Seam welding creates continuous, airtight joints ideal for cylindrical or sheet metal applications, while spot welding joins overlapping metal sheets at discrete points, offering quick and strong connections. Choosing the right method depends on your project's requirements for strength, appearance, and production speed.

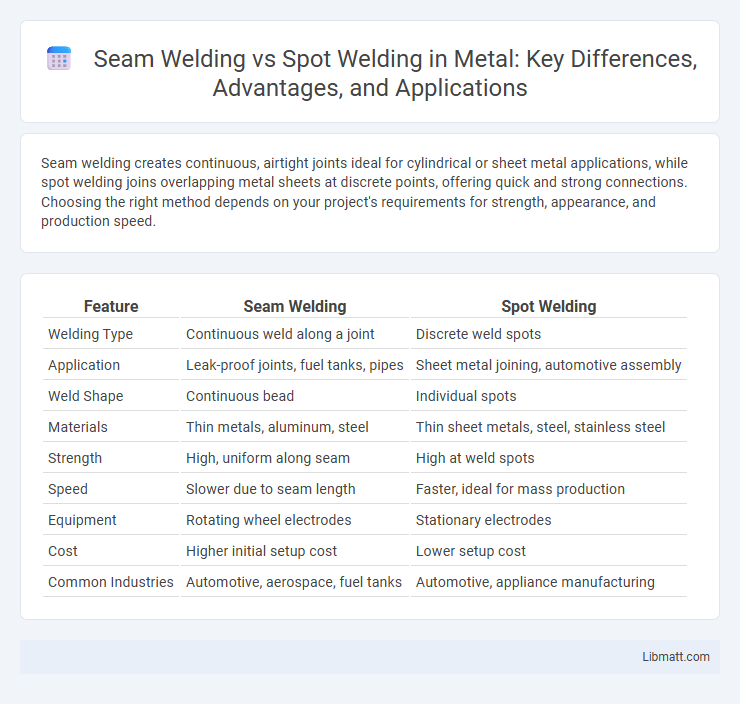

Table of Comparison

| Feature | Seam Welding | Spot Welding |

|---|---|---|

| Welding Type | Continuous weld along a joint | Discrete weld spots |

| Application | Leak-proof joints, fuel tanks, pipes | Sheet metal joining, automotive assembly |

| Weld Shape | Continuous bead | Individual spots |

| Materials | Thin metals, aluminum, steel | Thin sheet metals, steel, stainless steel |

| Strength | High, uniform along seam | High at weld spots |

| Speed | Slower due to seam length | Faster, ideal for mass production |

| Equipment | Rotating wheel electrodes | Stationary electrodes |

| Cost | Higher initial setup cost | Lower setup cost |

| Common Industries | Automotive, aerospace, fuel tanks | Automotive, appliance manufacturing |

Introduction to Seam Welding and Spot Welding

Seam welding uses continuous or overlapping welds to create airtight or watertight joints, commonly applied in manufacturing fuel tanks and pipes. Spot welding joins two metal sheets together at discrete points through localized heat generated by electrical resistance, frequently used in automotive body assembly. Both techniques utilize electric current to melt metal but differ in weld pattern and application scope.

Fundamental Principles of Seam Welding

Seam welding utilizes continuous, overlapping spot welds created by rotating wheels that apply pressure and electric current simultaneously, forming a leak-tight, continuous joint ideal for cylindrical or sheet metal assemblies. In contrast to spot welding, which produces discrete weld points, seam welding's fundamental principle relies on the progressive movement and consistent energy supply to join materials along a linear path. Your choice between these methods depends on the requirements for joint strength, appearance, and fluid-tight properties in manufacturing applications.

Key Features of Spot Welding

Spot welding utilizes electrical resistance to join metal sheets at specific points, creating weld spots through intense heat generated by electric current. It is highly efficient for joining thin metal layers quickly, making it ideal for automotive and manufacturing industries. Your production process benefits from its strong, precise welds and minimal material distortion.

Equipment and Technology Comparison

Seam welding utilizes a continuous rotary electrode to create a uniform, water-tight seam ideal for cylindrical components, while spot welding relies on stationary copper electrodes that apply pressure and current to localized points for rapid joint formation. Seam welding machines are typically equipped with precise roll-driven systems and integrated cooling mechanisms to ensure consistent weld quality over extended lengths. Spot welding technology emphasizes high-current transformers and timed control units that enable quick, repetitive spot welds suitable for sheet metal assemblies.

Strength and Durability of Welds

Seam welding produces continuous welds that offer superior strength and durability compared to spot welding, which creates discrete weld points. The continuous nature of seam welds distributes stress more evenly across the joint, enhancing resistance to fatigue and leakage. In contrast, spot welds may be more susceptible to failure under cyclic loads due to their localized weld zones.

Material Compatibility and Suitability

Seam welding is highly suitable for materials like stainless steel and aluminum, offering continuous, airtight joints ideal for applications requiring corrosion resistance. Spot welding excels with low to medium carbon steels, providing rapid, localized welds suited for automotive body panels and thin sheet metals. Material thickness and thermal conductivity significantly influence the choice between these techniques to ensure optimal weld quality and structural integrity.

Speed and Efficiency: Seam vs Spot Welding

Seam welding offers continuous welds, making it highly efficient for creating airtight or watertight joints at high speeds, ideal for applications such as automotive fuel tanks and metal containers. Spot welding, while generally faster per weld, joins materials at discrete points, offering rapid cycle times suitable for mass production but less suited for continuous sealing. The overall speed advantage depends on the application's need for continuous versus localized bonding, with seam welding excelling in efficiency for linear joints and spot welding optimizing speed for repetitive, isolated welds.

Common Applications in Industry

Seam welding is widely used in industries requiring airtight or watertight joints, such as manufacturing fuel tanks, boilers, and metal containers where continuous, leak-proof seams are essential. Spot welding is common in automotive assembly lines and sheet metal fabrication, providing strong, localized joints ideal for joining overlapping metal sheets quickly and efficiently. Your choice depends on whether you need continuous seams or discrete weld points tailored to specific industrial applications.

Advantages and Disadvantages

Seam welding provides continuous, airtight joints ideal for fuel tanks and pipes, offering superior strength and corrosion resistance compared to spot welding, which produces discrete weld points suited for quick assembly of sheet metal parts. Spot welding excels in speed and cost-efficiency for mass production but may suffer from weaker joint integrity and less flexibility in seam design. Your choice depends on the application's need for durability versus manufacturing efficiency.

Choosing the Right Welding Method

Seam welding creates continuous, watertight joints ideal for applications requiring airtight or liquid-tight seals, while spot welding is best suited for joining overlapping metal sheets quickly with point-specific welds. Industries prioritizing durability and corrosion resistance often select seam welding for its consistent welds along entire seams, whereas automotive manufacturing favors spot welding for its speed and efficiency in assembly lines. Selecting the right method depends on factors like material thickness, joint type, and production volume to balance strength, cost, and weld quality.

Seam welding vs spot welding Infographic

libmatt.com

libmatt.com