue resistance and overall structural integrity. Both defects compromise weld durability but slag inclusions generally cause more severe reductions in mechanical performance due to poor fusion and crack initiation points.

Detection Methods for Both Defects

Slag inclusion and porosity are detected using non-destructive testing methods such as ultrasonic testing, which identifies internal discontinuities by sound wave reflections, and radiographic testing, which captures X-ray or gamma-ray images highlighting density variations within metal. Visual inspection and magnetic particle testing assist in detecting surface-breaking slag inclusions, while computed tomography (CT) scanning offers precise 3D imaging to distinguish porosity from slag inclusions based on shape and distribution. Advanced automated image processing software enhances defect characterization by analyzing defect size, shape, and location, improving detection accuracy and defect categorization for quality control in welding and casting.

Prevention and Control Techniques

Slag inclusion prevention involves thorough cleaning of molten metal and proper furnace maintenance to eliminate impurities that cause non-metallic particles to embed in the casting. Porosity control relies on optimizing solidification rates, degassing procedures, and pressure application during casting to reduce gas entrapment and shrinkage cavities. Ensuring Your foundry utilizes advanced filtration systems and real-time process monitoring significantly enhances the quality by minimizing both slag inclusions and porosity defects.

Summary: Key Differences and Best Practices

Slag inclusion and porosity are common welding defects distinguished by their causes and appearance; slag inclusion is a non-metallic solid trapped within the weld metal, while porosity consists of gas pockets formed during solidification. Key differences include slag inclusion resulting from improper cleaning or welding technique, whereas porosity often arises from contamination or moisture. Your best practices to prevent these defects involve thorough joint cleaning, proper electrode selection, optimal welding parameters, and controlled environmental conditions.

Slag Inclusion vs Porosity Infographic

libmatt.com

libmatt.com