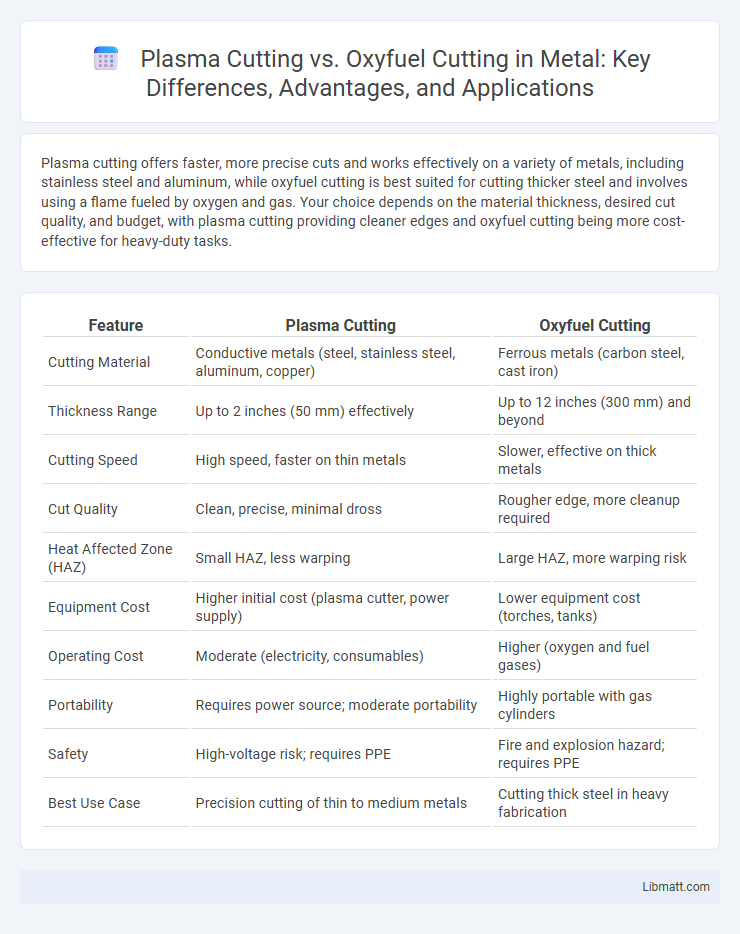

Plasma cutting offers faster, more precise cuts and works effectively on a variety of metals, including stainless steel and aluminum, while oxyfuel cutting is best suited for cutting thicker steel and involves using a flame fueled by oxygen and gas. Your choice depends on the material thickness, desired cut quality, and budget, with plasma cutting providing cleaner edges and oxyfuel cutting being more cost-effective for heavy-duty tasks.

Table of Comparison

| Feature | Plasma Cutting | Oxyfuel Cutting |

|---|---|---|

| Cutting Material | Conductive metals (steel, stainless steel, aluminum, copper) | Ferrous metals (carbon steel, cast iron) |

| Thickness Range | Up to 2 inches (50 mm) effectively | Up to 12 inches (300 mm) and beyond |

| Cutting Speed | High speed, faster on thin metals | Slower, effective on thick metals |

| Cut Quality | Clean, precise, minimal dross | Rougher edge, more cleanup required |

| Heat Affected Zone (HAZ) | Small HAZ, less warping | Large HAZ, more warping risk |

| Equipment Cost | Higher initial cost (plasma cutter, power supply) | Lower equipment cost (torches, tanks) |

| Operating Cost | Moderate (electricity, consumables) | Higher (oxygen and fuel gases) |

| Portability | Requires power source; moderate portability | Highly portable with gas cylinders |

| Safety | High-voltage risk; requires PPE | Fire and explosion hazard; requires PPE |

| Best Use Case | Precision cutting of thin to medium metals | Cutting thick steel in heavy fabrication |

Introduction to Plasma Cutting and Oxyfuel Cutting

Plasma cutting uses an accelerated jet of hot plasma to precisely cut electrically conductive metals, offering high speed and clean edges ideal for steel, aluminum, and stainless steel. Oxyfuel cutting employs a combination of oxygen and fuel gases to produce a flame that heats and oxidizes steel for cutting thicker materials but with slower speeds and rougher edges. Your choice depends on material type, thickness, and the required cut quality, with plasma preferred for precision and oxyfuel for heavy-duty, thicker steel cutting.

How Plasma Cutting Works

Plasma cutting works by using an electrical arc to ionize gas, creating a high-temperature plasma jet that melts and blows away metal at the cutting point. This process enables precise, fast cutting of electrically conductive materials such as steel, aluminum, and copper. The plasma arc reaches temperatures up to 30,000degF, allowing it to cut through thick metals with clean edges and minimal slag compared to oxyfuel cutting.

How Oxyfuel Cutting Works

Oxyfuel cutting operates by using a combination of fuel gas and oxygen to produce a high-temperature flame that heats the metal to its ignition temperature, followed by a jet of pure oxygen that oxidizes and blows away the molten metal. This exothermic reaction allows for cutting through thick steel with precision, typically up to 12 inches in industrial applications. The process relies on the metal's ability to oxidize, making it particularly effective for ferrous metals but less suitable for non-ferrous materials.

Materials Suitable for Plasma Cutting

Plasma cutting excels at cutting conductive metals such as steel, stainless steel, aluminum, brass, and copper with precision and speed. Unlike oxyfuel cutting, which works best on thicker ferrous metals, plasma cutting handles a wide range of metal thicknesses, including thin and non-ferrous materials. The versatility of plasma cutting makes it ideal for applications in fabrication, automotive repair, and industrial manufacturing.

Materials Suitable for Oxyfuel Cutting

Oxyfuel cutting is best suited for ferrous metals such as mild steel, carbon steel, and low alloy steel, typically ranging from 1/8 inch up to several inches thick. It is ineffective on non-ferrous metals like aluminum, stainless steel, or copper due to their high thermal conductivity and oxidation resistance. The process relies on combustion of the metal, making it ideal for cutting thick steel plates in construction, shipbuilding, and heavy fabrication industries.

Cut Quality: Plasma Cutting vs Oxyfuel

Plasma cutting delivers superior cut quality with precise, clean edges and minimal slag, making it ideal for detailed metal fabrication and thinner materials. Oxyfuel cutting tends to produce rougher edges with more dross and is better suited for thicker steel plates where cut precision is less critical. The advanced technology in plasma cutting enables higher accuracy and finer tolerances compared to oxyfuel, which relies on combustion and results in more thermal distortion.

Speed and Efficiency Comparison

Plasma cutting offers significantly faster cutting speeds than oxyfuel cutting, especially on thinner metals, due to its high-temperature ionized gas arc that melts and blows away material swiftly. Oxyfuel cutting is more efficient on thicker steel plates but slows down considerably on thinner metals and non-ferrous materials. Your choice depends on balancing cutting speed and material type for optimal efficiency.

Cost Analysis: Plasma and Oxyfuel Cutting

Plasma cutting generally incurs higher initial equipment costs and electricity expenses but offers lower operating costs through faster cutting speeds and reduced material waste compared to oxyfuel cutting. Oxyfuel cutting requires lower upfront investment and uses readily available fuel gases like acetylene and oxygen, yet its slower cut rates and higher consumable use often increase total operating expenses over time. Evaluating cost-effectiveness depends on factors such as material thickness, production volume, and fuel availability, with plasma cutting being more economical for thin metals and high-precision tasks, while oxyfuel remains cost-efficient for thicker steel and low-volume applications.

Safety Considerations for Both Methods

Plasma cutting generates intense heat and ultraviolet radiation, requiring protective gear such as gloves, face shields, and flame-resistant clothing to prevent burns and eye damage. Oxyfuel cutting involves open flames and high-pressure oxygen, necessitating careful handling of gas cylinders, proper ventilation, and fire-resistant clothing to reduce the risk of explosions and inhalation of harmful gases. Both methods demand strict adherence to safety protocols, including maintaining a clear workspace and using appropriate personal protective equipment (PPE) to minimize hazards.

Choosing the Right Cutting Method

Choosing the right cutting method depends on the material thickness and desired precision; plasma cutting excels with conductive metals up to 1 inch thick, offering faster, cleaner cuts and minimal heat distortion. Oxyfuel cutting works best for thicker steel plates over 1 inch, leveraging a chemical reaction to cut efficiently but with slower speed and more slag. Evaluating your project requirements and material type ensures you select the optimal technology for quality and cost-effectiveness.

plasma cutting vs oxyfuel cutting Infographic

libmatt.com

libmatt.com