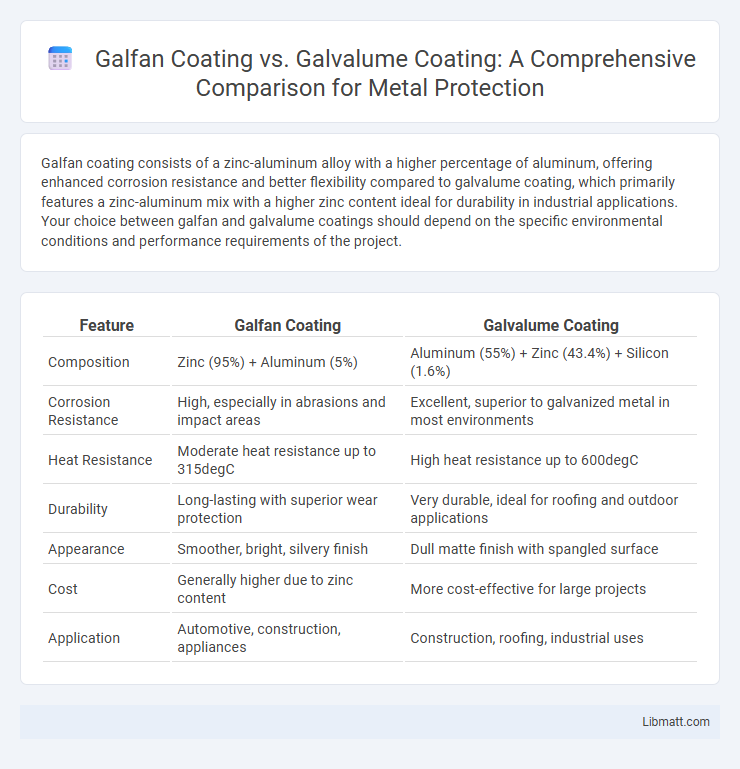

Galfan coating consists of a zinc-aluminum alloy with a higher percentage of aluminum, offering enhanced corrosion resistance and better flexibility compared to galvalume coating, which primarily features a zinc-aluminum mix with a higher zinc content ideal for durability in industrial applications. Your choice between galfan and galvalume coatings should depend on the specific environmental conditions and performance requirements of the project.

Table of Comparison

| Feature | Galfan Coating | Galvalume Coating |

|---|---|---|

| Composition | Zinc (95%) + Aluminum (5%) | Aluminum (55%) + Zinc (43.4%) + Silicon (1.6%) |

| Corrosion Resistance | High, especially in abrasions and impact areas | Excellent, superior to galvanized metal in most environments |

| Heat Resistance | Moderate heat resistance up to 315degC | High heat resistance up to 600degC |

| Durability | Long-lasting with superior wear protection | Very durable, ideal for roofing and outdoor applications |

| Appearance | Smoother, bright, silvery finish | Dull matte finish with spangled surface |

| Cost | Generally higher due to zinc content | More cost-effective for large projects |

| Application | Automotive, construction, appliances | Construction, roofing, industrial uses |

Introduction to Galfan and Galvalume Coatings

Galfan coating consists of a zinc-aluminum alloy with approximately 95% zinc and 5% aluminum, providing enhanced corrosion resistance and flexibility compared to traditional galvanizing. Galvalume coating combines about 55% aluminum, 43.5% zinc, and 1.5% silicon, offering superior heat resistance and durability in harsh environments. Understanding the differences between Galfan and Galvalume coatings helps you choose the right protective layer for metal surfaces based on performance requirements and environmental exposure.

Chemical Composition and Structure

Galfan coating consists primarily of zinc with about 5% aluminum and a small percentage of rare earth elements, providing a unique alloy that enhances corrosion resistance and flexibility. Galvalume coating contains roughly 55% aluminum, 43.4% zinc, and 1.6% silicon, forming a metallurgical bond that offers superior heat resistance and durability. Your choice between these coatings depends on the specific chemical composition and structural properties required for optimal performance in various environmental conditions.

Corrosion Resistance Comparison

Galfan coating, composed primarily of zinc with about 5% aluminum and 1-3% magnesium, offers superior corrosion resistance compared to Galvalume, which contains approximately 55% aluminum, 43.5% zinc, and 1.5% silicon. The magnesium content in Galfan enhances protection against saltwater and chloride environments, making it ideal for coastal applications, whereas Galvalume provides excellent oxidation resistance suitable for high-temperature environments. Studies show Galfan's corrosion rate is significantly lower in marine atmospheres, extending the service life of coated steel in aggressive conditions.

Mechanical Properties and Performance

Galfan coating, composed primarily of zinc with about 5% aluminum and 0.5% magnesium, offers enhanced mechanical properties including improved elongation and ductility compared to Galvalume coating, making it ideal for applications requiring superior formability. Galvalume coating combines approximately 55% aluminum, 43.5% zinc, and 1.5% silicon, providing excellent corrosion resistance and thermal performance but slightly lower resistance to mechanical deformation than Galfan. The performance advantage of Galfan lies in its ability to maintain coating integrity under bending and stretch forming, while Galvalume excels in high-temperature environments and long-term durability against atmospheric and industrial corrosion.

Applications in Industry

Galfan coating, composed primarily of zinc and aluminum with small amounts of rare earth elements, offers superior corrosion resistance and flexibility, making it ideal for automotive components, roofing, and household appliances. Galvalume coating, which consists of a zinc-aluminum alloy with silicon, excels in high-temperature environments and is widely used in construction materials, particularly for steel roofing and siding in industrial buildings. Your choice between Galfan and Galvalume coatings will depend on the specific performance requirements, such as exposure conditions and durability needs, within your industry application.

Durability and Lifespan

Galfan coating, composed of 95% zinc and 5% aluminum, offers superior corrosion resistance and longer lifespan compared to traditional galvanizing, making it highly durable in harsh environments. Galvalume coating contains approximately 55% aluminum, 43.5% zinc, and 1.5% silicon, providing excellent protection against rust and thermal stability but typically has a shorter lifespan than Galfan in extreme corrosion conditions. Both coatings enhance steel durability, but Galfan is preferred for environments requiring extended durability and resistance to mechanical abrasion.

Cost Analysis and Economic Considerations

Galfan coating typically offers superior corrosion resistance compared to Galvalume, which can translate into longer service life and reduced maintenance costs for your projects. While Galvanized sheet steel costs less upfront, Galfan's premium pricing is justified by its enhanced durability and performance in harsh environments. Evaluating the total cost of ownership, including replacement frequency, often makes Galfan a more economical choice despite higher initial expenses.

Environmental Impact and Sustainability

Galfan coating, composed primarily of zinc and approximately 5% aluminum, offers enhanced corrosion resistance while utilizing less zinc, reducing environmental impact through lower zinc mining and processing emissions compared to Galvalume coating, which contains about 55% aluminum, 43.5% zinc, and 1.5% silicon. Galfan's longer lifespan and improved durability reduce replacement frequency, minimizing waste and resource consumption, whereas Galvalume's higher aluminum content provides excellent heat reflectivity and corrosion resistance but involves a more energy-intensive production process. Both coatings contribute to sustainability through recyclability, but Galfan's balanced alloy composition presents a more eco-efficient option in zinc-aluminum coated steel applications.

Maintenance and Long-Term Performance

Galfan coating, composed of zinc and aluminum, provides superior corrosion resistance and requires less maintenance than Galvalume coating, which is primarily aluminum-zinc based. Your structures benefit from Galfan's enhanced durability in harsh environments, extending the lifespan with minimal upkeep. Over time, Galfan outperforms Galvalume in resisting rust and preserving structural integrity, making it a cost-effective choice for long-term applications.

Choosing the Right Coating for Your Needs

Galfan coating offers superior corrosion resistance with a zinc-aluminum alloy composition, making it ideal for applications exposed to harsh weather and salty environments. Galvalume coating combines aluminum, zinc, and silicon to provide excellent heat reflectivity and durability, suitable for roofing and siding in moderate climates. Your choice depends on whether enhanced corrosion protection or heat resistance is more critical for your specific project requirements.

Galfan Coating vs Galvalume Coating Infographic

libmatt.com

libmatt.com