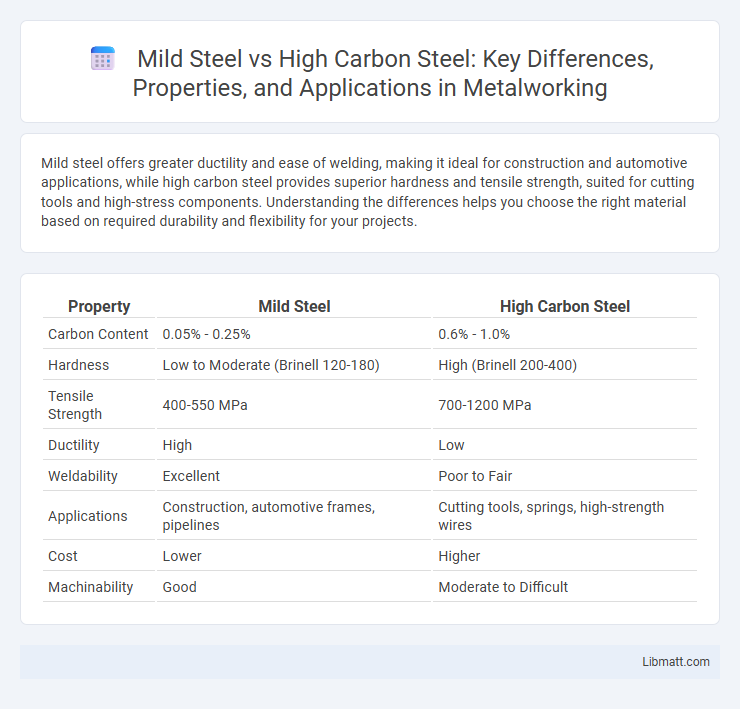

Mild steel offers greater ductility and ease of welding, making it ideal for construction and automotive applications, while high carbon steel provides superior hardness and tensile strength, suited for cutting tools and high-stress components. Understanding the differences helps you choose the right material based on required durability and flexibility for your projects.

Table of Comparison

| Property | Mild Steel | High Carbon Steel |

|---|---|---|

| Carbon Content | 0.05% - 0.25% | 0.6% - 1.0% |

| Hardness | Low to Moderate (Brinell 120-180) | High (Brinell 200-400) |

| Tensile Strength | 400-550 MPa | 700-1200 MPa |

| Ductility | High | Low |

| Weldability | Excellent | Poor to Fair |

| Applications | Construction, automotive frames, pipelines | Cutting tools, springs, high-strength wires |

| Cost | Lower | Higher |

| Machinability | Good | Moderate to Difficult |

Introduction to Mild Steel and High Carbon Steel

Mild steel contains approximately 0.05-0.25% carbon, offering ductility and weldability ideal for construction and automotive applications. High carbon steel, with 0.6-1.0% carbon content, provides greater hardness and tensile strength, making it suitable for cutting tools and high-strength wires. Understanding the differences in carbon content helps you select the right material for durability or flexibility in your projects.

Chemical Composition Differences

Mild steel typically contains around 0.05% to 0.25% carbon, with higher amounts of iron and limited amounts of other elements such as manganese and silicon, making it more ductile and malleable. High carbon steel contains approximately 0.6% to 1.0% carbon, which increases hardness and tensile strength but reduces flexibility. Your choice between mild and high carbon steel depends on the desired balance between strength, hardness, and malleability for specific applications.

Mechanical Properties Comparison

Mild steel offers lower tensile strength and hardness but superior ductility and weldability compared to high carbon steel, which excels in hardness and wear resistance due to its higher carbon content. High carbon steel typically has tensile strength ranging from 750 to 1000 MPa, while mild steel ranges between 400 to 550 MPa, making the former ideal for tools and cutting implements. Your choice depends on whether toughness or hardness is more critical for the application, as mild steel deforms easily under stress, whereas high carbon steel resists deformation but can be more brittle.

Strength and Hardness Analysis

High carbon steel exhibits significantly greater hardness and tensile strength compared to mild steel due to its higher carbon content, typically ranging from 0.6% to 1.0%. Mild steel, with carbon content around 0.05% to 0.25%, offers lower hardness but superior ductility and ease of welding. For applications requiring maximum durability and wear resistance, high carbon steel is preferable, while mild steel suits scenarios where flexibility and easy machining benefit your project.

Applications and Common Uses

Mild steel is widely used in construction, automotive body panels, and manufacturing of pipes due to its ductility and ease of welding. High carbon steel excels in applications requiring hardness and wear resistance, such as cutting tools, springs, and high-strength wires. Your choice between these steels depends on the need for flexibility versus durability in specific industrial or mechanical tasks.

Workability and Machinability

Mild steel offers superior workability and machinability due to its lower carbon content, making it easier to cut, shape, and weld for various manufacturing processes. High carbon steel, with its increased hardness and strength, poses greater challenges during machining and often requires specialized tools and techniques. Your choice between these steels should consider the balance between ease of fabrication and final product durability.

Weldability and Joinability

Mild steel offers superior weldability compared to high carbon steel due to its lower carbon content, which minimizes the risk of cracking and distortion during welding. High carbon steel requires preheating and controlled cooling to ensure proper joinability and to avoid brittle welds, making the welding process more complex and time-consuming. Your choice between these materials should consider the ease of welding and the specific application requirements.

Corrosion Resistance Differences

Mild steel typically offers lower corrosion resistance compared to high carbon steel due to its lower carbon content and higher susceptibility to oxidation. High carbon steel, while stronger and harder, is more prone to rust without proper protective coatings or treatments. Understanding these differences helps you select the appropriate steel type for environments where corrosion resistance is critical.

Cost and Availability

Mild steel is significantly more affordable and widely available due to its lower carbon content and simpler production process, making it ideal for mass manufacturing and construction projects. High carbon steel, containing approximately 0.6% to 1.0% carbon, is more expensive and less readily available because of its specialized heat treatment requirements and enhanced hardness properties. The cost disparity impacts procurement decisions, with mild steel preferred for budget-sensitive applications and high carbon steel selected for durability and wear resistance despite higher expenses.

Choosing the Right Steel for Your Project

Mild steel offers excellent ductility and weldability, making it ideal for construction and general fabrication projects requiring ease of shaping and joining. High carbon steel provides superior hardness and tensile strength, suitable for tools, knives, and applications demanding wear resistance. Understanding your project's requirements for strength, flexibility, and machinability will help you select the right steel type for optimal performance.

mild steel vs high carbon steel Infographic

libmatt.com

libmatt.com